8 - 2 8 - 2

MELSEC-Q

8 TROUBLESHOOTING

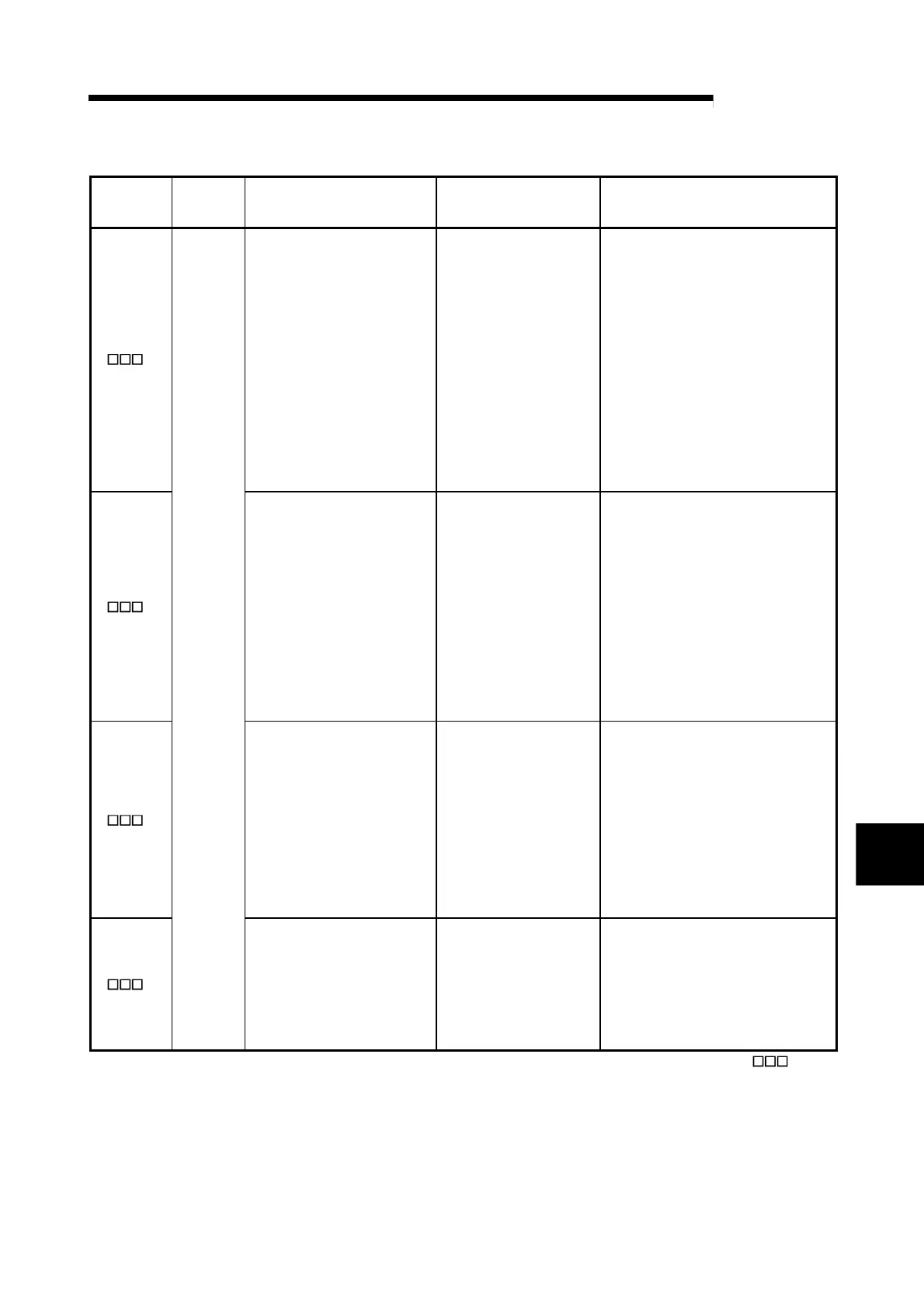

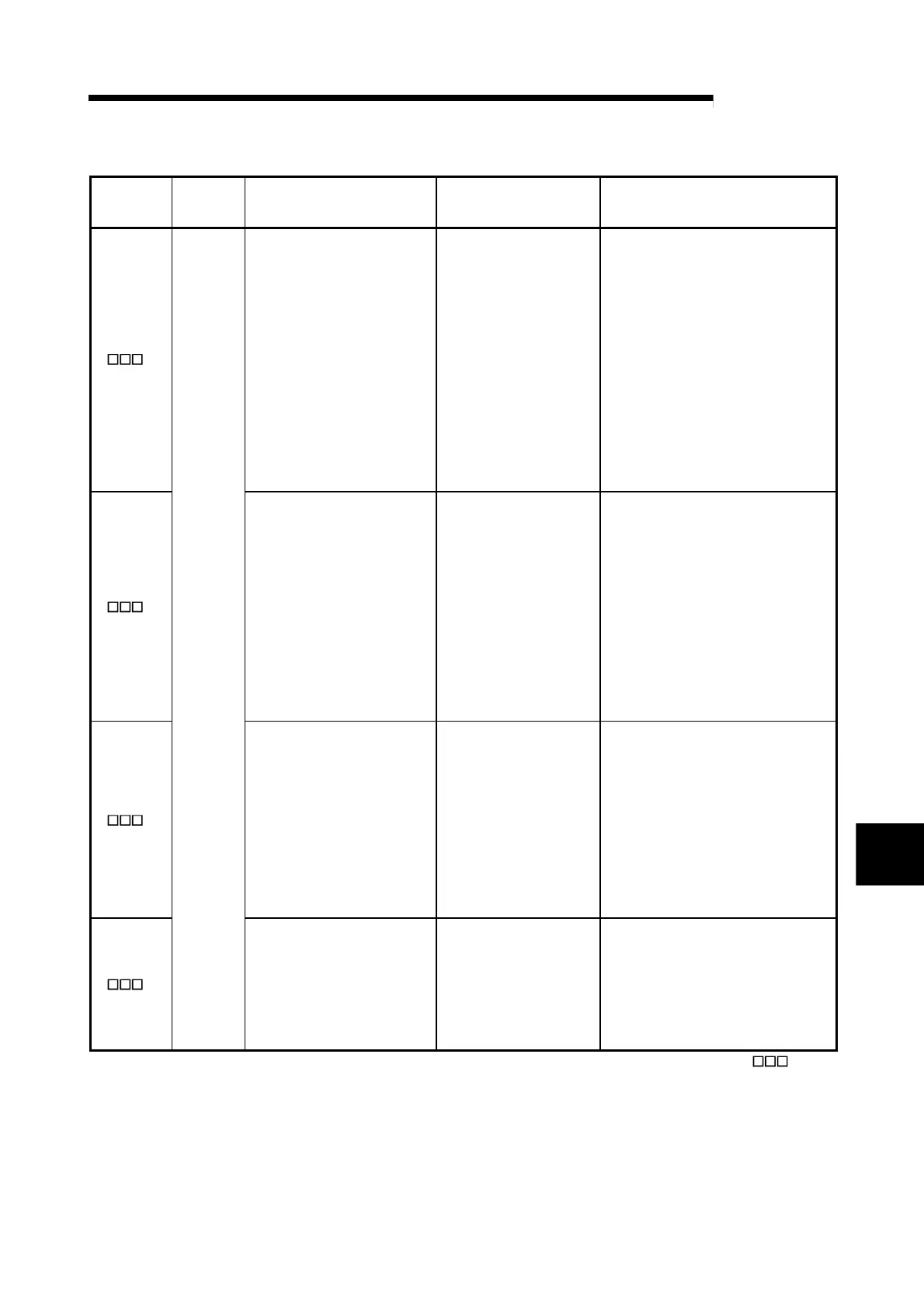

(2) Error Code List

Error code

(hexadecim

al)

*1

Error type Cause Error-time operation Corrective action

• Write to the area write-enabled

in the setting mode only was

performed in the operation

mode.

• Any of the following error codes

occurred during setting mode;

however, the mode is changed

to operation mode without

resetting the error.

3H

• Write data error to input range

(error code: 0204

H, 0404H)

• Write error to alert mode

setting (error code: 0C04

H,

0C14

H, 0C24H, 0C34H,

0D04

H, 0D14H, 0D24H,

0D34

H)

• The written data is held as

is.

• If data are written to

multiple write areas, the

smallest buffer memory

address among the ones

where data were

mistakenly written is stored

by priority.

• Make error rest in the following

procedure:

1) Choose the setting mode.

2) Set a correct value.

3) Make error reset.

• When changing from the operation mode

to the setting mode, make sure that the

PID continuation flag (buffer memory

address: 169) is 0 (STOP), and turn off

the setting/operation mode command

(Yn1).

4H

• Data outside the setting range

was written.

• The written data is held as

is.

• When write area setting is

over the upper and lower

limit values, the upper and

lower limit values are used

to exercise the control.

• If multiple data outside the

setting range were written,

the smallest buffer memory

address among the ones

where data were

mistakenly written is stored

by priority.

• Set data within the range.

5H

• The setting of the upper/lower

output limiter or upper/lower

setting limiter is illegal.

• The written data is held as

is.

• The upper and lower limit

values that may be set are

used to exercise control.

• If data are written to

multiple limiter setting area,

the smallest buffer memory

address among the ones

where data were

mistakenly written is stored

by priority.

• Make setting so that the upper limit value

is greater than the lower limit value.

6H

Write data

error

• The set value was changed

during default setting

registration.

• The written data is ignored.

• Any set value cannot be

changed until error reset is

made.

• If another write error

occurs, error code (the

buffer memory address: 0)

data does not change.

• After making error reset command (Yn2:

ON), change the set value.

*1 The buffer memory address occurring write data error is displayed at " " in

hexadecimal.

Example) "0234

H" expresses that data out of the range are written to proportional

band (P) setting (buffer memory address: 35 (23

H)).

8

Loading...

Loading...