SECTION 06B: X3 SERIES ELECTRICAL

56

PA1621 Maintenance Manual All Series | Jul 2017

5.6 BATTERY RATING

Each of the 12 volt batteries used on the vehicle

has the following rating:

AGM batteries (PRIME):

Reserve capacity: 200 minutes

Cold cranking (amps): 800 @ 0

o

F (-18

o

C)

Weight (filled): 69 lb (26,7 kg)

The reserve capacity is defined as the number

of minutes a new, fully charged battery at 80

o

F

(26,6

o

C) can be discharged at 25 amperes and

maintain a minimum of 1.75 volts per cell (10.5

volts total for one 12 volts battery). This rating

can be used as a basis for determining how long

a vehicle might run after an alternator failure.

The cold cranking rating is defined as the

minimum discharge current a battery will deliver

in amperes for 30 seconds at 0

o

F (-18

o

C) while

maintaining a minimum of 1.2 volts per cell (7.2

volts total for one 12 volts battery). This rating

can be used as a basis for comparing starting

performance.

5.7 BATTERY TESTING

Several factors influence battery performance.

The methods and inspection procedures

proposed here will ensure your batteries are in

good shape.

5.7.1 Visual Inspection

1. Check the outside of the battery for a broken

or cracked cover or case that could permit

loss of electrolyte. If obvious physical

damage is noted, replace the battery. If the

battery is bulged, replace the battery. Also

check for wet areas around the terminals.

2. Check for loose terminal posts, cable

connections, damaged cables, and for

evidence of corrosion. Correct conditions as

required before proceeding with tests.

3. Check for damaged or loose battery tie-

downs.

5.7.2 Removing Surface Charge

Disconnect cables from the battery and attach

alligator clamps to the contact lead pad on the

battery as shown in Figure 44. Connect a load

equal to half the CCA across the terminal for 5

seconds to remove surface charge from the

battery.

5.7.3 Load Test

This test is one means of checking the battery to

determine its ability to function as required in the

vehicle.

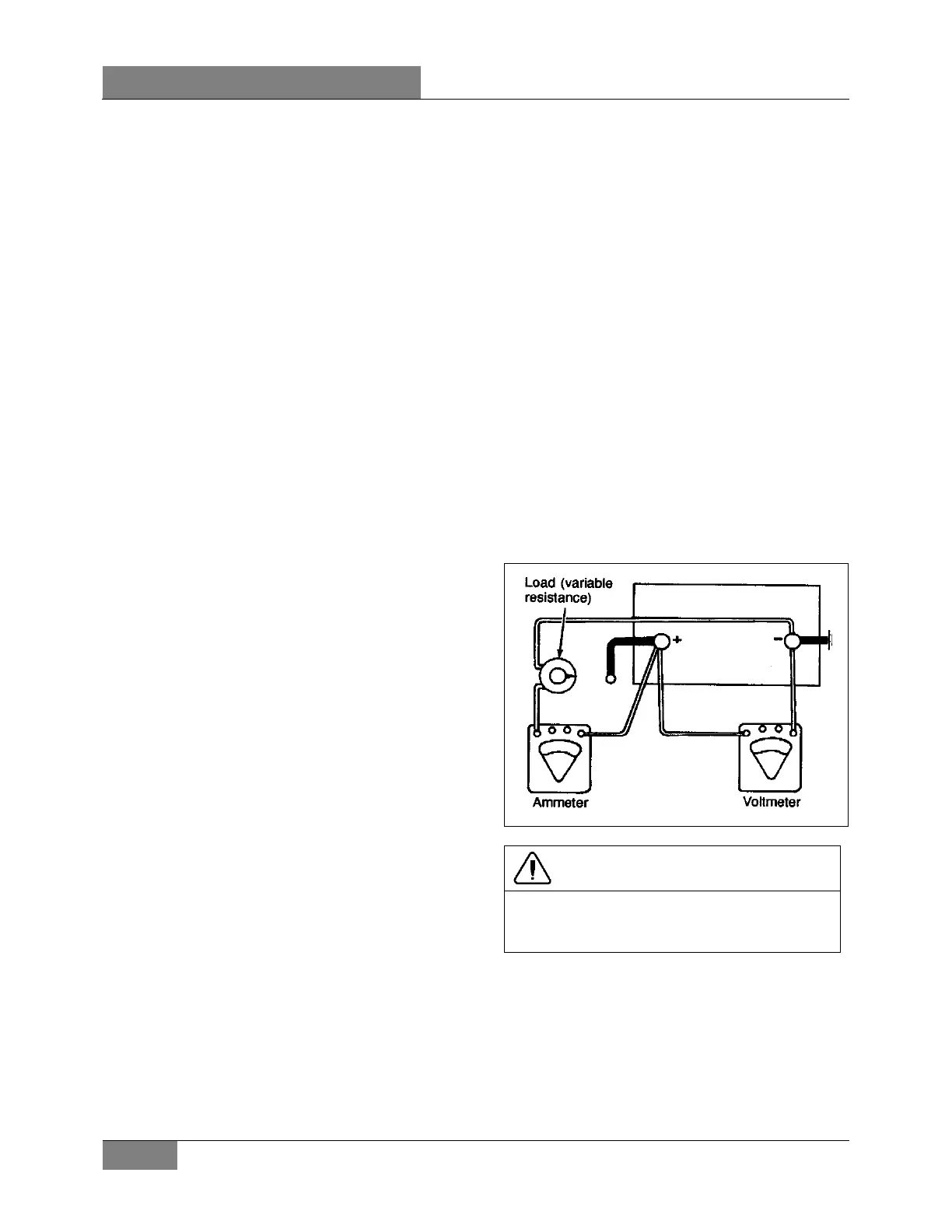

To make this test, use test equipment that will

withstand a heavy electrical load from the

battery, such as a carbon pile resistor along with

an ammeter and volt meter (Figure 43). A

charging system analyzer test equipment may

also be used.

1. Connect a voltmeter, ammeter, and a

variable load resistance as illustrated in

Figure 43.

06064

FIGURE 43: LOAD TEST

CAUTION

Observe polarity of the meters and the battery

when making connections, and select the

correct meter range.

2. Apply a load equal to half the CCA rating @

0

o

F for 15 seconds.

3. With an ammeter reading specified load,

read voltage. The voltage should be at least

9.6 volts. Disconnect the load. If the

voltmeter indicates 9.6 volts or more, the

battery is good. If the voltmeter reading is

less than 9.6 volts, replace the battery. This

voltage is to be used for battery ambient

Loading...

Loading...