11-6

11-3 Alarms

OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type)

11

Error and Maintenance

11-3 Alarms

If the Servo Drive detects an error, it outputs an alarm (ALM), turns off the power drive circuit,

and displays the error number on the front panel.

Precautions for Correct Use

Refer to "Error Diagnosis Using the Alarm Displays" (P.11-14) for appropriate alarm measures.

Reset the alarm using one of the following methods. Remove the cause of the alarm first.

• Turn OFF the power supply, then turn it ON again.

• Reset the alarm via MECHATROLINK-II communications or on CX-Drive.

However, some alarms can only be reset by turning the power supply OFF then ON again. Refer

to the "Alarm List" (P.11-6).

If you reset an alarm while the operation command (RUN) is turned ON, the Servo Drive starts

operation as soon as the alarm is released, which is dangerous. Be sure to turn OFF the RUN

before clearing the alarm.

If the RUN is always ON, first check safety sufficiently before clearing the alarm.

The Overload (Alarm No.16) cannot be reset for 10 seconds once it occurs.

Any displays such as hh, , and HH on the error number mean internal malfunction on the MPU.

Cut off the power immediately when you encounter such a case.

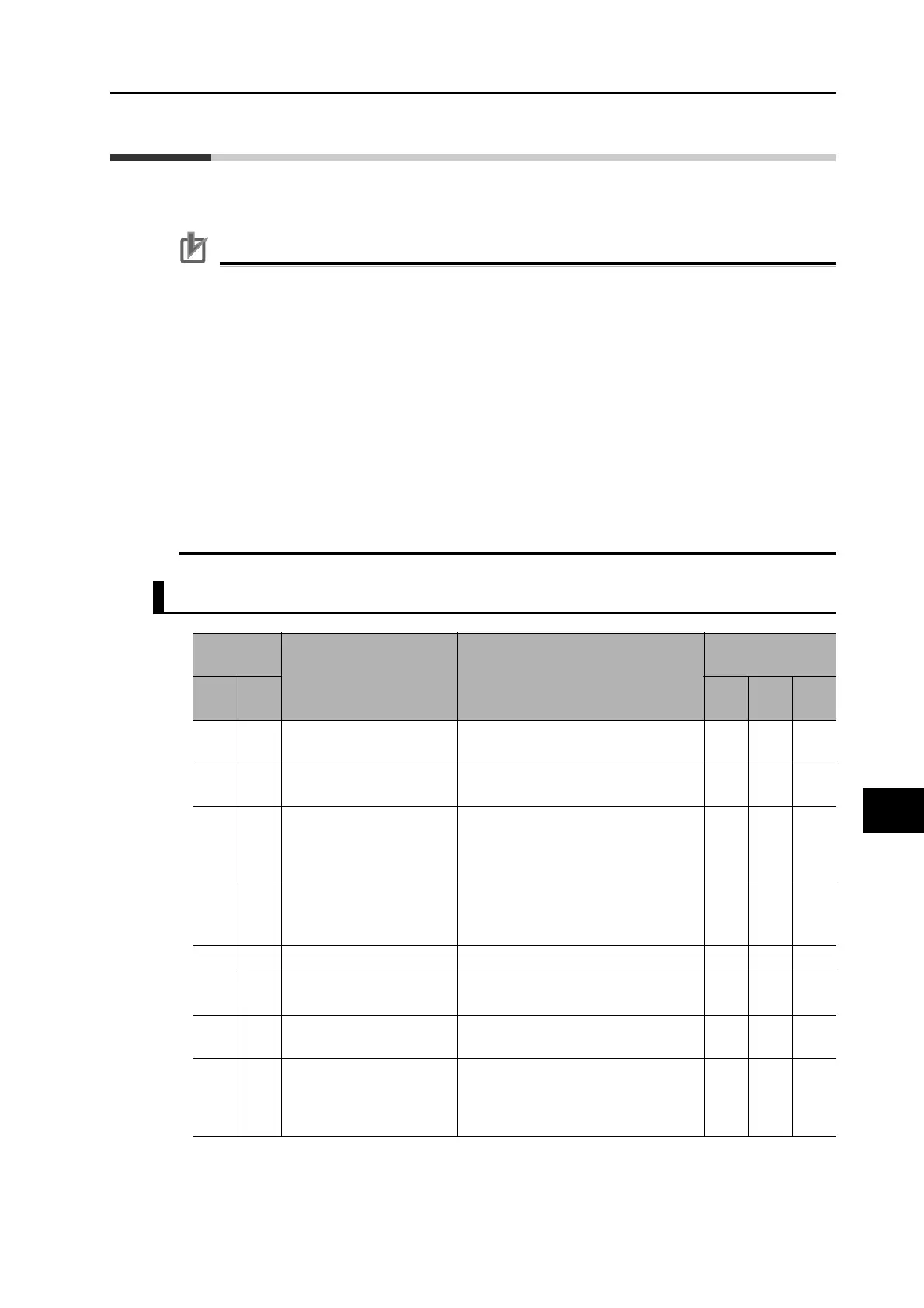

Alarm List

Alarm

number

Error detection function

Detection details and

probable cause

Attribute

Main Sub

History

Can be

reset

Emergency

stop *1

11 0

Control power supply

undervoltage

The DC voltage of the control circuit is

below the specified value.

12 0

Overvoltage The DC voltage in the main circuit is

abnormally high.

13

0

Main power supply

undervoltage

(Insufficient voltage

between P and N)

The DC voltage of the main circuit is

low.

1

Main power supply

undervoltage

(AC cut-off detection)

A location was detected where the

main circuit AC power supply is cut off.

14

0 Overcurrent Overcurrent flowed to the IGBT.

1

IPM error Motor power line ground fault or short

circuit.

15 0

Servo Drive overheat The temperature of the Servo Drive

radiator exceeded the specified value.

16 0

Overload Operation was performed with torque

significantly exceeding the rating for

several seconds to several tens of

seconds.

*2

Loading...

Loading...