136

3 MAJOR POSITIONING CONTROL

3.2 Setting the Positioning Data

■Setting method for the current value changing function

The following shows an example of a program and data setting to change the current value to a new value with the positioning

start signal. (The "[Md.20] Current feed value" value is changed to "5000.0 m" in the example shown.)

• Set the following data. (Set using the program referring to the start time chart.)

n: Axis No. - 1

*1 Refer to the following for details on the setting details.

Page 504 Control Data

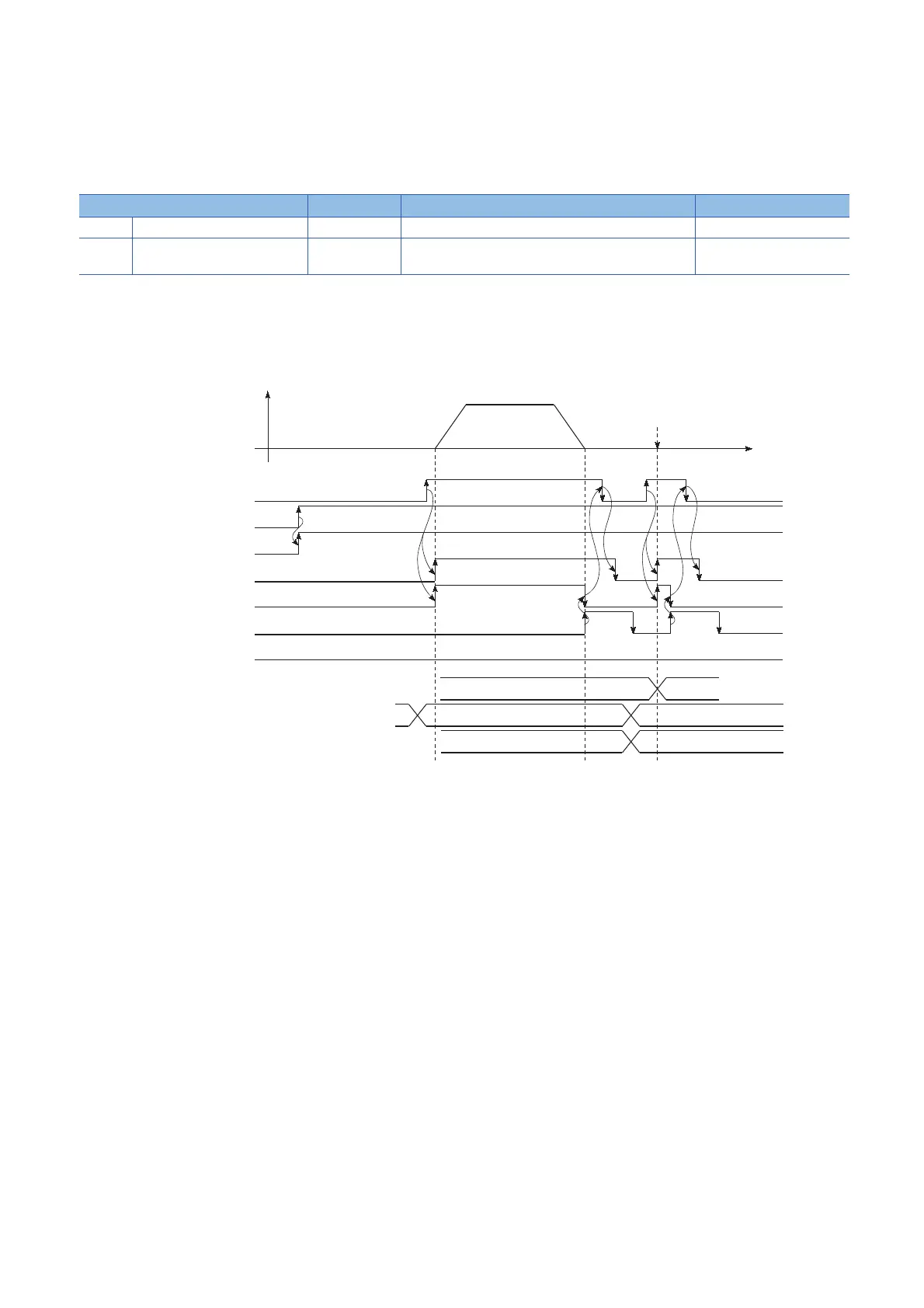

• The following shows a start time chart.

■RD77MS4 operation example

Setting item Setting value Setting details Buffer memory address

[Cd.3] Positioning start No. 9003 Set the start No. "9003" for the new current value. 4300+100n

[Cd.9] New current value 50000 Set the new "[Md.20] Current feed value". 4306+100n

4307+100n

Positioning start signal [Y10]

PLC READY signal [Y0]

READY signal [X0]

Start complete signal

([Md.31] Status: b14)

BUSY signal [X10]

Positioning complete signal

([Md.31] Status: b15)

[Cd.3] Positioning start No.

9003

V

t

Error detection signal

([Md.31] Status: b13)

[Md.20] Current feed value

50000

[Cd.9] New current value

Start of data No. 9003

Data No. during

positioning execution

Address during

positioning execution

50000

Loading...

Loading...