158

4 HIGH-LEVEL POSITIONING CONTROL

4.4 Setting the Condition Data

Condition data setting examples

The following shows the setting examples for "condition data".

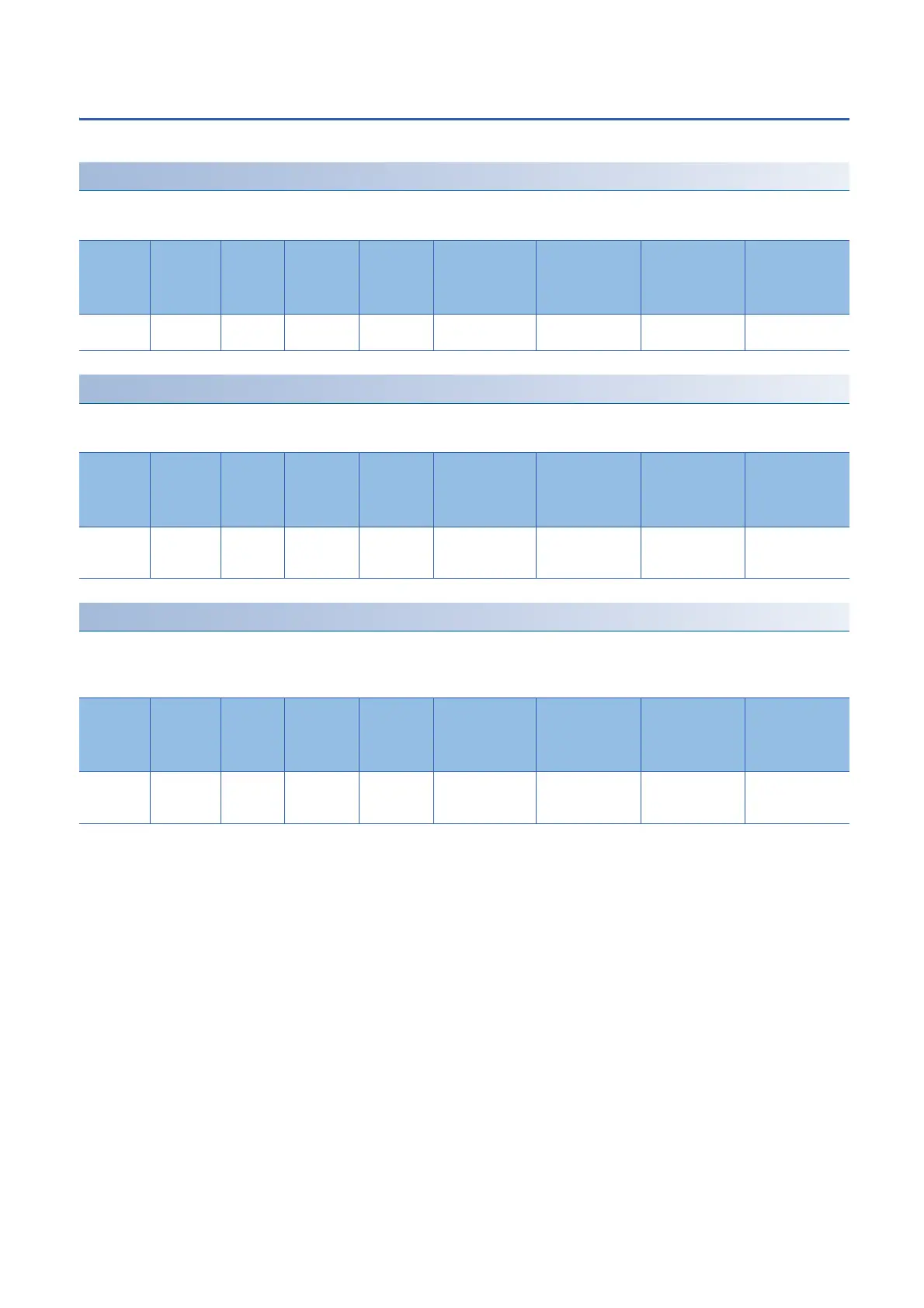

Setting the device ON/OFF as a condition

[Condition]

Device "X10" (Axis 1 BUSY signal) is OFF

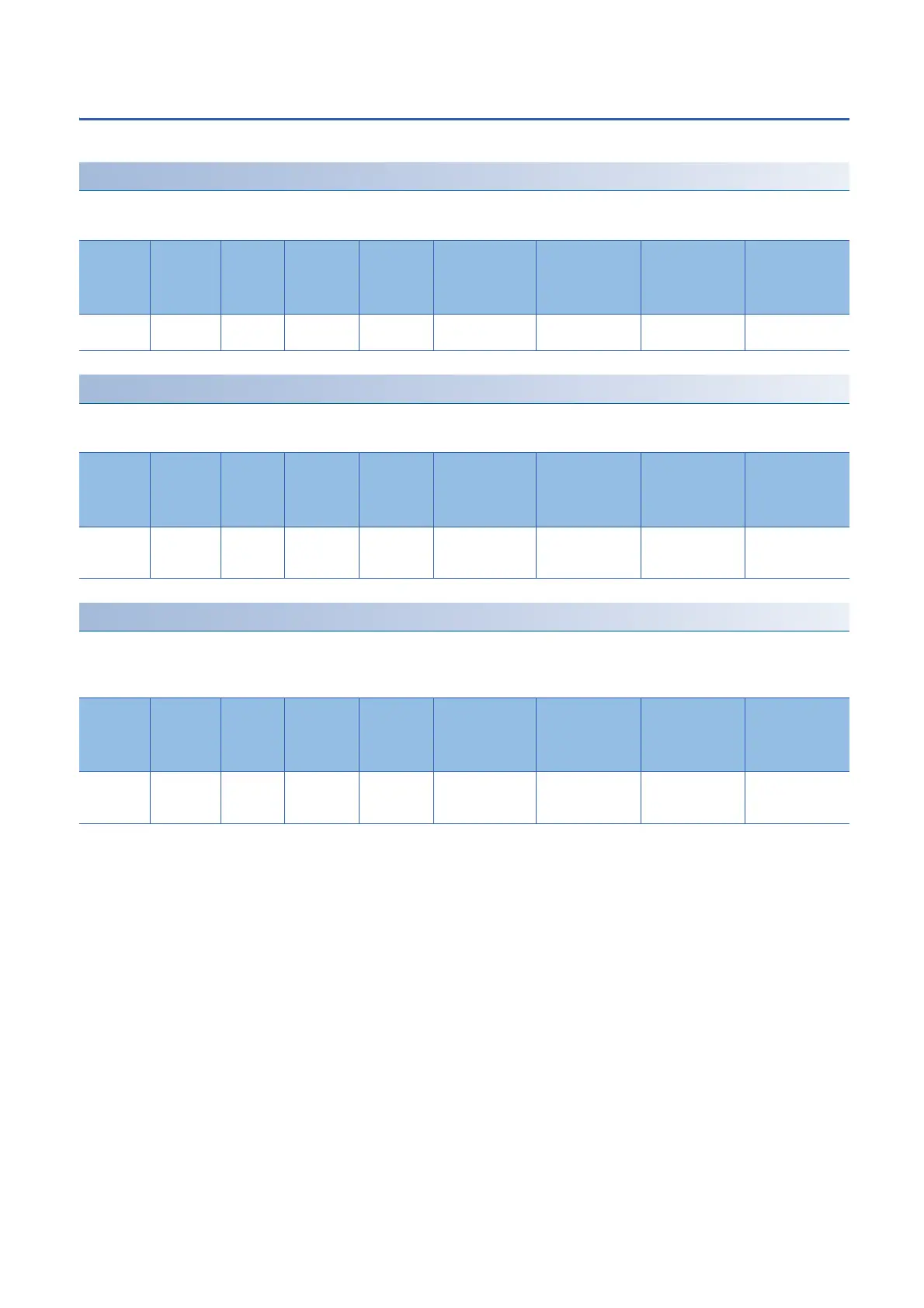

Setting the numeric value stored in the "buffer memory" as a condition

[Condition]

The value stored in buffer memory addresses "2400, 2401" ([Md.20] Current feed value) is "1000" or larger.

Designating the axis and positioning data No.

*1

*1 The axis and positioning data No. are to be simultaneously started in "simultaneous start".

[Condition]

Simultaneously starting "axis 2 positioning data No.3"

[Da.15]

Condition

target

[Da.16]

Condition

operator

[Da.17]

Address

[Da.18]

Parameter

1

[Da.19]

Parameter

2

[Da.23]

Number of

simultaneously

starting axes

[Da.24]

Simultaneously

starting axis

No.1

[Da.25]

Simultaneously

starting axis

No.2

[Da.26]

Simultaneously

starting axis

No.3

01H:

Device X

08H: DEV =

OFF

10H

[Da.15]

Condition

target

[Da.16]

Condition

operator

[Da.17]

Address

[Da.18]

Parameter

1

[Da.19]

Parameter

2

[Da.23]

Number of

simultaneously

starting axes

[Da.24]

Simultaneously

starting axis

No.1

[Da.25]

Simultaneously

starting axis

No.2

[Da.26]

Simultaneously

starting axis

No.3

04H: Buffer

memory (2

words)

04H: **

P1

2400 1000

[Da.15]

Condition

target

[Da.16]

Condition

operator

[Da.17]

Address

[Da.18]

Parameter

1

[Da.19]

Parameter

2

[Da.23]

Number of

simultaneously

starting axes

[Da.24]

Simultaneously

starting axis

No.1

[Da.25]

Simultaneously

starting axis

No.2

[Da.26]

Simultaneously

starting axis

No.3

05H:

Positioning

data No.

Low-order

16 bits

"0003H"

2H: 2 axes 1H: Axis 2 0H 0H

Loading...

Loading...