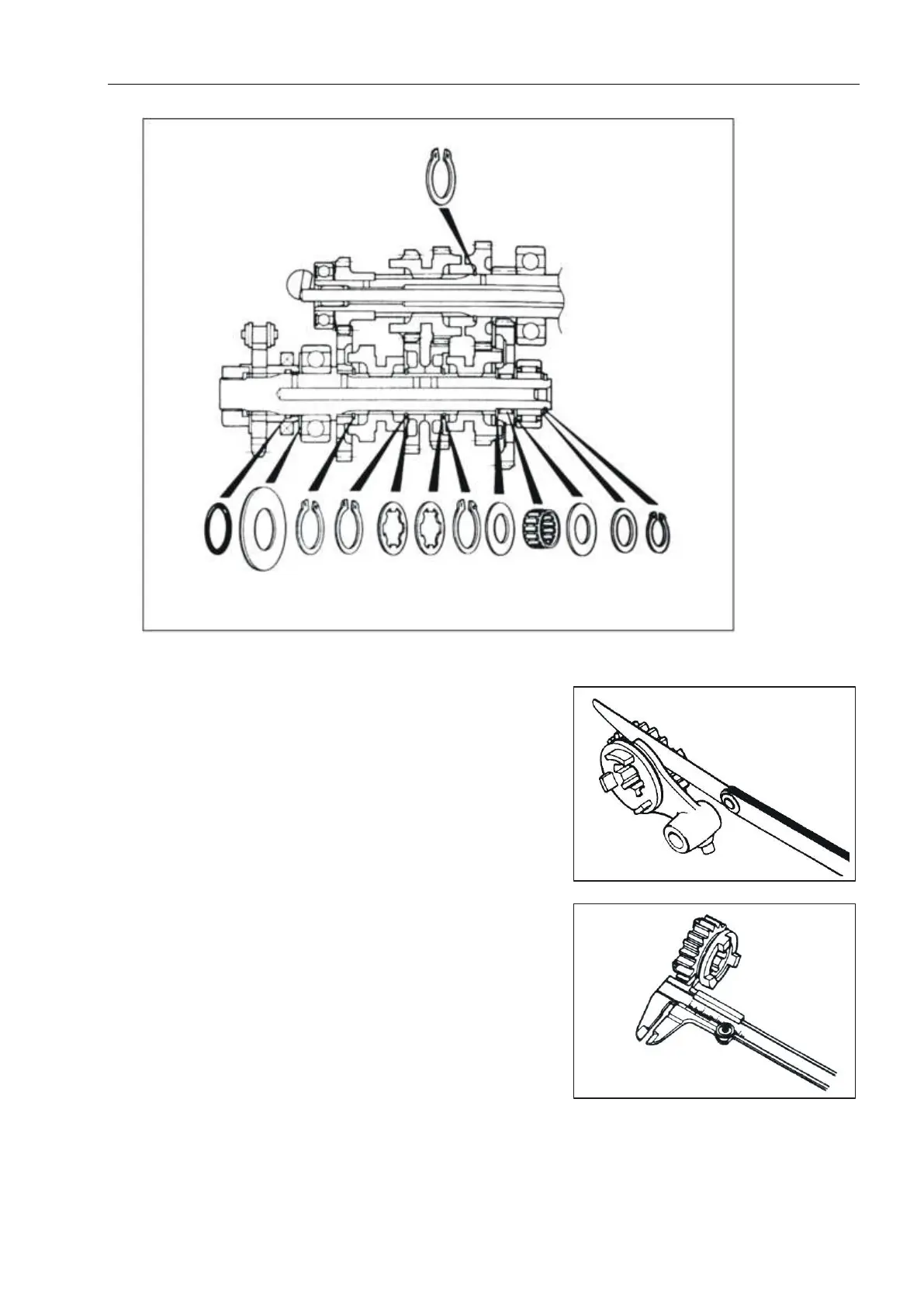

Chapter 3 Engine Section 4 Inspection and maintenance of engine componenets

3—39

Shift fork

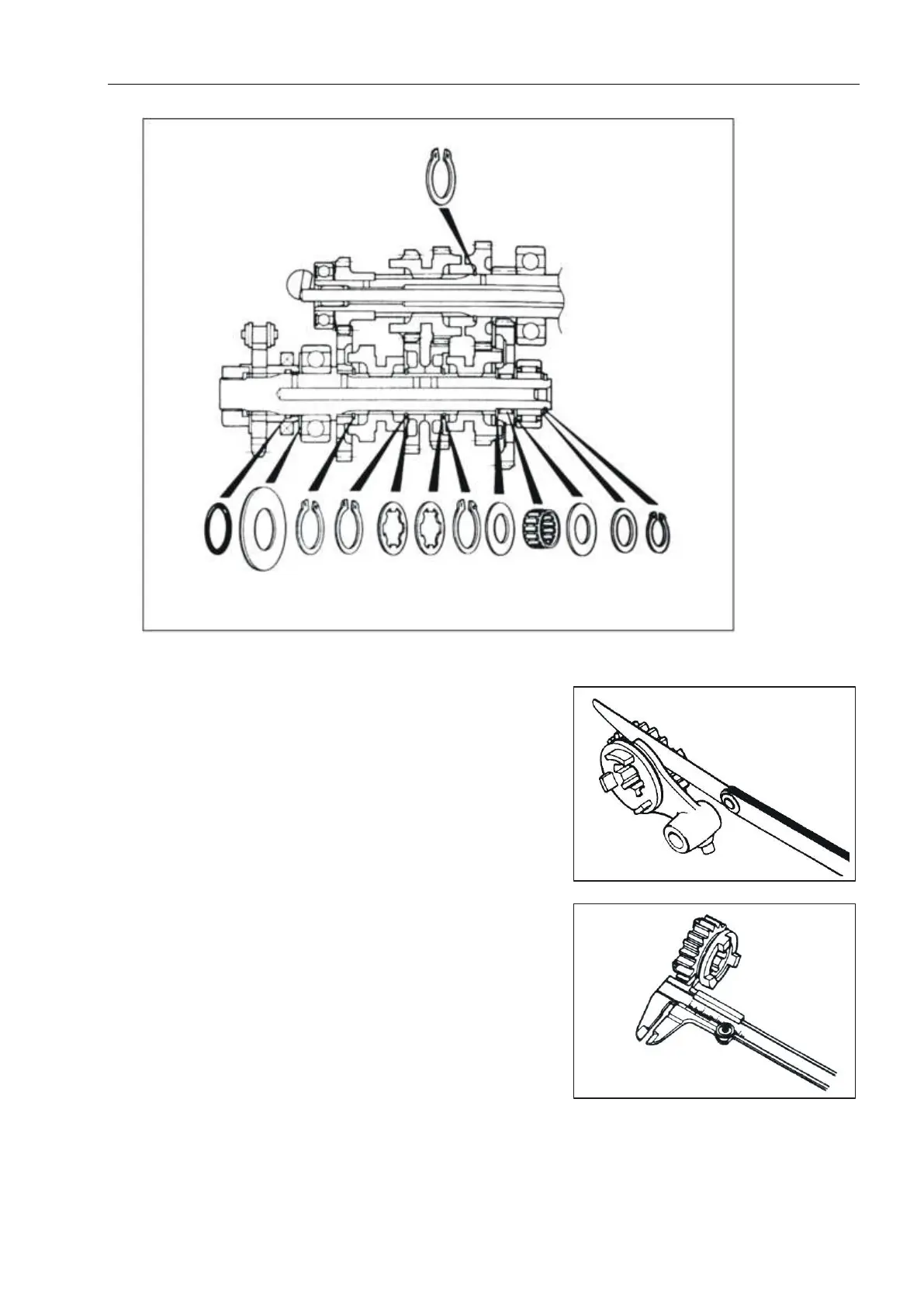

Use feeler gauge to measure the clearance of shift fork

in corresponding gear slot.

Each gap in the two shift forks plays an important role

in the smooth and reliable shift action.

Each fork has a fork and is arranged in a angular

groove of its gear.

During operation, there is a sliding contact between

the fork and the gear. When the shifting action is initiated,

the fork pushes the gear axially.

If the clearance is too large, the meshing gear can slip

away.As in Fig.3.4.77

If the clearance exceeds the specified, the fork,

corresponding gear, or both should be replaced.

Tools: feeler gauge

Limit of use: 0.50mm

Shift fork to slot clearance: 0.1-0.3

standard

Width of shifting fork slot

Shift forks and V-gear driven gears: 5.0 -- 5.1 mm

Driving gear of grade and grade : 5.5 ⅲ ⅳ -- 5.6 mm

As in Fig.3.4.78

Fig.3.4.77

Fig.3.4.78

Loading...

Loading...