4 HIGH-LEVEL POSITIONING CONTROL

4.5 Start Program for High-level Positioning Control

161

4

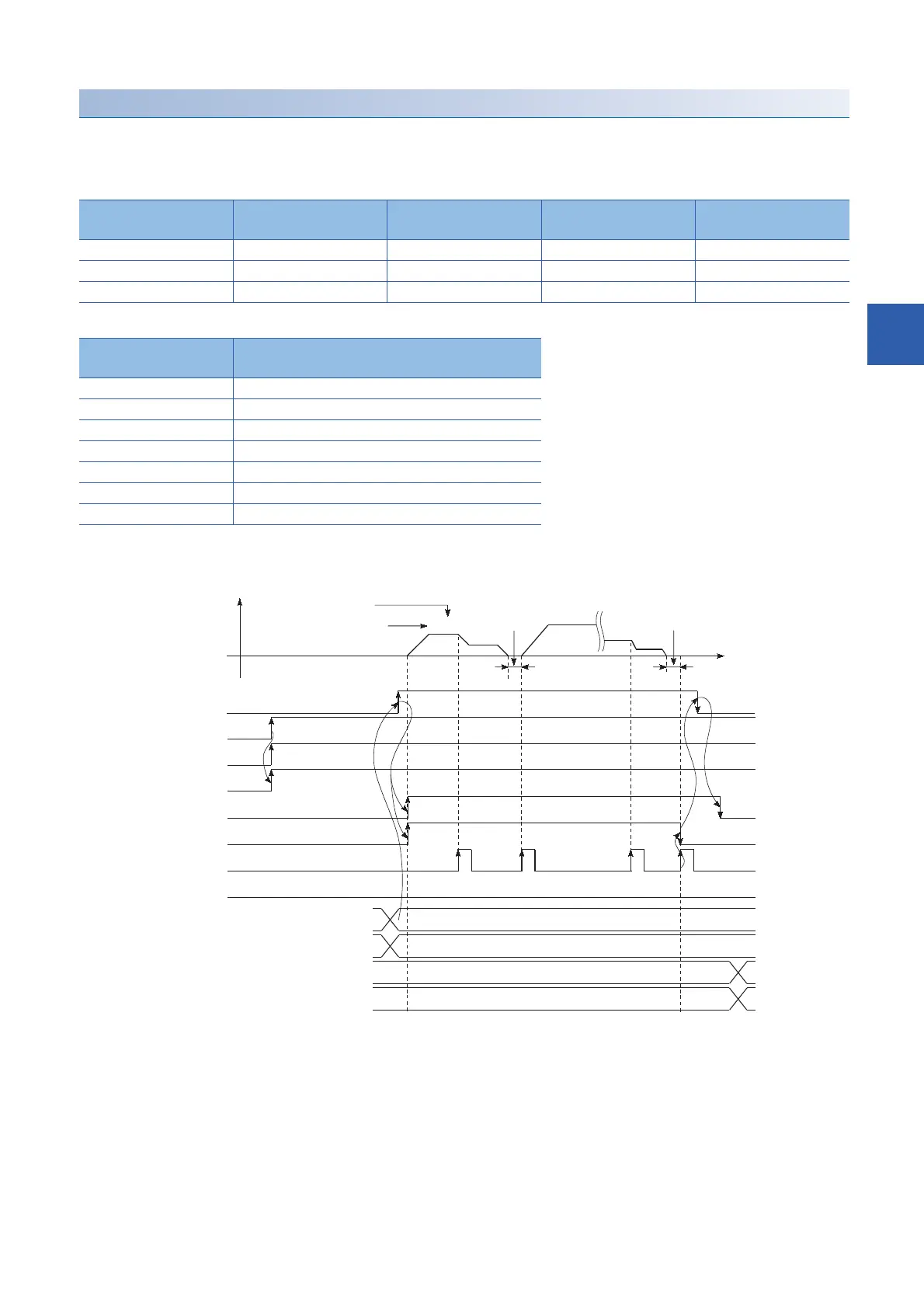

Start time chart

The following chart shows a time chart in which the positioning data No. 1, 2, 10, 11, and 12 of the axis 1 are continuously

executed as an example.

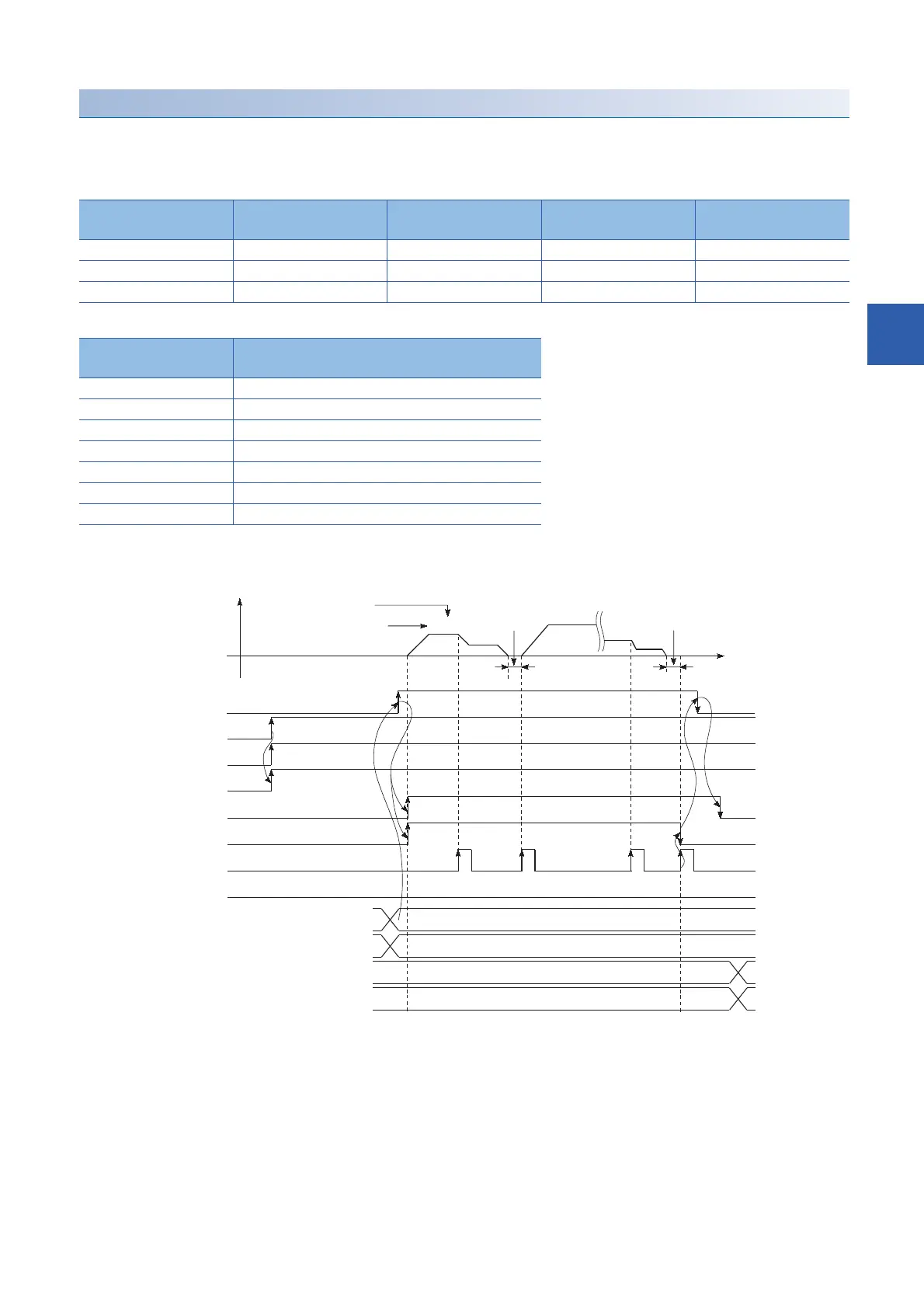

■Block start data setting example

■Positioning data setting example

■Start time chart

[RD77MS4 operation example]

Axis 1 block start data [Da.11] Shape [Da.12] Start data No. [Da.13] Special start

instruction

[Da.14] Parameter

1st point 1: Continue 1 0: Block start

2nd point 0: End 10 0: Block start

Axis 1 positioning data

No.

[Da.1] Operation pattern

1 11: Continuous path control

2 00: Positioning complete

10 11: Continuous path control

11 11: Continuous path control

12 00: Positioning complete

Positioning start signal [Y10]

All axis servo ON [Y1]

READY signal [X0]

Start complete signal

([Md.31] Status: b14)

BUSY signal [X10]

Positioning complete signal

([Md.31] Status: b15)

[Cd.3] Positioning start No.

V

t

Error detection signal

([Md.31] Status: b13)

[Cd.4] Positioning starting point No.

Positioning data No.

Dwell

time

12(00)

Operation pattern

1(11)

1st point

[buffer memory address 22000]

2nd point

[buffer memory address 22001]

11(11)

10(11)

2(00)

7000

1

-32767(8001H)

10(000AH)

PLC READY signal [Y0]

Dwell

time

Loading...

Loading...