8-10

Published 01-29-2014, Control # 496-00

UNDERCARRIAGE TMS800E SERVICE MANUAL

3. To ensure proper adjustment, drive the front wheels onto

greased plates or a suitable turntable so that the friction

between the tires and ground is reduced.

4. If greased plates are not available, raise the crane 3.75

cm (1.5 in) from the static height by lowering the

outrigger jack cylinders. This will allow adjustment of the

drag links without damage, but will require rechecking

the alignment after the axles are fully loaded

5. Crack the fittings on each steer cylinder and turn the

steering wheel from stop to stop, bleeding the cylinders

until there is no air. Tighten fittings.

6. Install the relay arm rig pins. Refer to Drag Link

Installation and Axle Synchronization in this section.

CAUTION

Do not attempt to adjust the axle drag links or the tie rod

ends while the full weight of the crane is on the axles

unless the tires are on greased plates or the crane is on

outriggers. Failure to do so may cause component

damage.

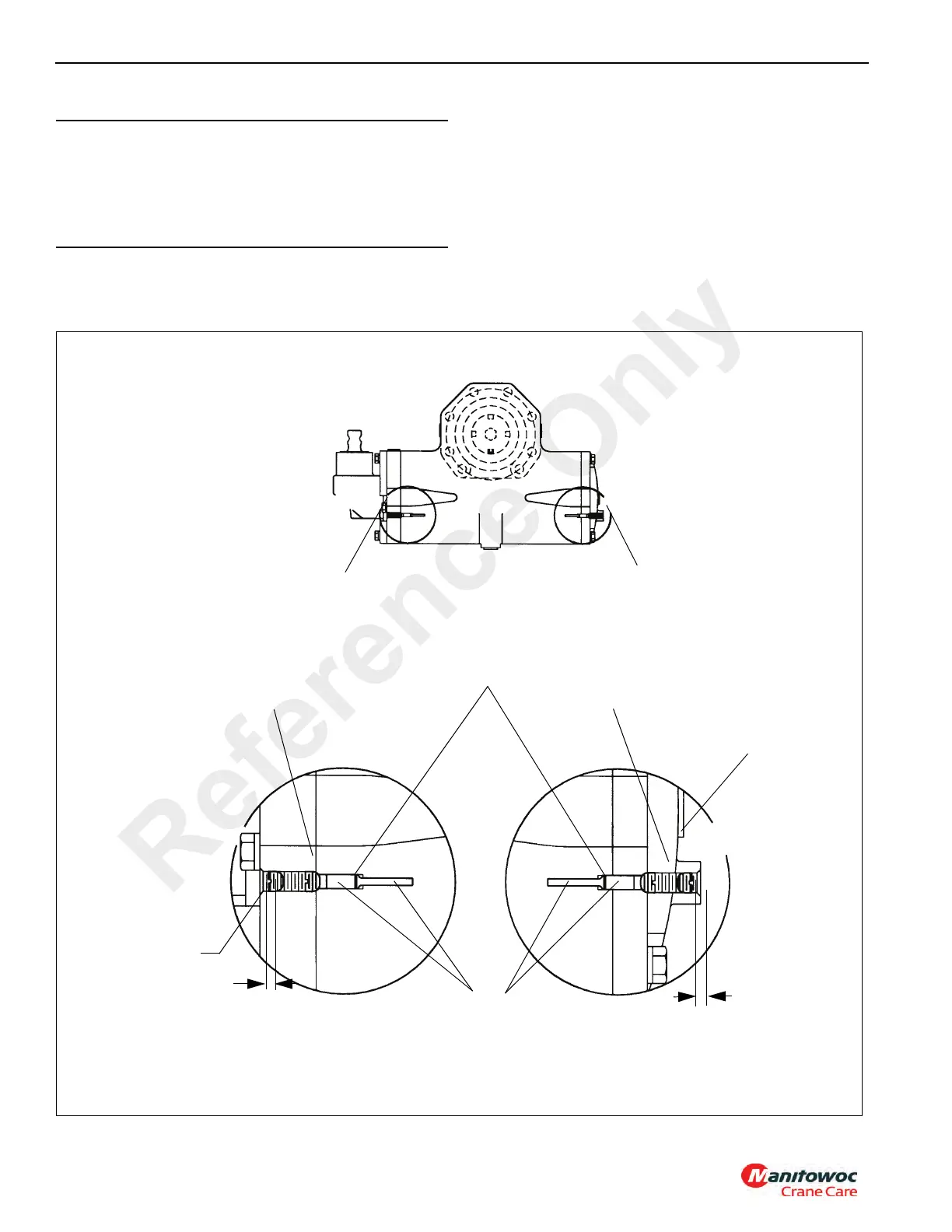

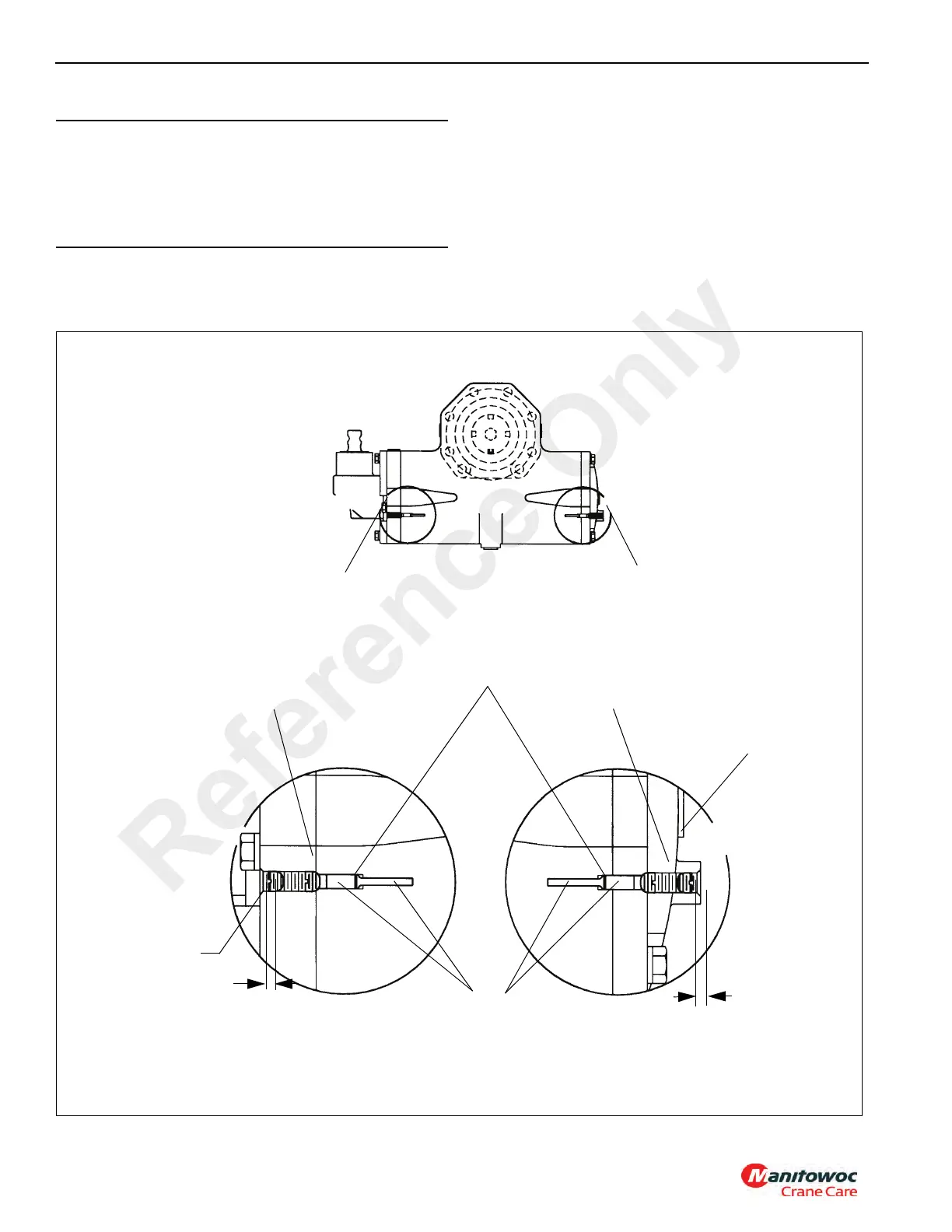

DETAIL A

DETAIL B

DETAIL A

DETAIL B

Rear plunger adjust on right hand turn.

Screw in to decrease travel; screw out to

increase travel.

Front plunger adjust on left hand turn.

Screw in to decrease travel; screw out to

increase travel.

Plunger

Plunger O-ring

Housing

Housing

Prior to gear installation, screw

plunger in until it bottoms out in

NOTE: Plunger(s) must not be screwed out beyond

this depth. Damage could result.

FIGURE 8-9

Prior to gear installation, screw

plunger in until it bottoms out in

4mm (0.16 in) min. acceptable

plunger head depth

4mm (0.16 in) min. acceptable

plunger head depth

Reference Only

Loading...

Loading...