© Munters AB, 2020 77

11.4

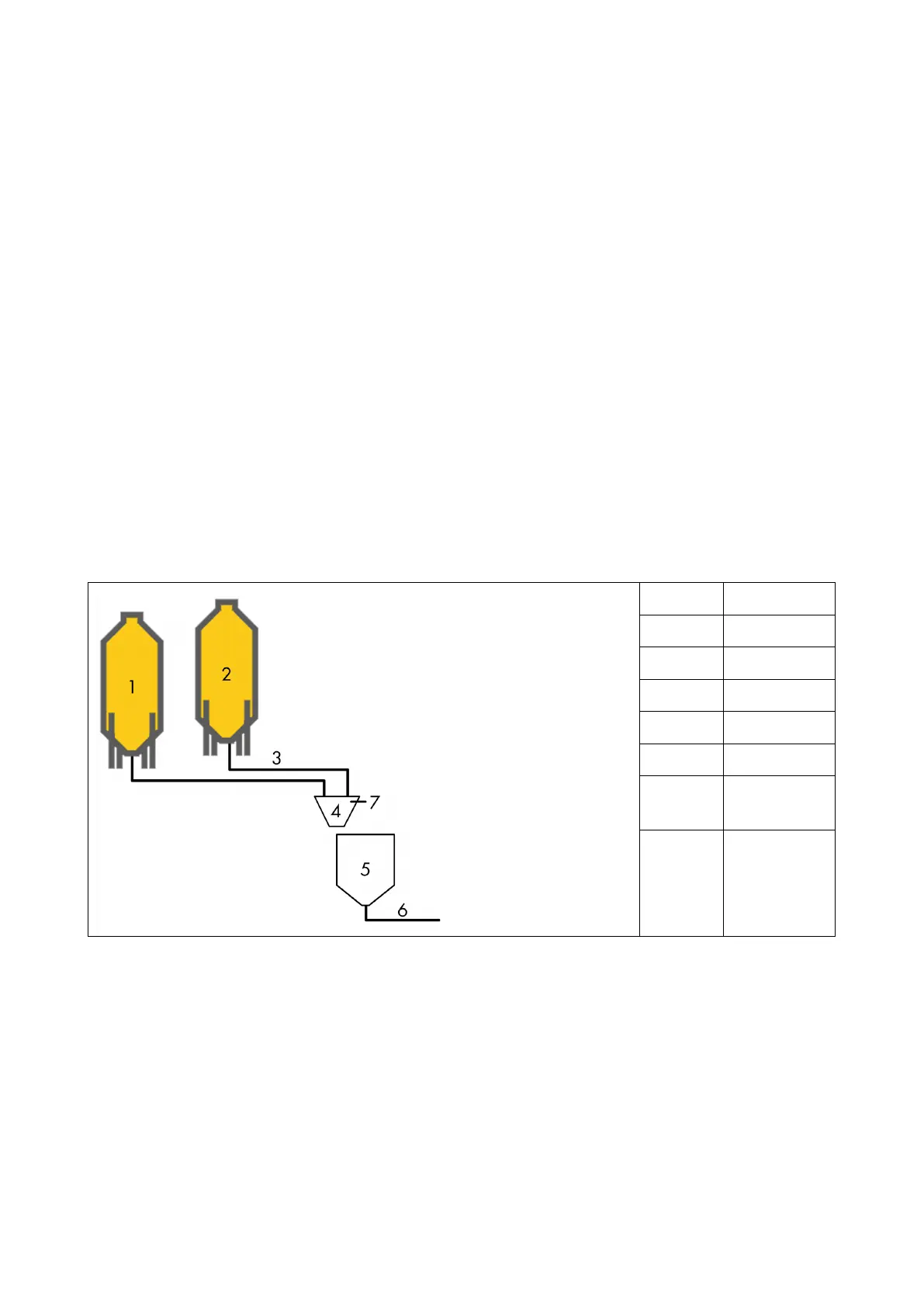

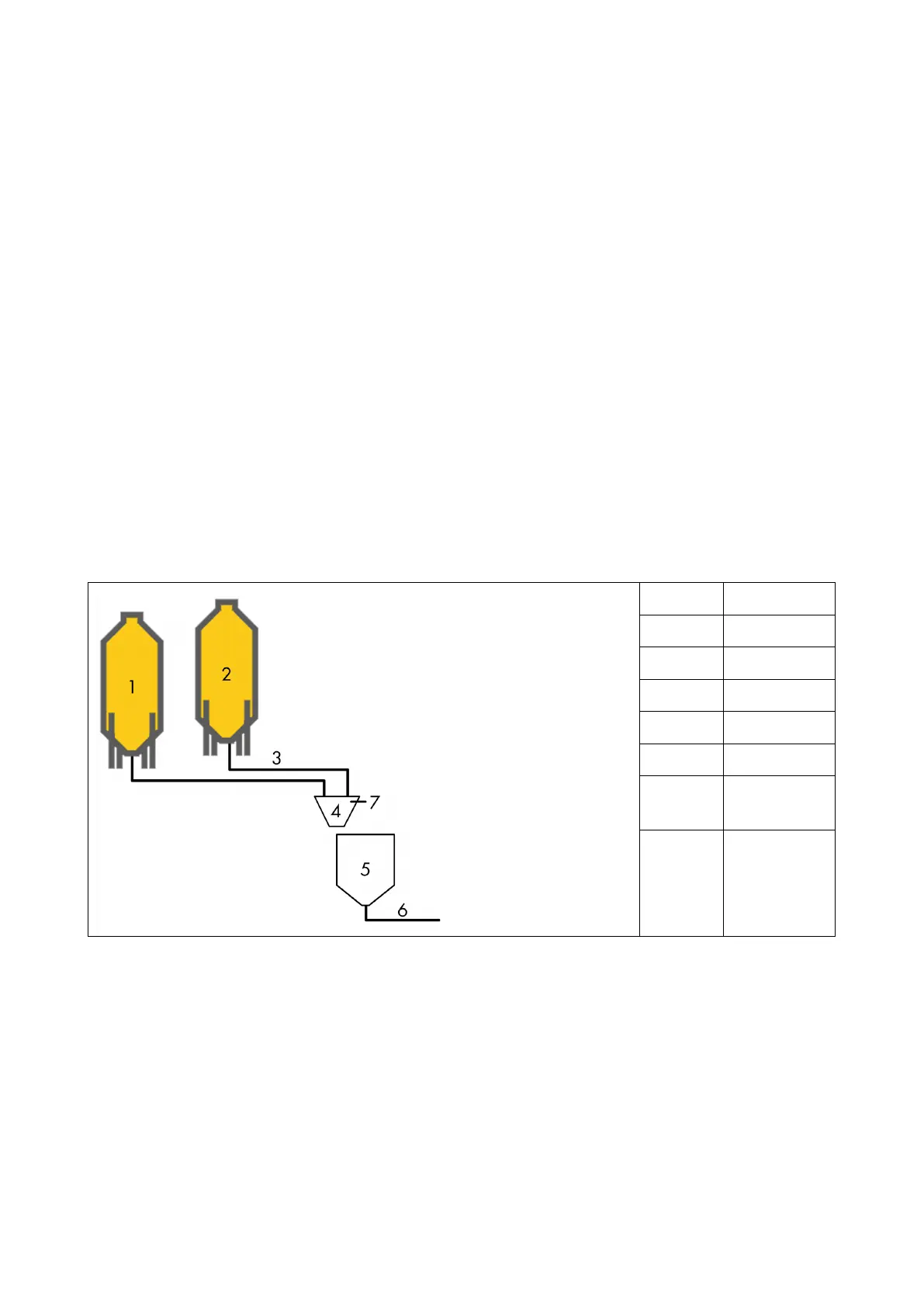

Batch Weighing System

The Trio Batch Weighing System enables mixing different feeds stored in two or three silos

and distributing the feed mixture to hoppers (Figure 2).

Trio supports two types of weighers:

•

External batch weighers, in which defined quantities of feed are added to the mix.

Each batch generates a pulse, which is transmitted to the Trio via the digital input

channel (refer to External Batch Bin Installation, page 77).

•

Electronic batch weighers, which use a load cell system to measure the feed

delivered on each batch. Trio receives the data via the scale card. The user defines

the batch size (weight) and the feed mixture (in percentages). This data determines

how much feed each silo provides to each batch (refer to Electronic Batch

Weighing Installation, page 79).

This system does not require silo load cells to provide data on feed distribution. However,

when there are multiple systems in place, Trio automatically prioritizes the data input as

follows:

•

Batch weighers

•

Silo

•

Cross auger (time)

Number Name

3 Silo Augers

4 Batch Bin

Auger

Hopper

Limit

sensor

Figure 2: Batch Weighing System

11.4.1

E

XTERNAL

B

ATCH

B

IN

I

NSTALLATION

Map and define cross augers (refer to Error! Reference source not found., page Error!

Bookmark not defined.).

Every time feed is placed into the batch weigher, Trio receives a pulse. Each pulse

corresponds to a quantity of feed. The mix is generated by defining the quantities

(meaning, the number of pulses) of different type of feed to be added.

Connect the batch counter to a digital input port.

Loading...

Loading...