Chapter 3 Engine Section 4 Inspection and maintenance of engine componenets

3—34

Inner diameter of small end of connecting rod

Measure the inner diameter of the small end of the

connecting rod with an inner diameter micrometer.

If the inner diameter of the small end of the connecting rod

exceeds the service limit, replace the connecting rod.

As in Fig.3.4.63

Tools: inside micrometer

Use limit:φ

012.0

004.0

14

mm

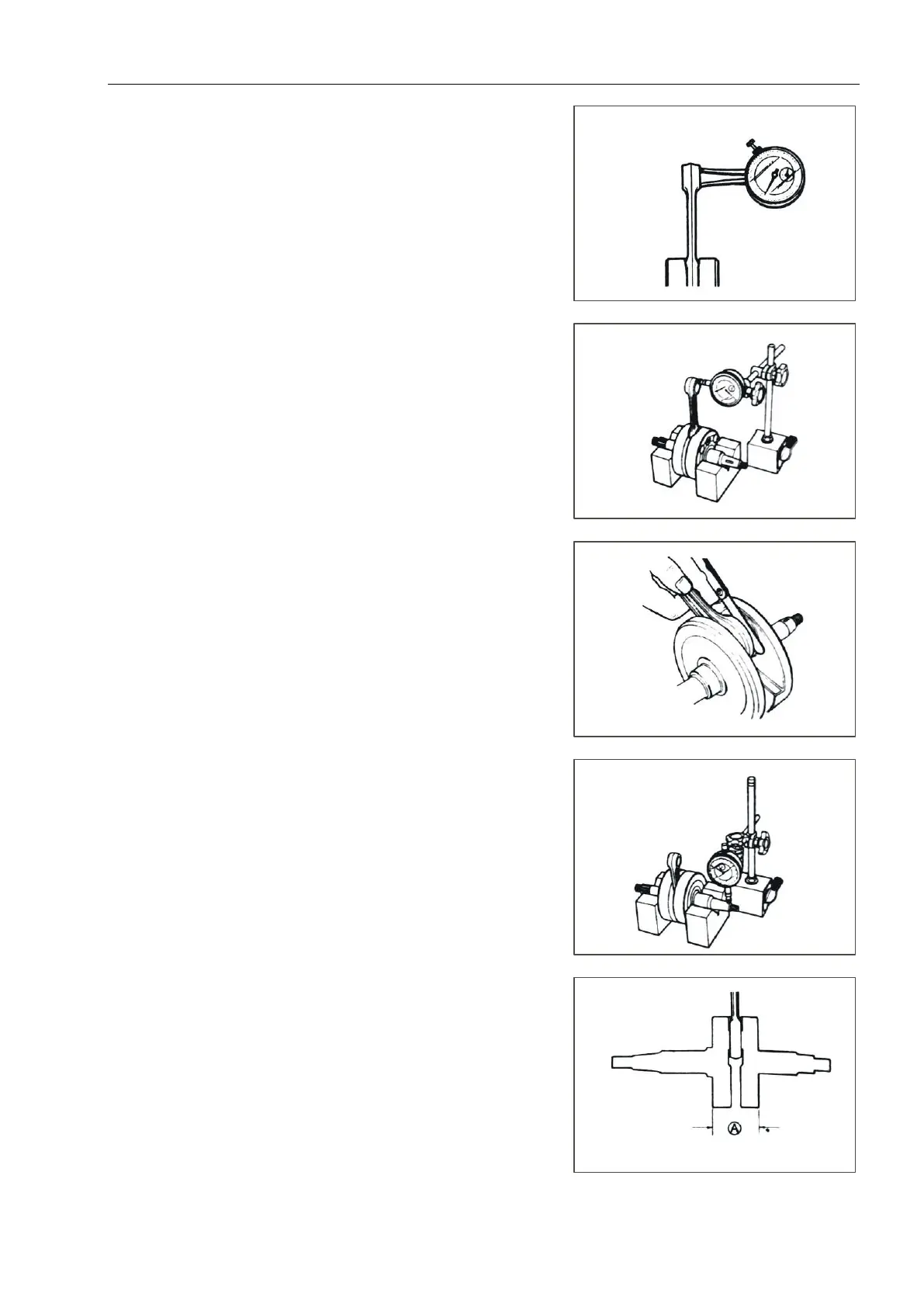

Deflection of connecting rod and big end backlash

of connecting rod

The wear of the large end of the connecting rod can be

determined by examining the movement of the small end of

the connecting rod.

The wear degree of the big end of the connecting rod

can also be checked by this method. As Fig. 3.4.63

Tools: magnetic rack Dial meter (1/100mm)

V-shaped block (100 mm) Limit of use: 1.2mm

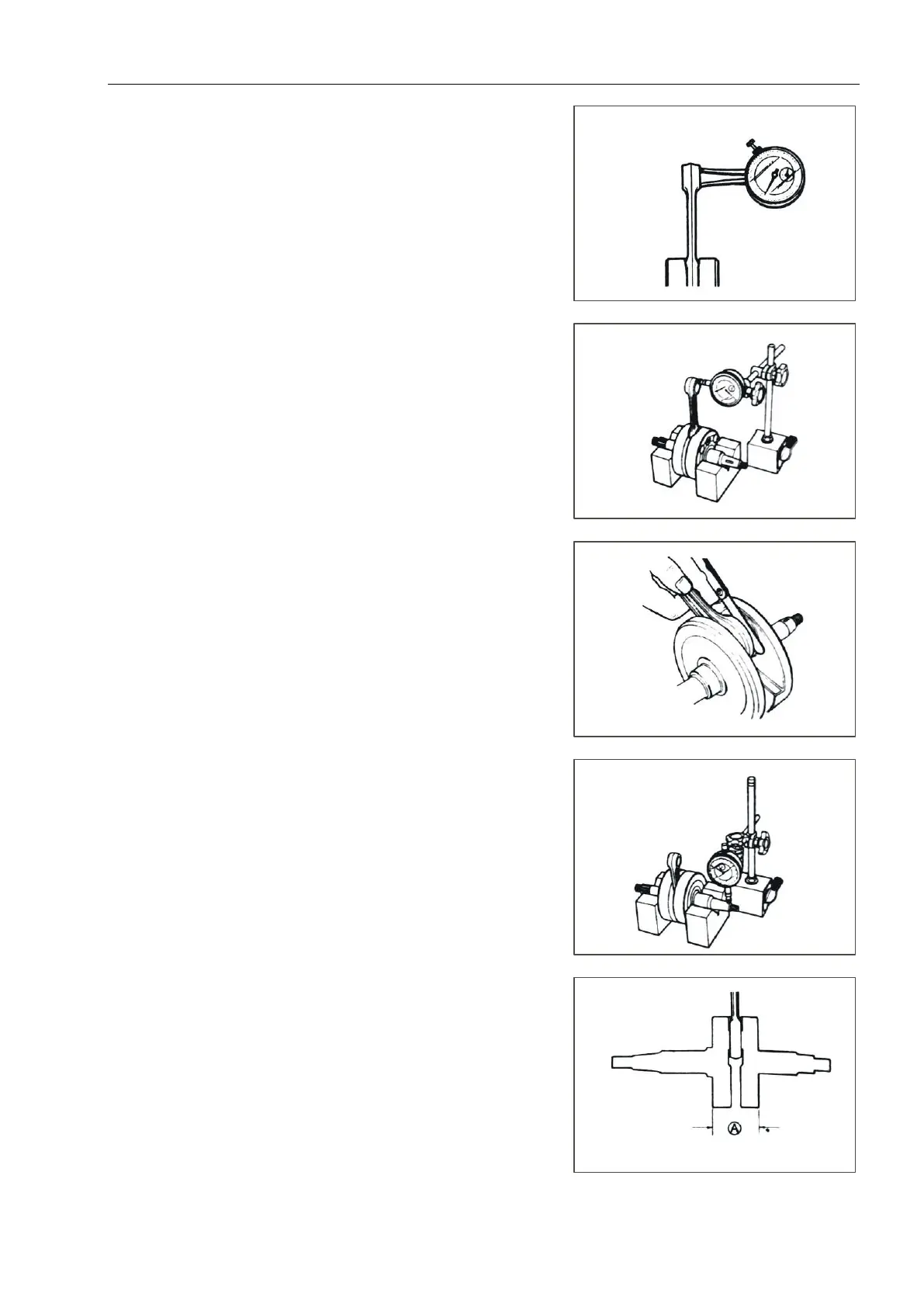

Push the large end of the connecting rod to one side

and measure the backlash using a feeler gauge. As in

Fig.3.4.64

Tools: feeler gauge Standard: 0.10 -- 0.45 mm

Limit of use: 1.0 mm

If the service limit is exceeded, the crankshaft

assembly may be replaced or the deflection and backlash

may be limited by replacing worn parts (e.g., connecting

rods, big-end bearings and crankshaft pins).

Crankshaft deflection

Support the crankshaft with a V-shaped block as

shown.Position the dial gauge and slowly turn the

crankshaft to read its yaw.

If the yaw is greater than the service limit, the

crankshaft should be corrected or replaced. As Fig. 3.4.65

Tools used; Magnetic rack

Dial meter (1/100mm) V-shaped block (100 mm)

Limit of use: 0.05mm

reassemble

When reassembling the crankshaft, the width between

arm A shall be within the standard range.

As Fig. 3.4.63

Standard crank width: 53.0 ± 0.1 mm

Fig.3.4.62

Fig.3.4.63

Fig.3.4.64

Fig.3.4.65

Fig.3.4.66

Loading...

Loading...