TARGAS-1 Operation Manual V. 1.02 101 support@ppsystems.com

2

maximum. This is the same value as the Max CO

2

value for the Graph setting and can be modified under Main > Settings >

Stops the Injection process and returns to Injection – Settings (Step 2).

Process data is not saved to the USB flash drive.

Stops the Injection process and returns to Injection - Settings (Step 2).

Injection Process results are saved to the USB flash drive.

If the baseline (B) does not drop to either 0 or a very small number (typically 1-3 ppm), then there is either

a leak in the system, or the system has not adequately “zeroed”. Try aborting the process, wait 2-3

minutes, and try again. If the problem persists, check the injection setup for leaks and ensure that the

absorber column is properly seated and contains fresh soda lime.

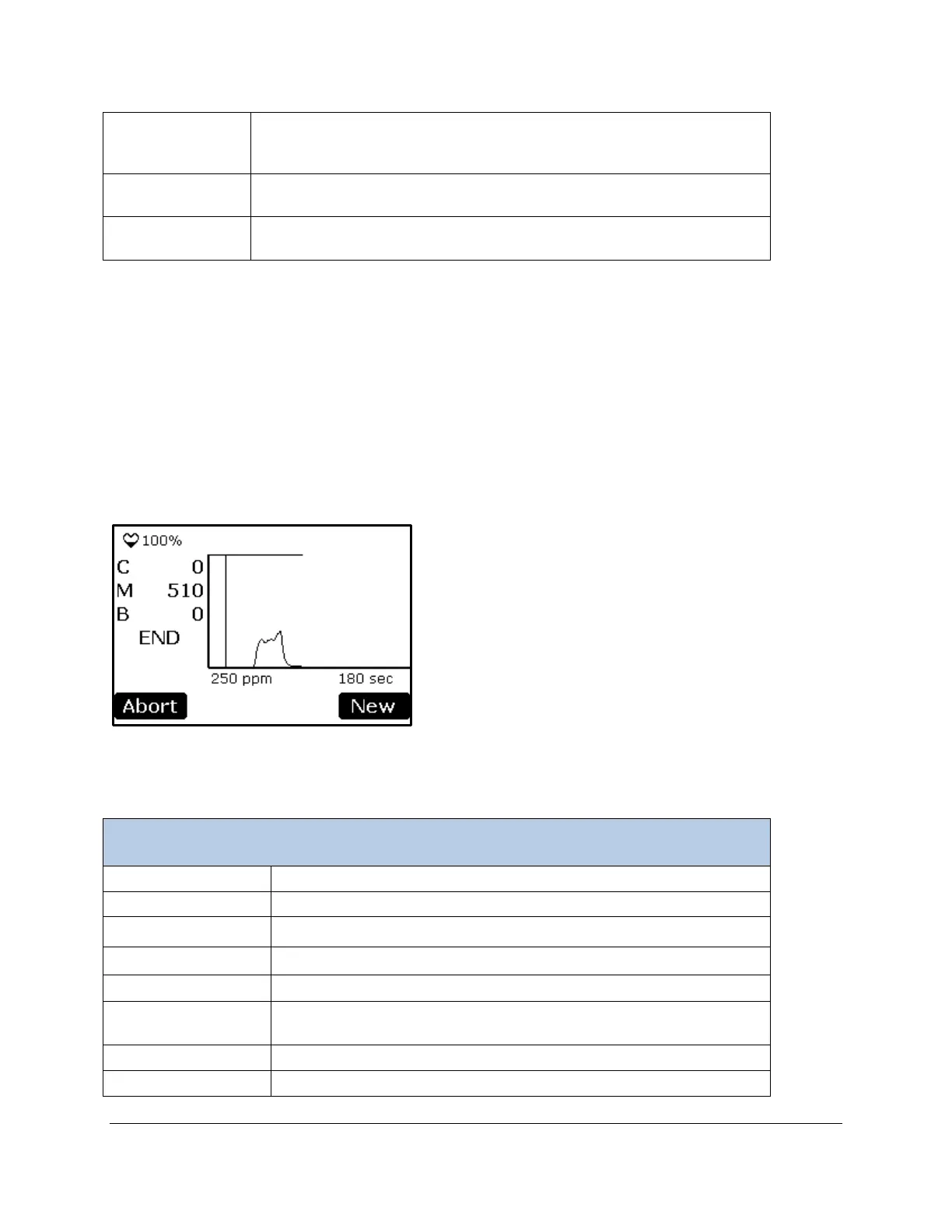

Injection – Injection Phase (Step 6)

During the Injection Phase, the syringe should be slowly and steadily injected into the airstream through

the septum. The injection rate should not exceed 3 ml/second to avoid over-pressurization of the system

(in other words, it should take the user at least 3 seconds to inject a 10 ml syringe).

Pulses to indicate that the system is powered on (power status).

Percentage of battery life remaining (%).

2

concentration in tubing (ppm).

2

concentration inside syringe (ppm).

INJT Indicates that the process is in the injection phase. END

indicates CO

2

concentration calculations have been terminated.

Time (seconds). It is fixed at 180 seconds.

CO

2

concentration in tubing (ppm).

Loading...

Loading...