SECTION 14: STEERING

PA1621 Maintenance Manual All Series | January 2017

27

13.10.2 Straight Body Type Ball Joint End Play

and Looseness

What creates movement in sockets?

In each straight body type ball joints, the

compressive force of the spring creates resistive

torque by applying a constant load on the

bearing and stud.

As wear occurs on the components, the spring

creates less resistive torque. With less torque,

you no longer have the precise joint needed for

optimum steering, but you do still have a safe

linkage. When all compression is lost, it’s

time to replace the linkage. This wear can be

caused by impact, lack of lubrication and normal

wear.

1. With vehicle engine on, lightly rock the

steering wheel while checking for looseness

in any threaded joint. Observe any

looseness in the two mating tapers or any

movement of the ball pin nut. Any looseness

requires further inspection. If either of the

mating tapered parts shows distortion or

wear, both parts must be replaced.

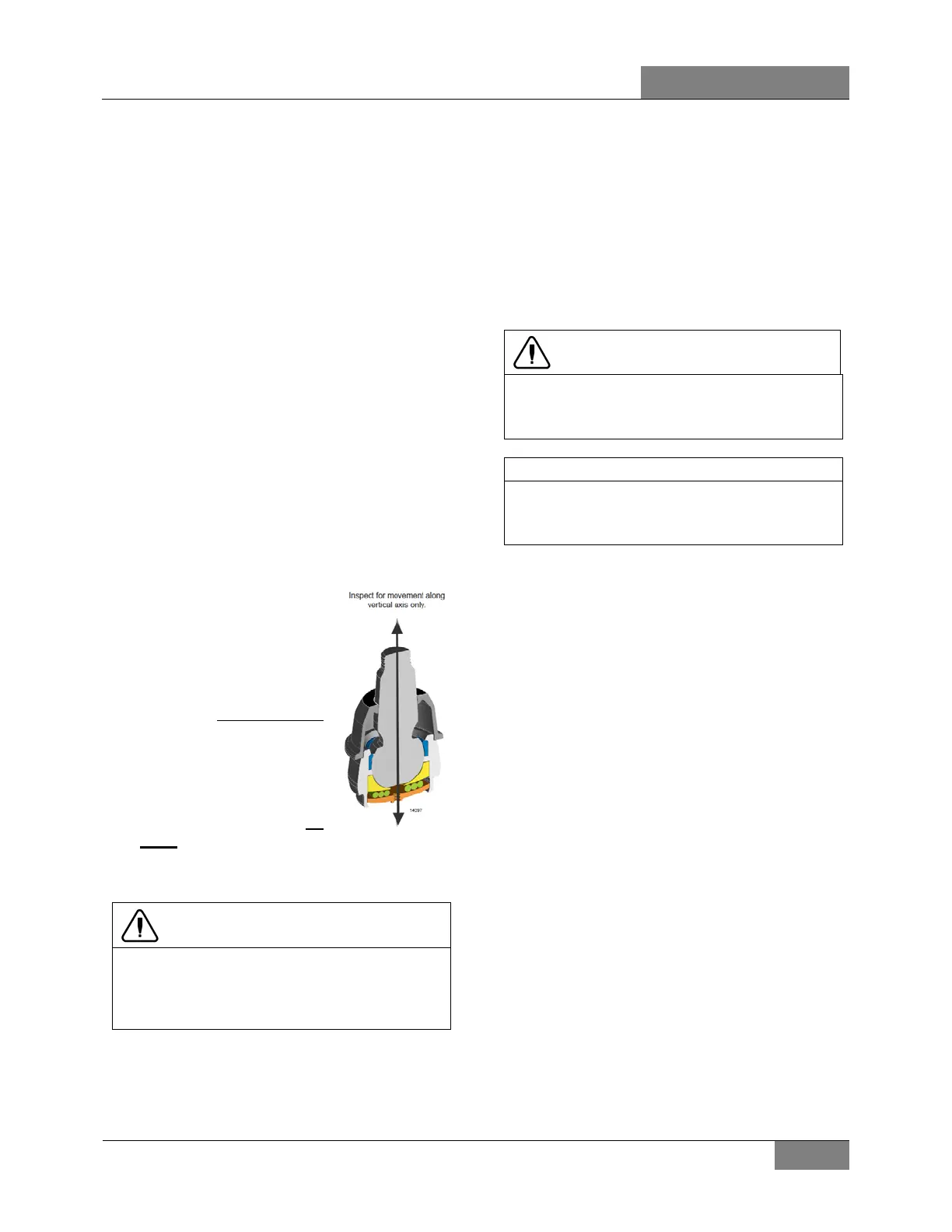

2. With the engine off and

wheels straight ahead and

no force is being exerted

on the linkage by the

steering gear, push and

pull the ball joint in and

out by hand

(approximately 100 lbs.

force) in the direction of

the ball pin. If no

movement is detected, the

ball joint is safe. Any

movement detected by

hand will require the

replacement of the ball

joint.

CAUTION

Do not use a wrench or other object to apply

leverage when inspecting ball joint. Applying

leverage can give distorted results and damage

components.

14. DRIVING TIPS

In order to maximize power steering pump service

life, do not attempt to turn the steering wheel

when the vehicle is stationary, and especially

when service brakes are applied (wheel locking

will oppose the effect of steering geometry which

tends to make the front wheels rotate in opposite

directions).

Persisting in turning, or maintaining the steering

wheel with an extra effort, could make the

hydraulic system work at the relief pressure, and

consequently, cause the hydraulic fluid to become

overheated.

CAUTION

Never maintain the hydraulic system at the

relief pressure for longer than 5/10 seconds to

avoid damaging the power steering pump.

NOTE

Unequal or low tire pressure, oversize tires, and

vehicle overloading are some of the causes that

may increase steering effort.

15. FRONT WHEEL ALIGNMENT

15.1 INDEPENDENT FRONT SUSPENSION

ALIGNMENT

Proper front end alignment must be maintained

to insure ease of steering and provide

satisfactory tire life. When making front end

alignment inspections, the vehicle must be level

and empty with the full weight of the vehicle on

the wheels.

Front end alignment inspections fall into two

groups: regular service inspections performed at

periodic intervals, and inspections to determine

the extent of damage after a collision or severe

service.

Regular service inspections concern toe-in,

camber and caster.

Any variation from the specified alignment will

indicate either a need for adjustment or a more

thorough inspection to determine if parts

replacement is required.

Loading...

Loading...