© Munters AB, 2020 75

Auger overtime alarm: The augers operate when the hoppers switch

transmits a signal to distribute feed. The augers cease operating when

hoppers are full. If the run time exceeds the user defined run time, the

auger active sensor (refer to Devices and Sensors) should generate an

alarm.

Auger under-time alarm: Under time alarms occur when the auger

motor has been off for longer than the under time parameter.

Feeder overtime alarm: Feeders begin receiving feed when the last

pan sends a signal. Feed distribution continues until the pans are full. If

the feed distribution is longer than the user-defined time, the feeder

active sensor should generate an alarm.

Feeder under time: Feeder under time defines the time required to

generate an alarm when the feeder is not active.

o

Stop feeding System: If enabled, the controller stops the feeding cycle once a

cross over runtime is detected.

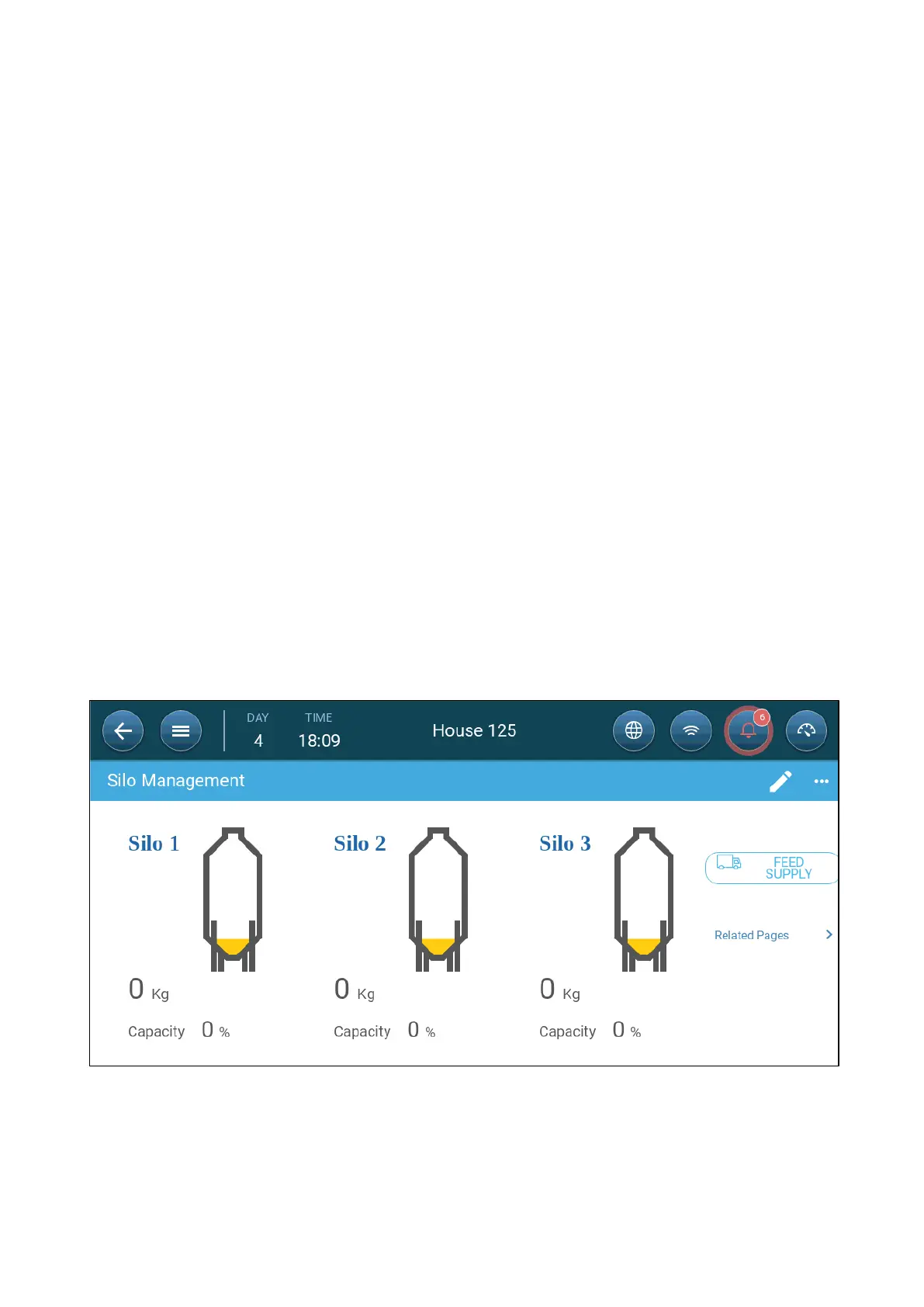

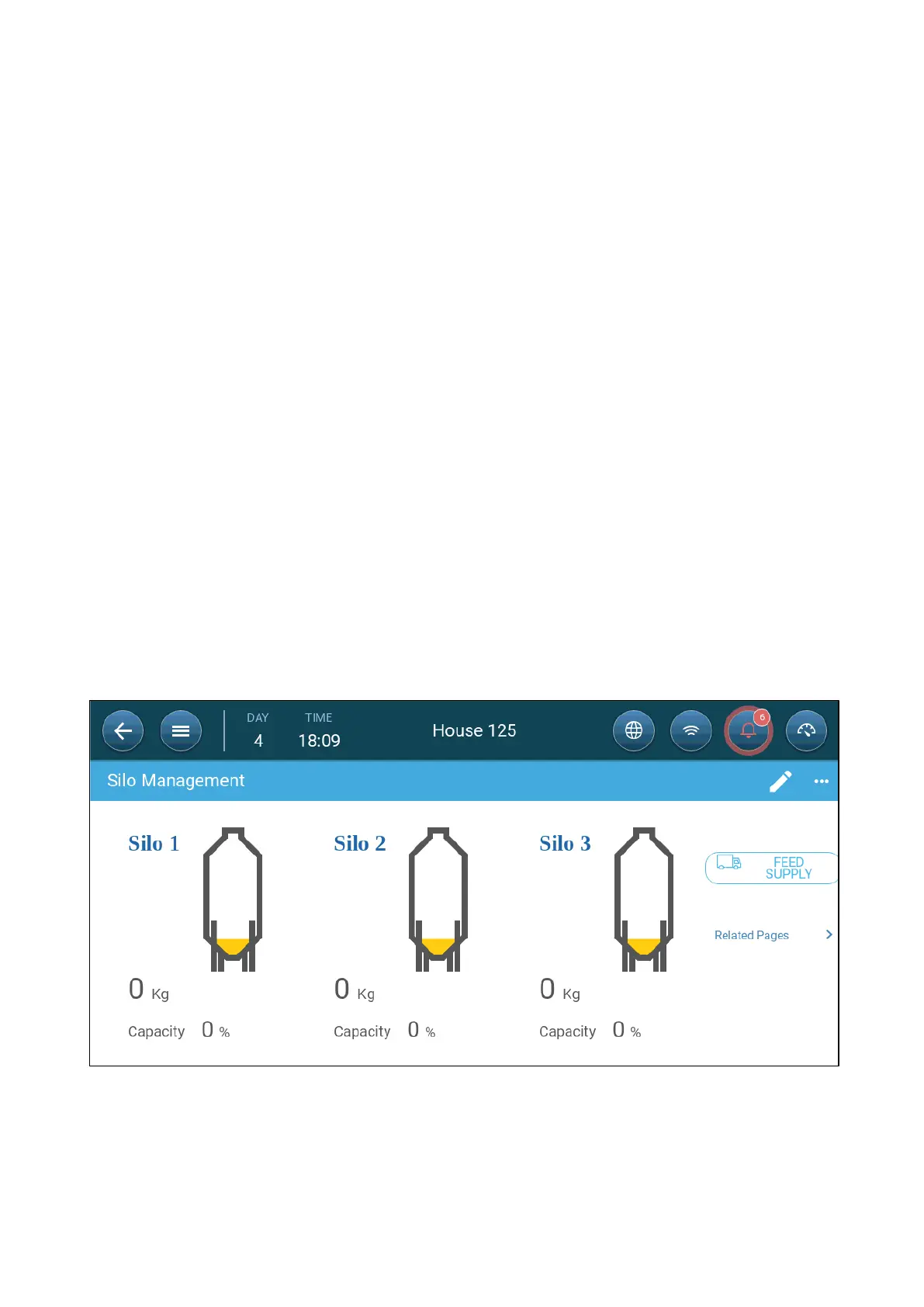

11.3

Configuring the Silo

Silo content is determined by weight using load cells attached to the silo legs.

•

Silo weight increases when feed is delivered

•

Silo weight decreases when feed is distributed to birds

1. Go to Flock > Silo Management.

The screen displays the amount of feed remaining in each silo, in quantity and

percentage of the total capacity.

2. Enter the amount of feed in each silo. Range: 0 – 50000 kgs.

3. To specify the feed type, click Feed Supply. Click Feed Type and select the type.

Loading...

Loading...