SECTION 13: WHEELS, HUBS AND TIRES

8

PA1621 Maintenance Manual All Series | January 2017

CAUTION

Wheel studs and nuts must be kept free from

grease and oil. No lubricant whatsoever

should be used. Cleanliness of the wheel and

its rotor mating surfaces is important for

proper wheel mounting.

It is recommended to add some rust protection

lubricant on the outside diameter of the hub (to

facilitate future removal).

It is also important that wheel stud nuts be

tightened alternately on opposite sides of the

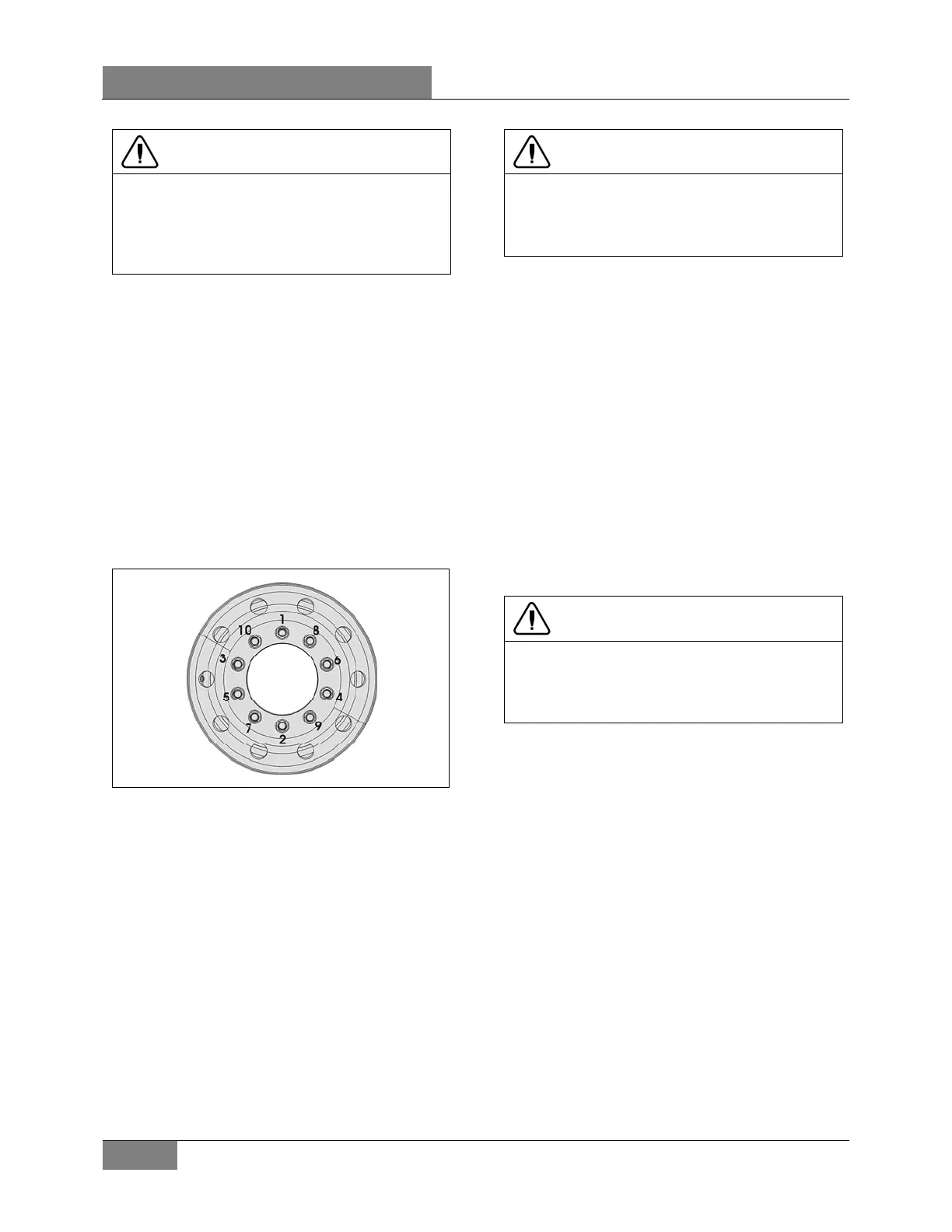

wheel. Refer to Figure 3 for the suggested

tightening sequence.

3.1 INSPECTION

Tighten stud nuts progressively as shown in

Figure 3. The final tightening should be done

with a torque wrench.

TORQUE (aluminum & steel wheels):

450-500 lb-ft (610-678 Nm)

FIGURE 3: TIGHTENING SEQUENCE 13018

3.2 SINGLE WHEEL REMOVAL

1. Stop engine and apply parking brake.

2. Loosen wheel nuts about one turn (do not

remove the nuts). This is not necessary if

equipped with hydraulic powered gun.

3. Raise the vehicle by its jacking points on the

body. See Section 18, "Body", under heading

"Vehicle Jacking Points";

4. Unscrew wheel hex stud nuts and remove

the wheel;

CAUTION

Always mark position of the wheel on the axle

prior to removal in order to replace wheel at

the same location, thus avoiding a new wheel

balancing.

3.3 SINGLE WHEEL INSTALLATION

1. Mount the wheel over studs, being careful

not to damage stud threads;

2. Screw in the hex stud nuts (refer to Figure 3

for sequence) so that wheel will position itself

concentrically with hub. This is important,

otherwise wheel may be eccentric with hub

and will not run straight. In this initial step,

slightly tighten the nuts to correctly position

the wheel;

3. Tighten stud nuts progressively as shown in

Figure 3. The final tightening should be done

with a torque wrench.

TORQUE (aluminum & steel wheels):

450-500 lb-ft (610-678 Nm)

CAUTION

Insufficient mounting-torque can result in

damage to parts. Excessive mounting torque

can cause studs to break and the wheel to

crack in stud hole area.

4. DUAL WHEELS

4.1 OUTER WHEEL REMOVAL

Same as described in "Single Wheel Removal"

procedure described previously.

4.2 INNER WHEEL REMOVAL

1. Remove outer wheel;

2. Remove inner wheel.

4.3 INNER WHEEL INSTALLATION

Mount the wheel over studs, being careful not to

damage stud threads;

4.4 OUTER WHEEL INSTALLATION

With inner and outer wheels installed, tighten

the stud nuts progressively as shown in Figure

3. The final tightening should be done with a

torque wrench.

Loading...

Loading...