Parker Hannifin

P Series User Guide 136

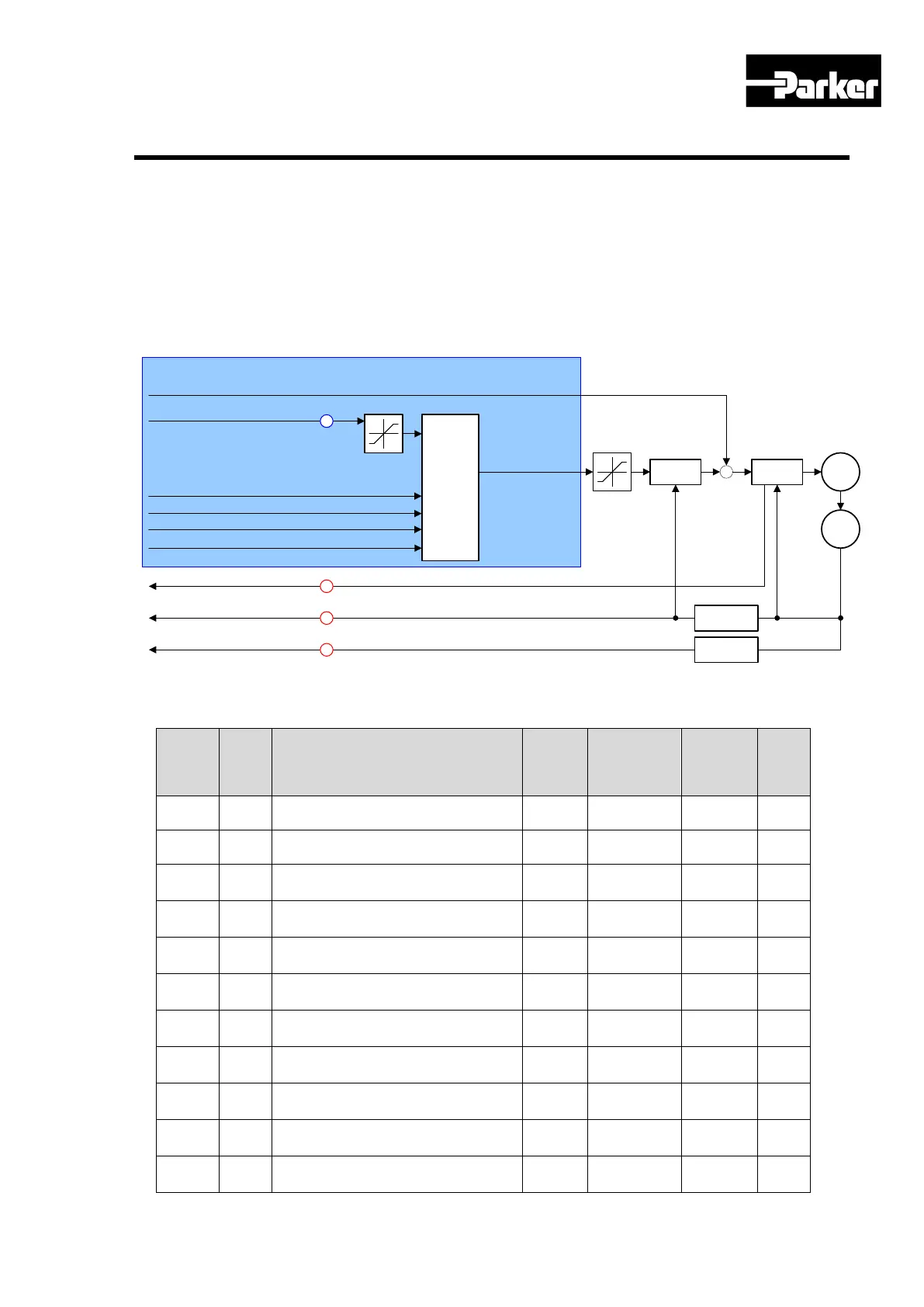

The purpose of torque control is to control such as tension or pressure of machine part by

voltage desired torque from upper controller.

Select ‘3’ in the control mode[0x3000]

For command torque, Enter analog -10[V] ~ +10[V] voltage to no.7 and no.8 on I/O

connector.

The Block diagram of velocity control mode is as below.

Torque Offset (

0x60B2)

Torque Actual Value

(0x6077)

Velocity Actual Value (0x606C)

Position Actual Value (0x6064)

Generate

Torque

Command

Velocity

Control

Torque

Control

+

+

M

Enc.

Velocity

Calculation

Position

Calculation

OP Mode : Torque

6

7

8

1

Analog Torque Command(A-TLMT)

Speed Limit Value at Torque control Mode(0x230E)

Analog Torque Command Filter Time Constant(0x2228)

Analog Torque Input(command/limit) Offset(0x221D)

Analog Torque Input(command/limit) Scale(0x221C)

Index

Index

Name

Format

Accessibility

Allocation

Unit

0x6062 - Position Demand Value DINT RO Yes UU

Position Demand Internal Value

Position Actual Internal Value

0x60B1 - Velocity Offset DINT RW Yes UU/s

0x606C - Velocity Actual Value DINT RO Yes UU/s

Loading...

Loading...