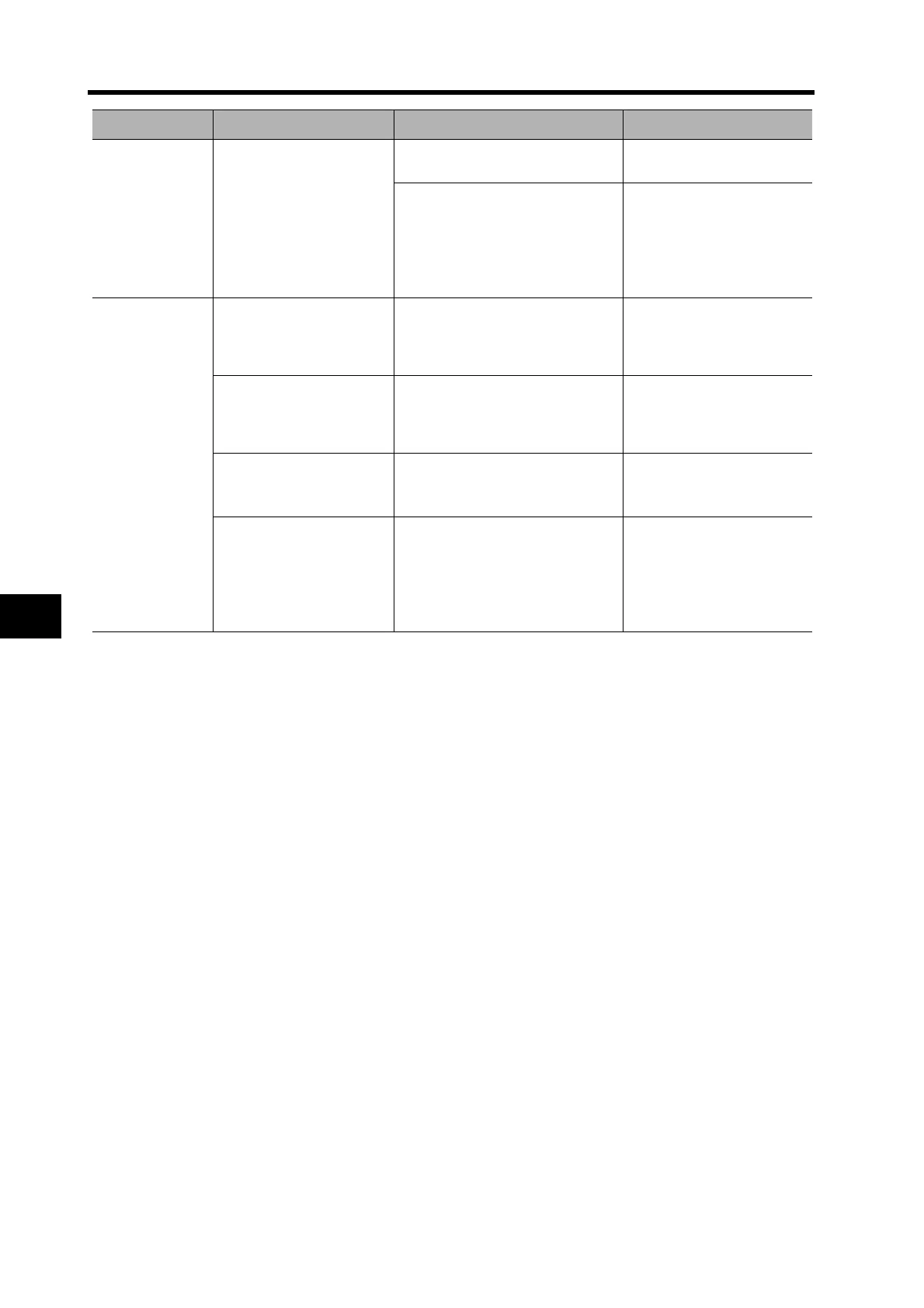

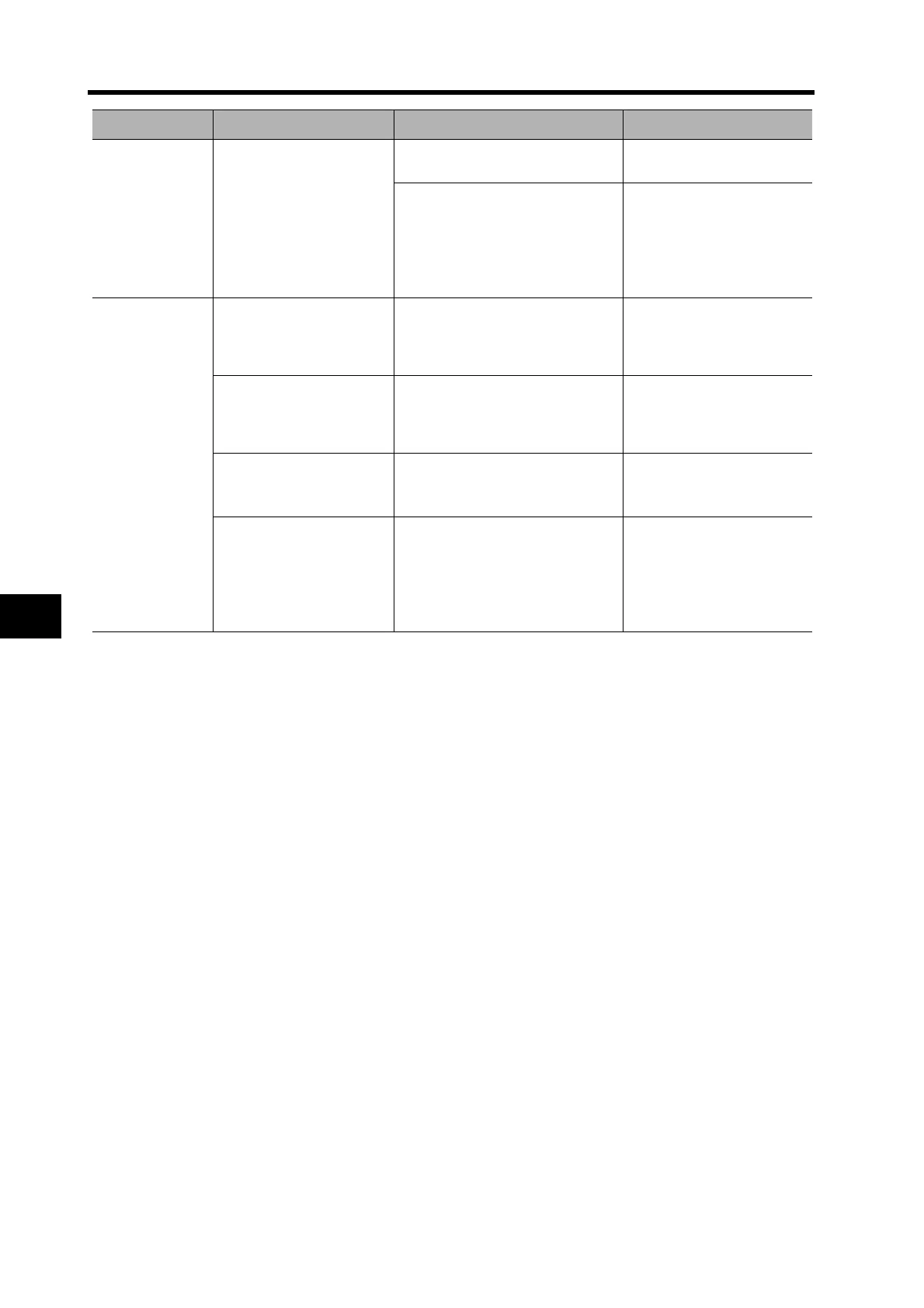

8-19

8-3 Troubleshooting

8

Troubleshooting

Vibration is

occurring at the

same frequency

as the power

supply.

Inductive noise is

occurring.

Check whether the Servo Drive

control signal lines are too long.

Shorten the control signal

lines.

Check to see whether control signal

lines and power supply lines are

bundled together.

• Separate control signal

lines from power supply

lines.

• Use a low-impedance

power supply for control

signals.

The position is

misaligned.

(Position

misalignment

occurs without an

alarm being

output.)

There is an error in the

coupling of the mechanical

system and the Servomo-

tor.

Check whether the coupling of the

mechanical system and the Servo-

motor is misaligned.

Correct the coupling

between the mechanical

system and the Servomotor.

Noise is entering the Devia-

tion Counter Reset Input

(ECRST).

Check whether the control signal

lines and power supply lines are

bundled together.

Separate the control signal

lines from the power supply

lines or take other measures

against noise.

The gain is wrong. ---

• Perform normal mode

autotuning.

• Perform manual tuning.

The load inertia is too large.

Check the following:

• Check whether the load is too

large.

• Check whether the rotation

speed of the Servomotor is too

high.

• Adjust the gain.

• Review the load condi-

tions, and replace the

Servomotor and Servo

Drive with appropriate

models.

Symptom Probable cause Items to check Countermeasures

Loading...

Loading...