7-13

7-2 Realtime Autotuning

7

Adjustment Functions

The settings for the following parameters are automatically set and cannot be changed. (The

settings will not change even if realtime autotuning is executed.)

Note 1. Parameters that are automatically set cannot be changed if realtime autotuning is enabled.

Note 2. Pn31 is 10 when position control is used and the Realtime Autotuning Mode Selection

(Pn21) is set to 1 to 6. Otherwise, it is 0.

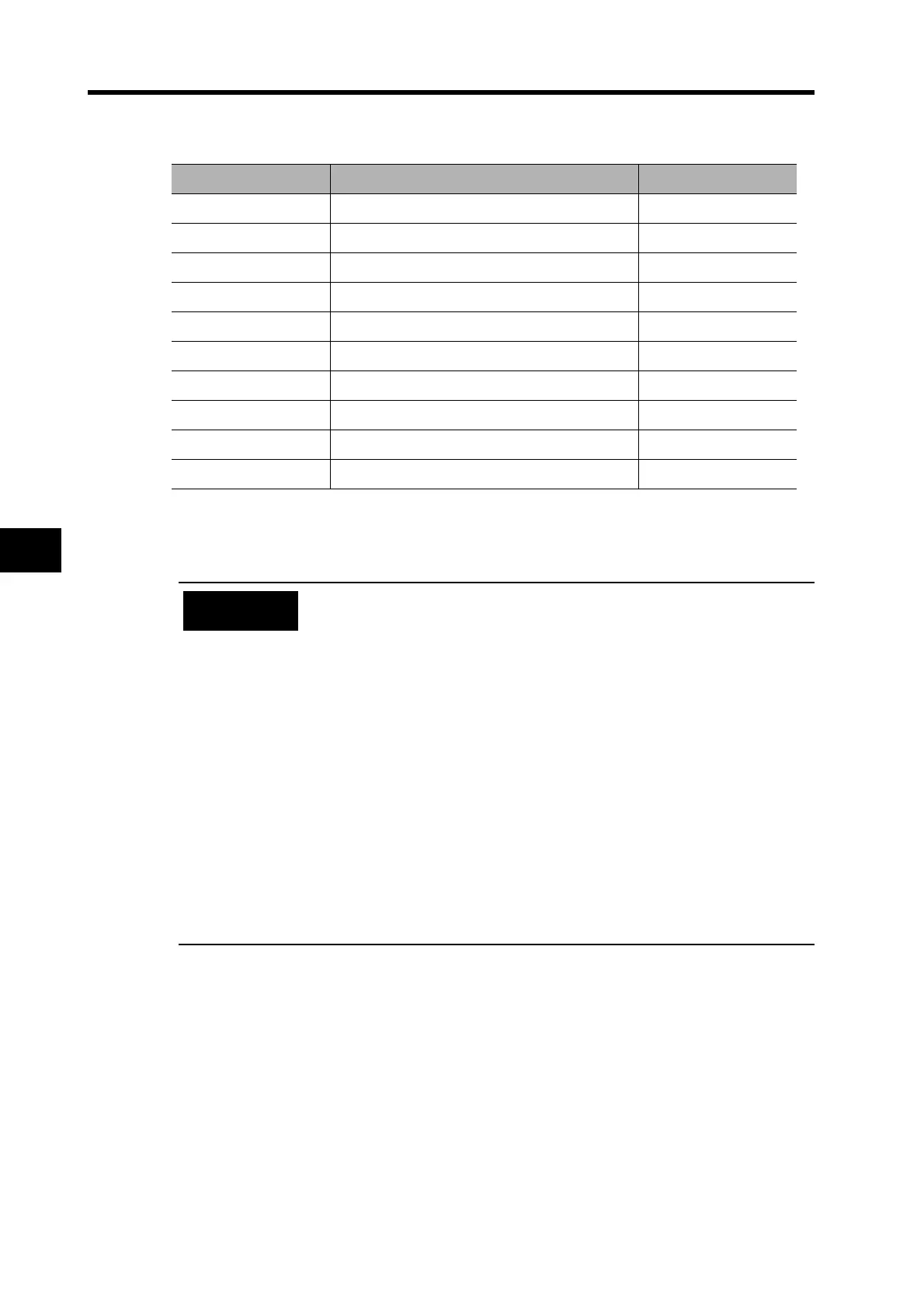

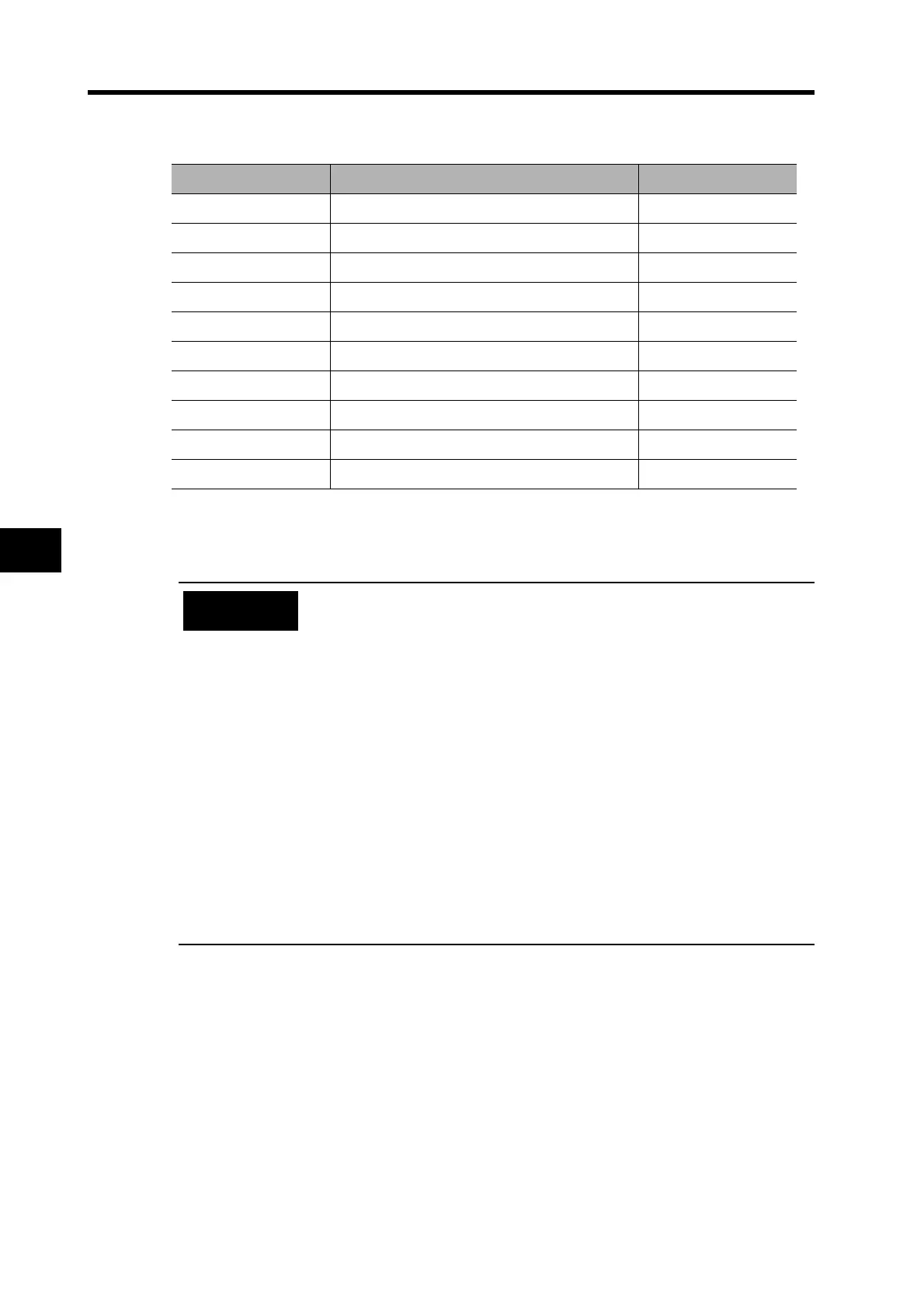

Parameter No. Parameter name Set value

Pn15 Feed-forward Amount 300

Pn16 Feed-forward Command Filter 50

Pn27 Instantaneous Speed Observer Setting 0

Pn30 Gain Switching Input Operating Mode Selection 1

Pn31 Control Gain Switch 1 Setting 10

Pn32 Gain Switch 1 Time 30

Pn33 Gain Switch 1 Level Setting 50

Pn34 Gain Switch 1 Hysteresis Setting 33

Pn35 Position Loop Gain Switching Time 20

Pn36 Control Gain Switch 2 Setting 0

• Unusual noise or vibration may occur until the load inertia is estimated or

the adaptive filter stabilizes after startup, immediately after the first servo

turns ON, or when the Realtime Autotuning Machine Rigidity Selection

(Pn22) is increased. This is not a problem if it disappears right away. If the

unusual noise or vibration, however, continues for three or more

reciprocating operations, take the following measures in any order you

can.

• Write the parameters used during normal operation to the EEPROM.

• Lower the Realtime Autotuning Machine Rigidity Selection (Pn22).

• Manually set the notch filter.

• Once unusual noise or vibration occurs, the Inertia Ratio (Pn20) may have

changed to an extreme value. In this case, also take the measures

described above.

• Out of the results of realtime autotuning, the Inertia Ratio (Pn20) is

automatically saved to the EEPROM every 30 minutes. Realtime

autotuning will use this saved data as the default value when the power is

turned OFF and turned ON again.

• The Instantaneous Speed Observer Setting (Pn27) will automatically be

disabled (0) if realtime autotuning is enabled.

Precautions

for Correct Use

Loading...

Loading...