3 - 28 3 - 28

MELSEC-Q

3 SPECIFICATIONS

(c) Zone PID data

The zone PID data divides input range into 8 zones by zone upper limit setting,

and then sets the PID constants and control response parameters used for each

zone.

Zone dividing is performed by the upper limit setting (refer to the table on the next

page for buffer memory) of zone 1 to 8.

Selecting the PID constants and control response parameters used in each

segment is performed by the zone PID data No. (refer to the table on the previous

page for buffer memory).

There are following three types for selecting the method.

1) When selecting optionally the PID constants and control response parameters

Set 1 to 8 to the zone PID data No. for each segment.

The Q62HLC performs the control using the PID constants and control

response parameter of zone 1 to 8.

2) When selecting automatically the PID constants and control response

parameters

The zone PID data No. is set to 0.

The Q62HLC performs the control after automatically selecting the zone

including the set value of segment in execution.

If the characteristics of control target differ depending on the zone, the control

performance can be improved being compared with the case where a single

PID constant is used for controlling.

3) When controlling with the PID constants and control response parameters

Zone 1 upper limit is set as input range upper limit, and 0 is set to zone PID

data No. of each segment.

The Q62HLC performs the control using the PID constants and control

response parameter of zone 1.

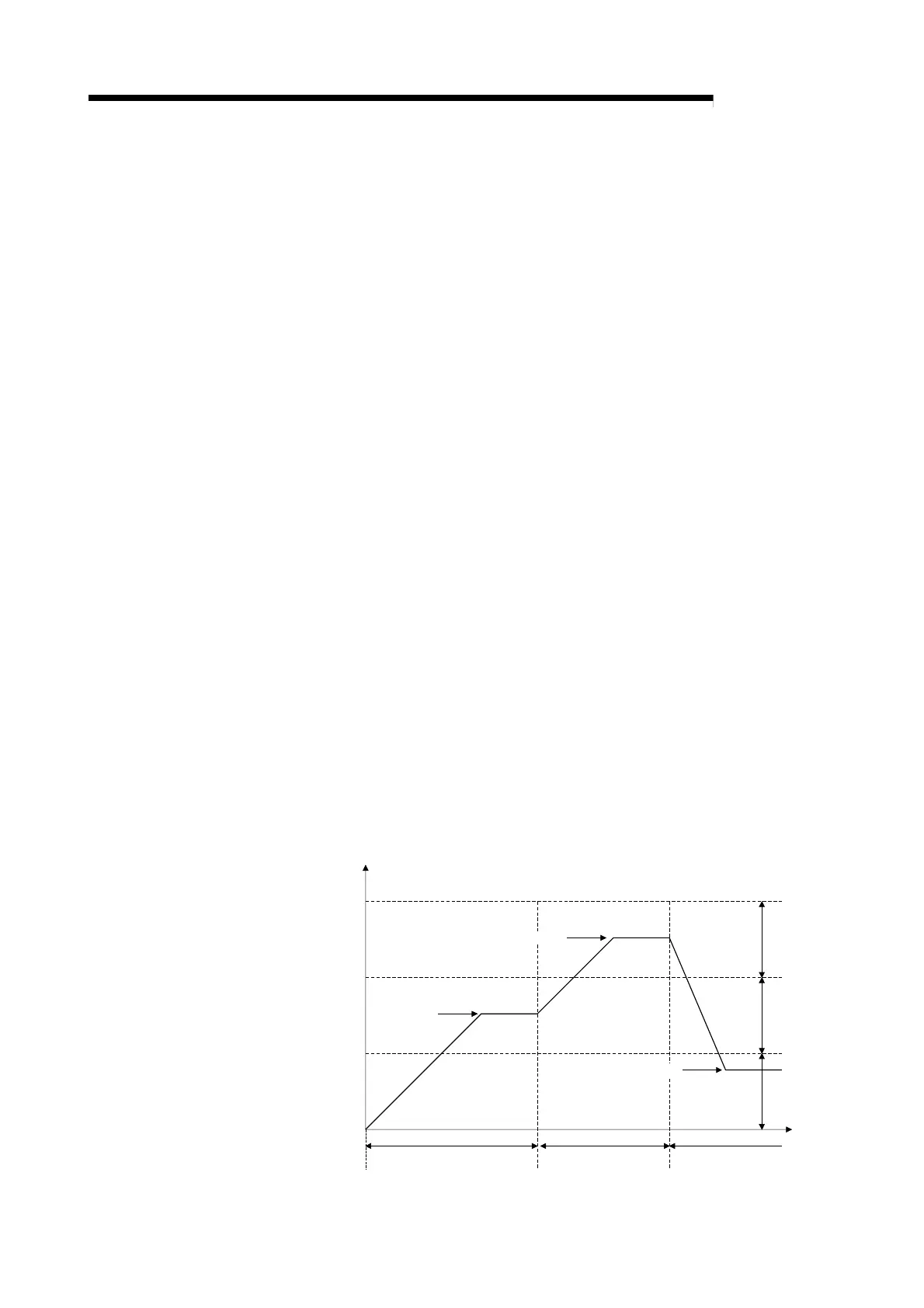

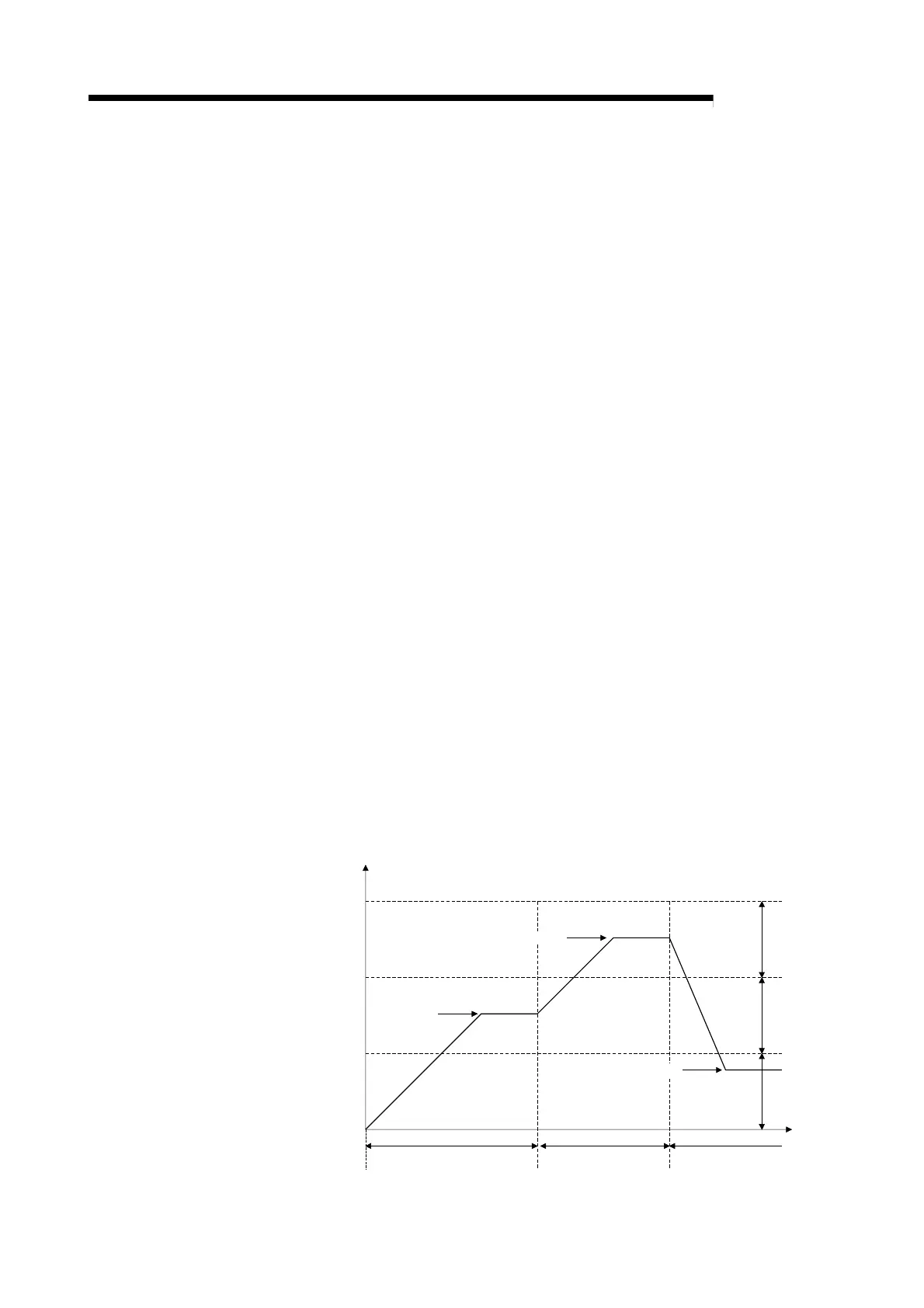

Example) When dividing the input range into 3 zones and when setting 2 for the

PID data setting of the execution zone (For buffer memory addresses,

check the following table) in the segment 1 and 2, setting 3 for the PID

data setting of the execution zone in the segment 3 and 4, setting 1 for

the PID data setting of the execution zone in the segment 5 and 6

Set value

Time

Zone 3

Zone 2

Zone 1

Set value B

Set value C

Set value A

Zone 3 upper limit

Zone 2 upper limit

Zone 1 upper limit

(Input range upper limit)

It is controlled by the PID

constant of zone 2.

It is controlled by

the PID constant

of zone 3.

It is controlled by

the PID constant

of zone 1.

Loading...

Loading...