90

3 MAJOR POSITIONING CONTROL

3.2 Setting the Positioning Data

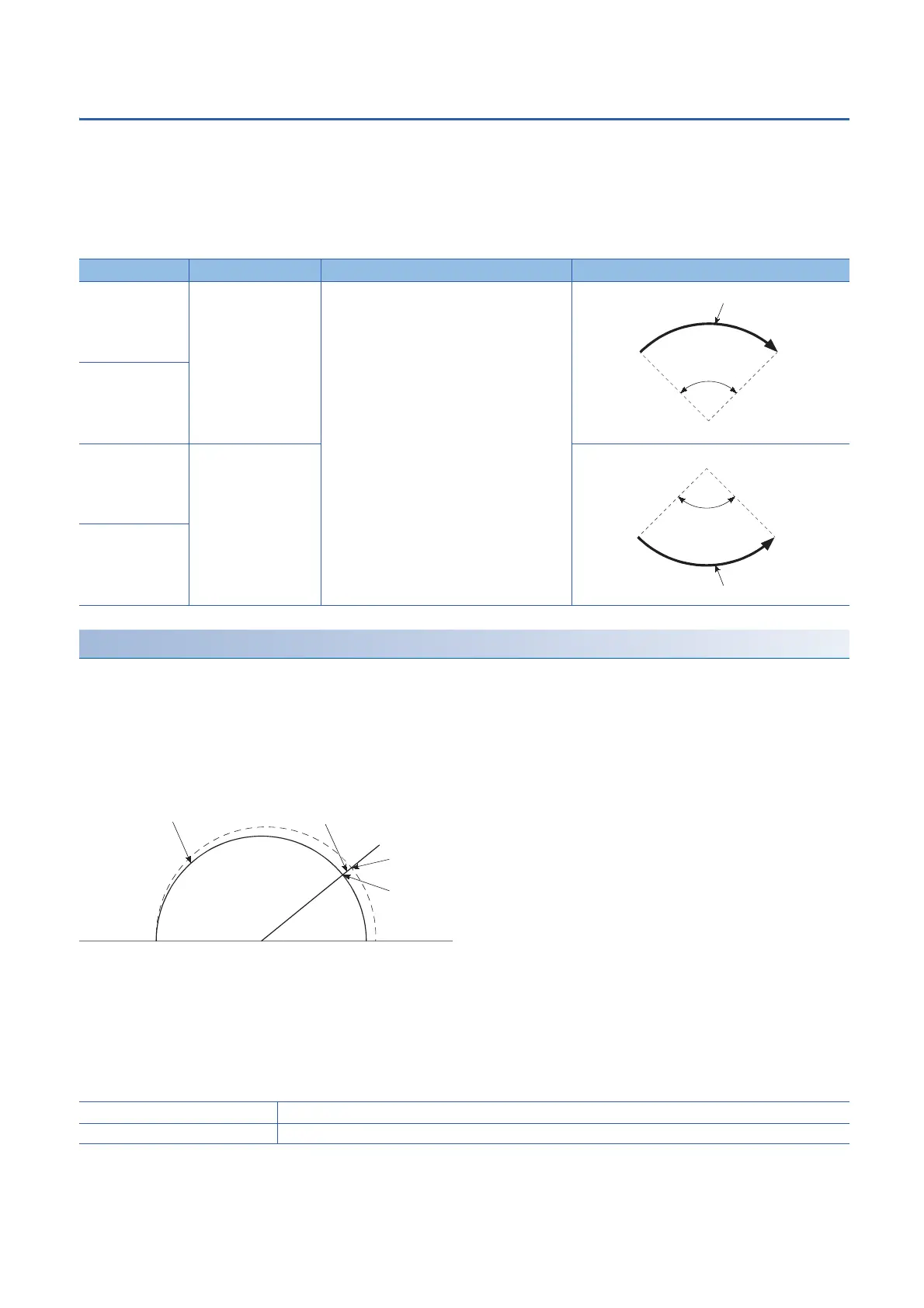

2-axis circular interpolation control with center point designation

In "2-axis circular interpolation control" ("[Da.2] Control method" = ABS circular right, INC circular right, ABS circular left, INC

circular left), two motors are used to carry out position control in an arc path having an arc address as a center point, while

carrying out interpolation for the axis directions set in each axis. (Refer to Page 64 Interpolation control for details on

interpolation control.)

The following table shows the rotation directions, arc center angles that can be controlled, and positioning paths for the

different control methods.

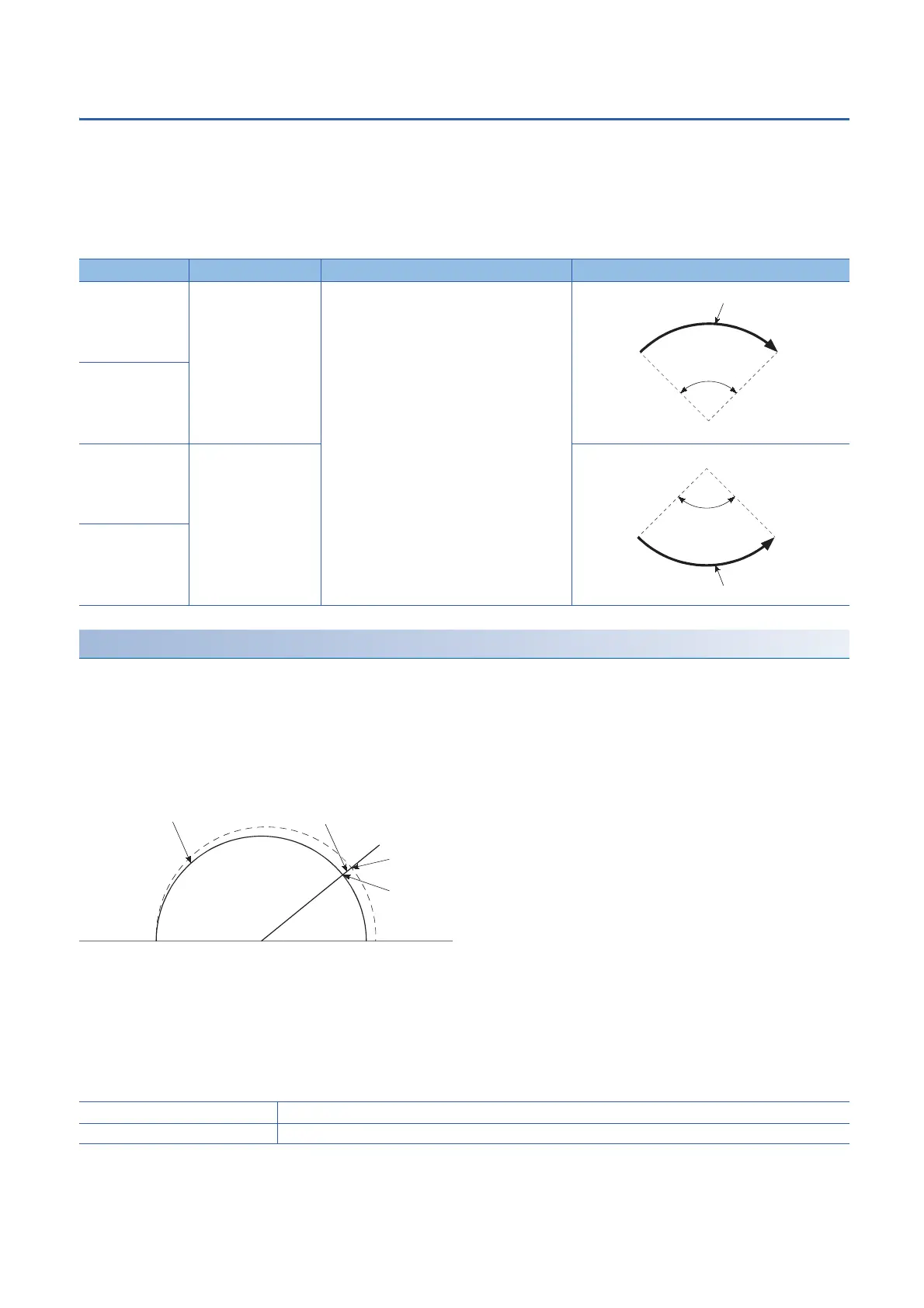

Circular interpolation error compensation

In circular interpolation control with center point designation, the arc path calculated from the start point address and center

point address may deviate from the position of the end point address set in "[Da.6] Positioning address/movement amount".

(Refer to Page 430 [Pr.41] Allowable circular interpolation error width.)

■Calculated error "[Pr.41] Allowable circular interpolation error width"

Circular interpolation control to the set end point address is carried out while the error compensation is carried out. (This is

called "spiral interpolation".)

In circular interpolation control with center point designation, an angular velocity is calculated on the assumption that

operation is carried out at a command speed on the arc using the radius calculated from the start point address and center

point address, and the radius is compensated in proportion to the angular velocity deviated from that at the start point.

Thus, when there is a difference (error) between a radius calculated from the start point address and center point address

(start point radius) and a radius calculated from the end point address and center point address (end point radius), the

composite speed differs from the command speed as follows.

■Calculated error > "[Pr.41] Allowable circular interpolation error width"

At the positioning start, the error "Large arc error deviation" (error code: 1A17H) will occur and the control will not start. The

machine will immediately stop if the error is detected during positioning control.

Control method Rotation direction Arc center angle that can be controlled Positioning path

ABS circular right Clockwise 0 < 360

INC circular right

ABS circular left Counterclockwise

INC circular left

Start point radius > End point radius As compared with the speed without error, the speed becomes slower as end point address is reached.

Start point radius < End point radius As compared with the speed without error, the speed becomes faster as end point address is reached.

Start point

(current stop

position)

End point

(positioning

address)

Positioning path

0

°

< θ

≤

360

°

Center point

Start point

(current stop

position)

End point

(positioning

address)

Center point

Positioning path

0

°

< θ

≤

360

°

Path using spiral interpolation

Center point address

Start point address

Error

Calculated end point address

End point address

Loading...

Loading...