PA1621 Maintenance Manual All Series | January 2017

2. Remove tie rod ball stud by tapping on

steering arm and bell crank or idler arm with

brass hammer, while using a sledge

hammer to absorb shocks.

If tie rod end assemblies are damaged in any

way, they must be replaced

4.7.2 Installation

1. Install socket end assemblies on tie rod. Be

sure both ends are threaded an equal

distance into the tube.

2. Make sure threads on stud and in stud nut

are clean and not damaged.

3. Position ball studs (socket ends of tie rod) in

holes in steering arm and bell crank or idler

arm. Ball stud and taper bore must be clean

and free of grease. Install a ball stud nut on

each stud and tighten firmly.

4. Torque stud nuts to prescribed torque (refer

to Torque Table 2). Align cotter pin slot

(tighten) and install a new cotter pin.

Adjust toe-in as directed under heading "Toe-

In Adjustment" in this section.

5. Make sure tie rod ends are properly aligned

with ball studs, and then torque tie rod end

clamp bolts to prescribed torque (refer to

Torque Table 2).

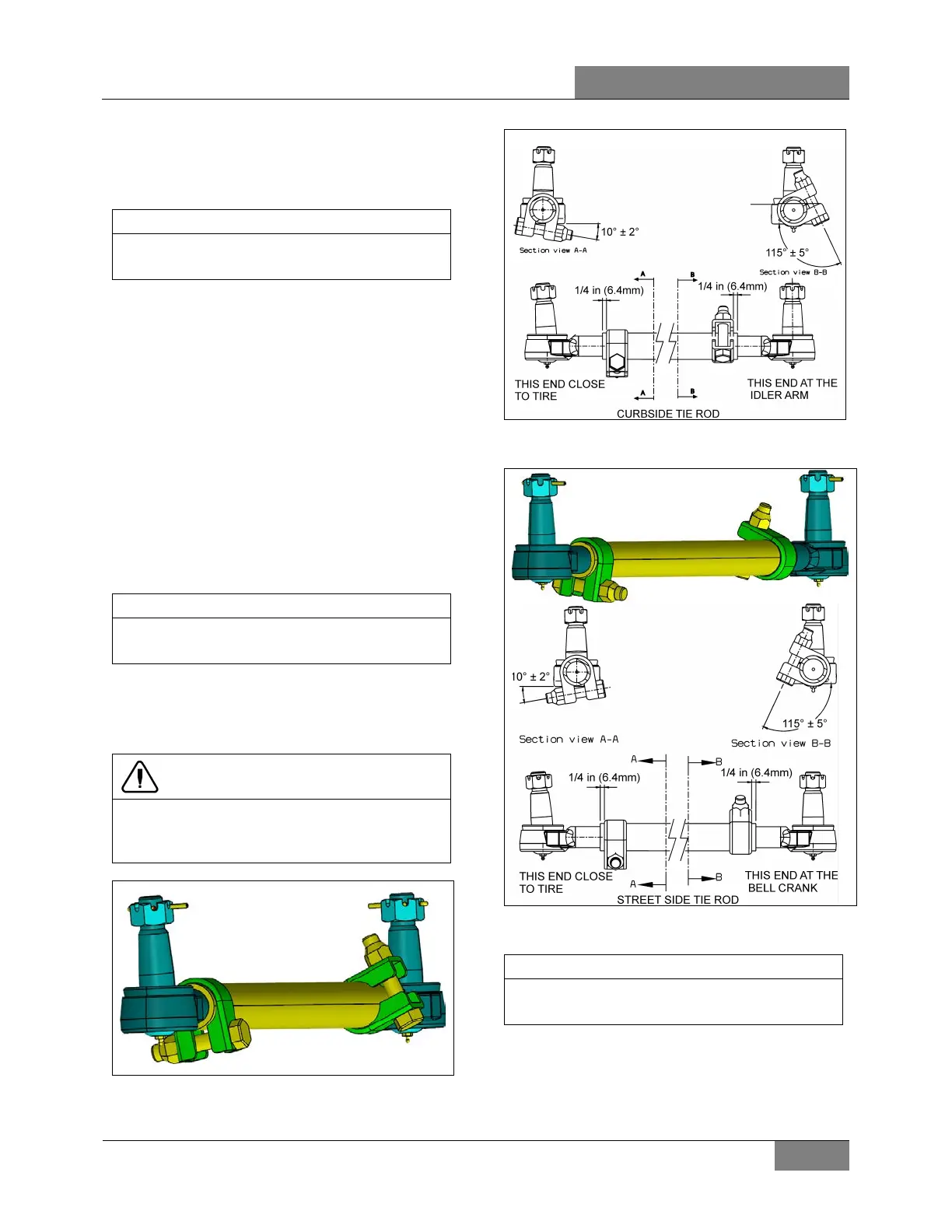

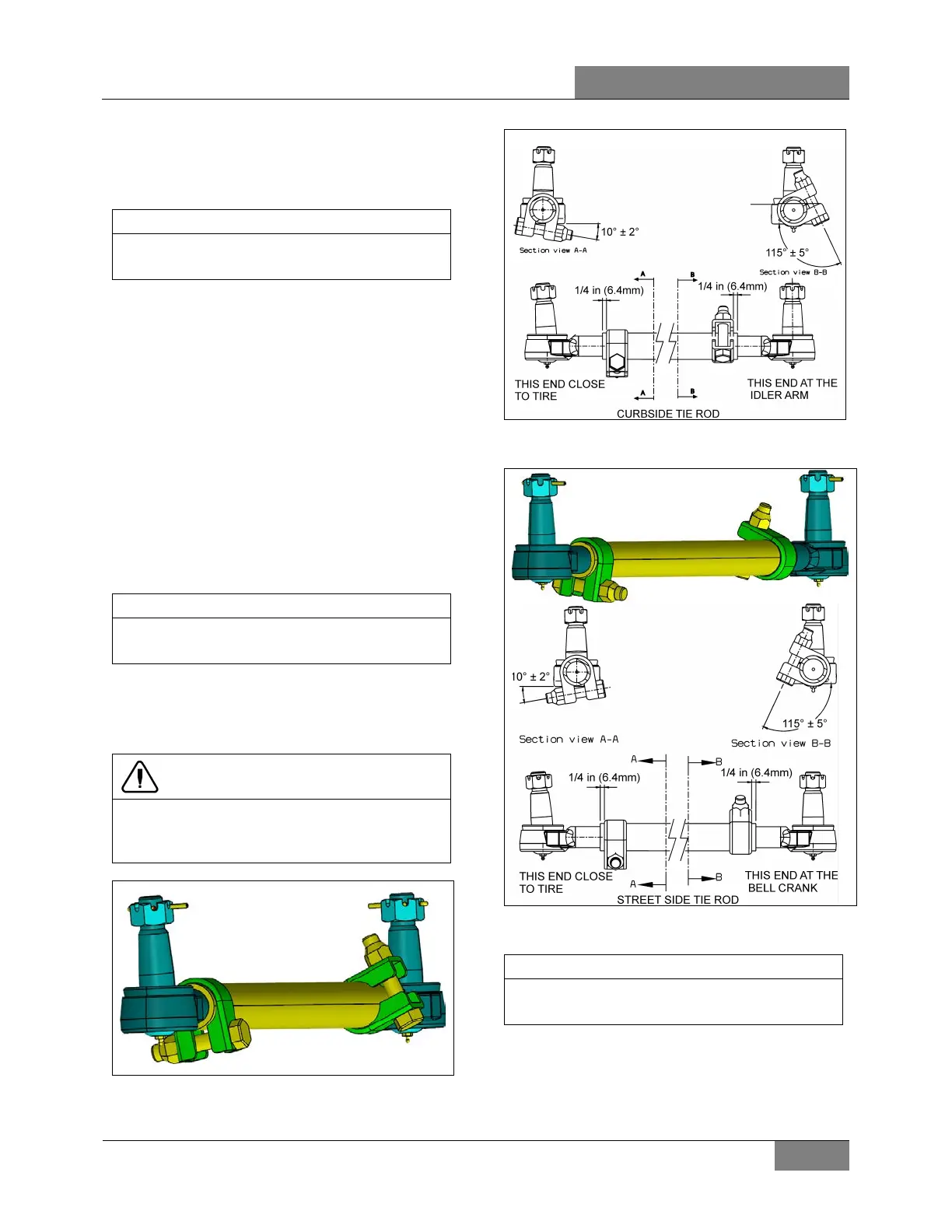

CAUTION

Reinstall tie rod clamp as per FIGURE 17 &

FIGURE 18 as they might interfere with other

components.

FIGURE 17: CURBSIDE TIE ROD - CLAMPS POSITION

16199

FIGURE 18: STREET SIDE TIE ROD - CLAMPS POSITION

16200

If tie rod is not properly aligned with stud,

binding will result.

4.8 STEERING ARMS

The left and right wheel steering arms are

secured to a steering knuckle at one end and to

a tie rod at the other end.

Loading...

Loading...