SECTION 14: STEERING

18

PA1621 Maintenance Manual All Series | January 2017

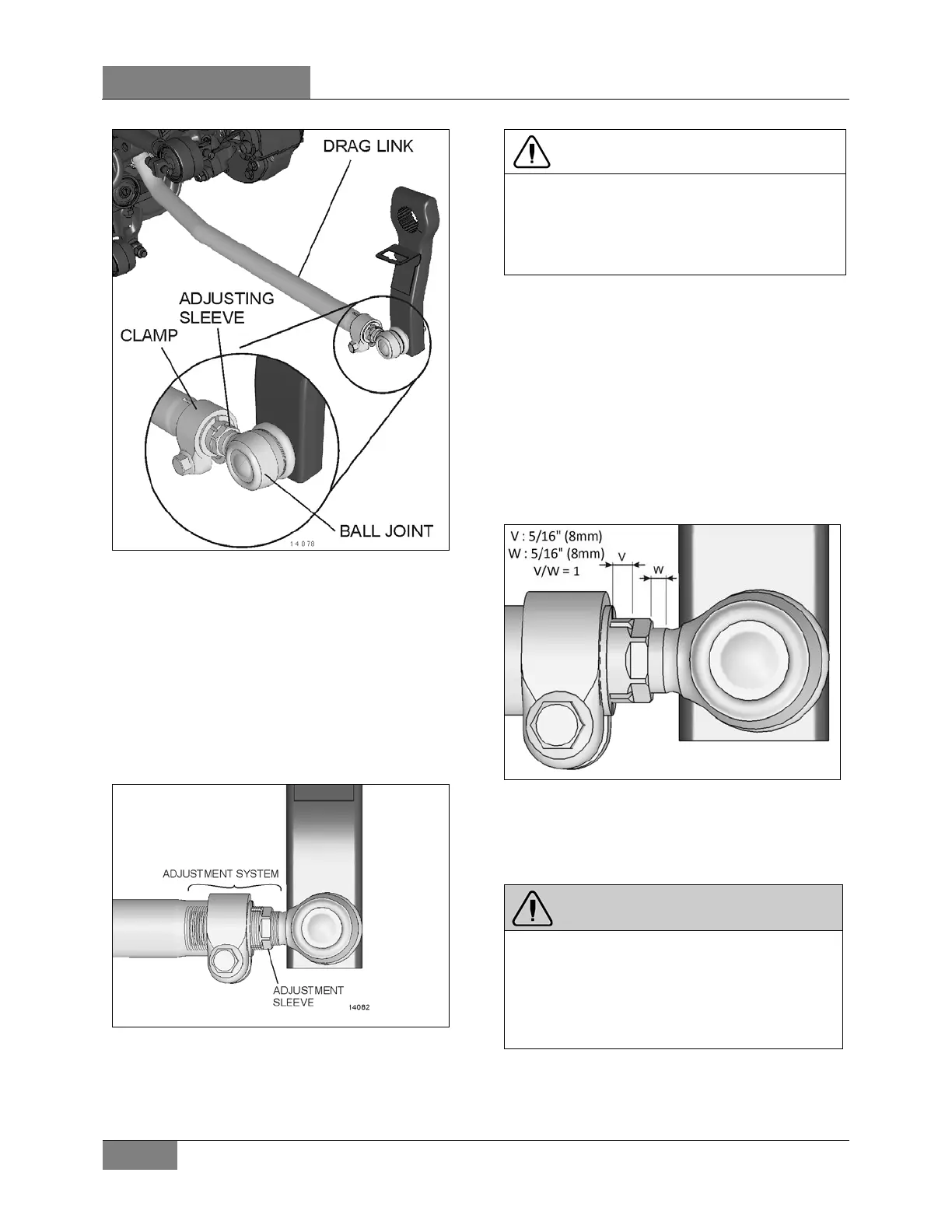

FIGURE 22: DRAG LINK

12.1 FINE ADJUSTMENT

The drag link fore end is provided with an

adjusting sleeve which has internal and external

left and right threads. Turning this sleeve allows

fine adjustments to the length of the draglink.

Apply a small amount anti-seize compound on

the threads for corrosion protection. Be sure to

avoid smearing the ball joint boot.

FIGURE 23: DRAG LINK ADJUSTMENT SYSTEM

CAUTION

Too little pressure on the clamp can destroy the

threaded adjustment system sleeve.

Apply the recommended torque for clamp nut.

TORQUE: 118-133 lb-ft (160-180 Nm)

Fine adjustment of the drag link length should

be performed exclusively by turning the adjuster

sleeve.

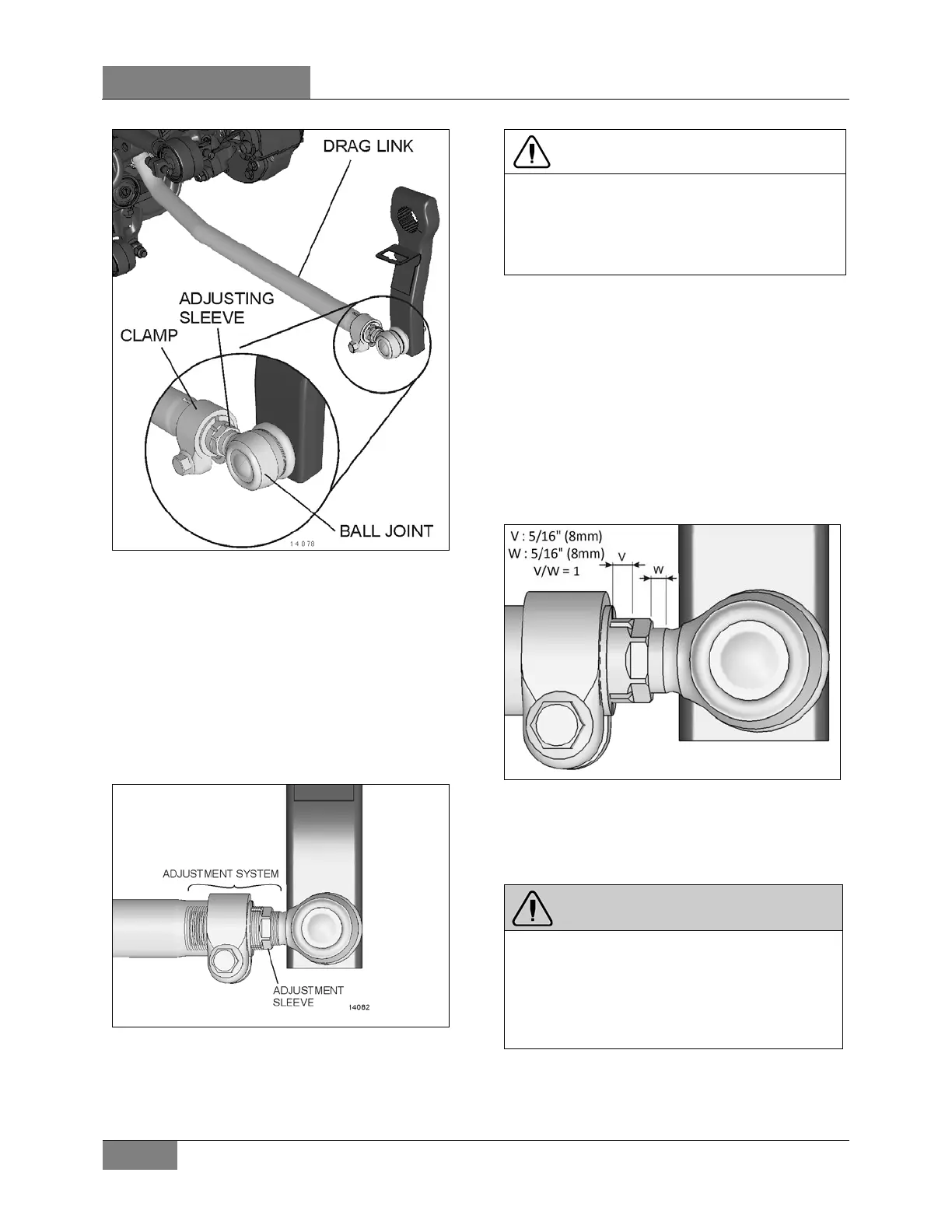

12.1.1 Adjustment System Thread Lengths

When assembling the adjuster sleeve or ball

joint, be sure to assemble the parts within the

following prescribed thread lengths and values.

Lengths V and W should be measured prior to

removal to restore the steering system to its

original state.

FIGURE 24: DRAG LINK ADJUSTMENT SYSTEM

Dimension V and W should be equal: V/W = 1

Dimension V: 5/16″ (8mm)

Dimension W: 5/16″ (8mm)

WARNING

To preserve the integrity of the adjusting

system, length V and W should never exceed

5/8″(16mm) ± 1 thread pitch.

Length V and W should be equal within ±

1mm

Loading...

Loading...