8-39

TMS800E SERVICE MANUAL UNDERCARRIAGE

Published 01-29-2014, Control # 496-00

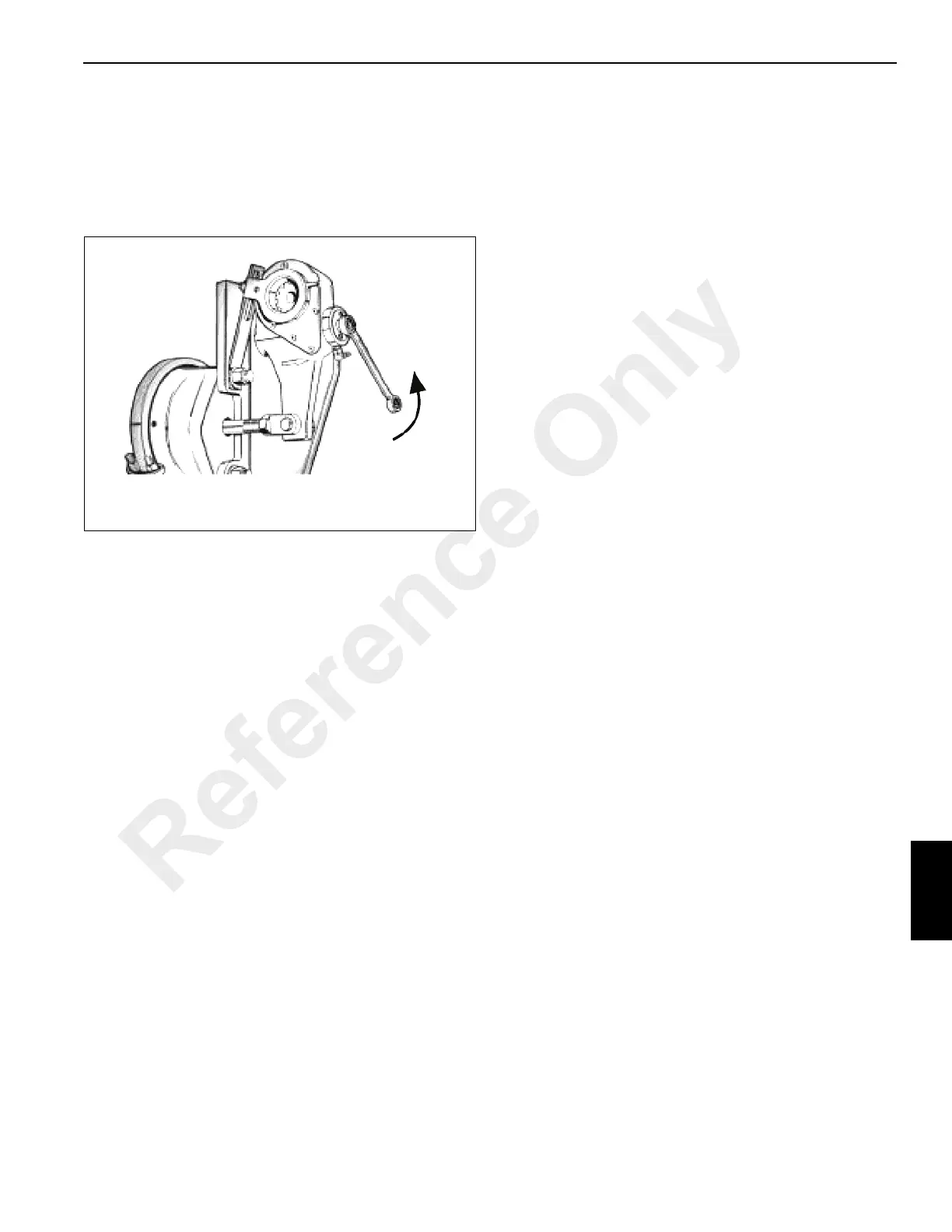

7. Rotate the adjusting hex approximately 1/8 turn in the

direction required and re-measure the stroke. Continue

this process until the stroke is within limits. A minimum of

17.6 Nm (13 lb ft) of torque is required to turn the hex

and overcome the internal clutch. A ratcheting noise will

be heard. Do not use an impact wrench or internal

damage will occur (Figure 8-50).

8. With brakes released, check installation indicator

(Figure 8-49) and (Figure 8-50) to determine proper

adjustment.

9. If installation indicator is not positioned properly, refer to

(Figure 8-50). Loosen fastener holding indicator to

anchor bracket, rotate indicator as required and

retighten fastener.

10. Uncage spring brake if so equipped.

AUTOMATIC SLACK ADJUSTER (REAR)

Description

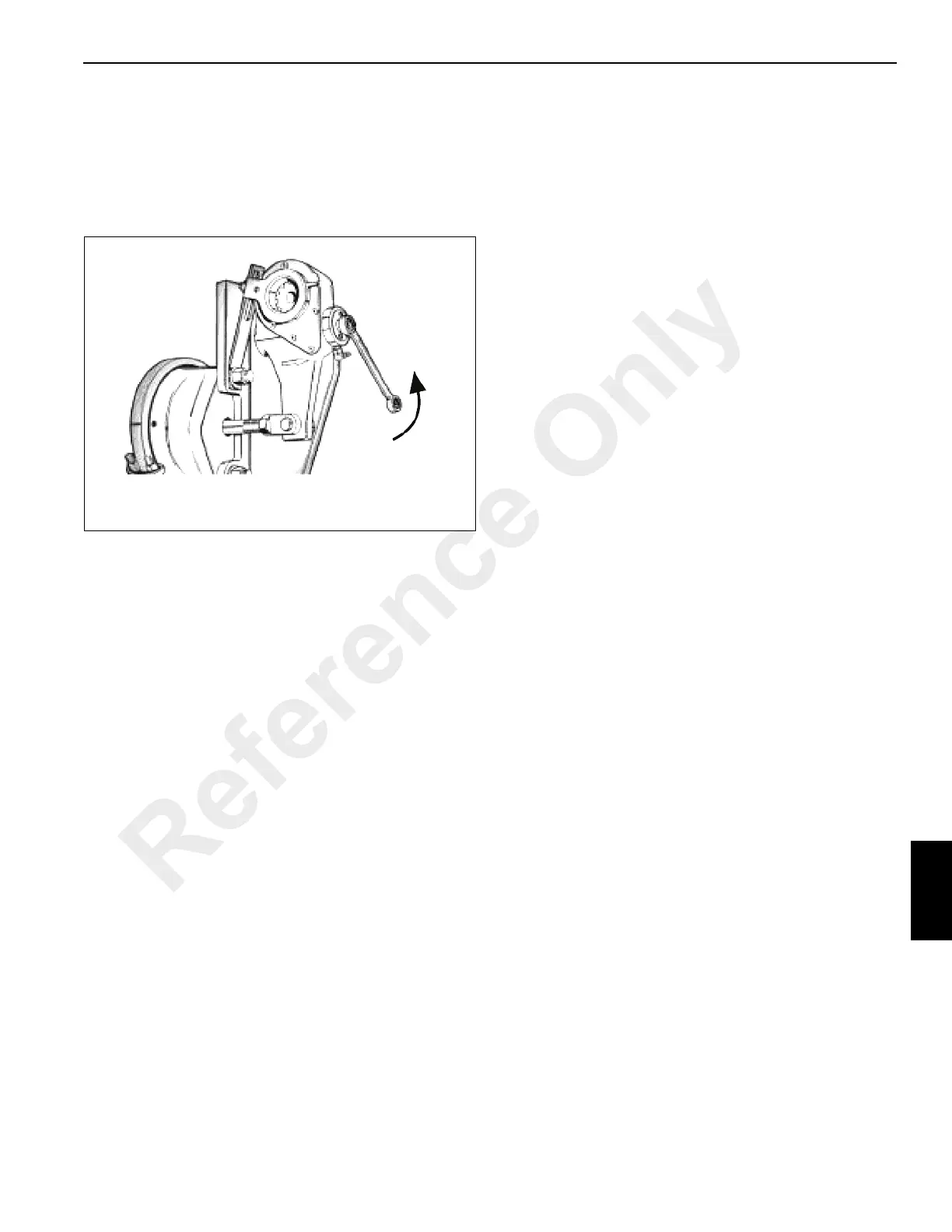

The automatic slack adjuster (see Figure 8-51)

compensates for normal wear in the brake shoe linings by

maintaining a nominal clearance between the lining and

drum. These are preset at the manufacturer’s factory.

When the brake is applied the slack adjuster’s rotation

moves the shoes and linings into contact with the brake

drum. This movement also lifts the actuation rod through a

pre-set, free travel dimension that is normal lining to drum

clearance. Continuing the brake application rotates a one-

way clutch in its over riding mode, and at the same time

causes the large coil spring to deflect at a specific force. This

spring deflection allows the worm to move axially. The clutch

movement is restricted by a machine step. This movement

fully disengages the drive clutch from the worm and prevents

unwanted brake adjustment from occurring.

When the brake is released, the large coil spring resumes its

original load and position, which allows the drive clutch to re-

engage. Simultaneous to drive clutch re-engagement, if any

lining wear has occurred, the actuation rod rotates the one

way adjuster clutch an amount proportional to lining wear.

This motion rotates the worm, worm wheel, and the S-cam

shaft resulting in adjustment of the brakes.

Reference Only

Loading...

Loading...