SECTION 14: STEERING

PA1621 Maintenance Manual All Series | January 2017

17

the rod end. Install washers. Tighten nut and

install a new cotter pin. Depending on axle

type, select the appropriate torque,

IFS, TORQUE: 245-270 lb-ft (332-366 Nm)

I-BEAM, TORQUE: 165-236 lb-ft (224-320 Nm)

CAUTION

Input shaft marks must be aligned before

adjusting pitman arm.

11.3 ADJUSTMENT

1. Disconnect the drag link from pitman arm.

Center steering wheel by dividing the total

number of steering wheel turns in two. Scribe

a reference mark on steering gearbox at the

center previously determined.

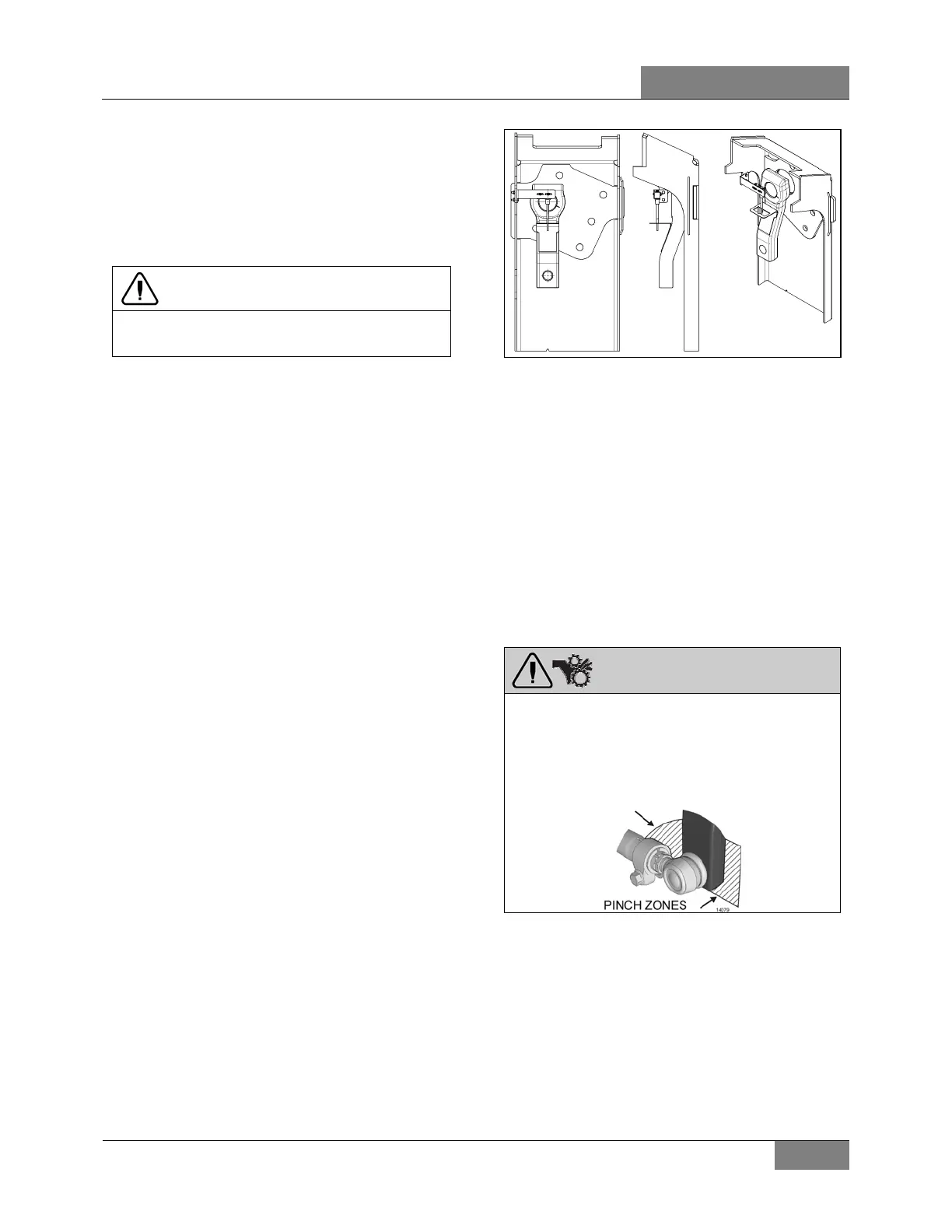

2. Using a protractor, check the angle of the

pitman arm (refer to Figure 18 & Figure 19

for details).

3. The pitman arm should be adjusted with

reference marks aligned or to an angle of 2.5º

towards front of vehicle (I-Beam axle) or 0°

(Independent Front Suspension) in relation

with the vertical axis. If not, unscrew and

remove fixing nut. Remove the pitman arm

according to the procedure outlined under

previous heading "Pitman arm removal".

Adjust to the proper angle.

4. When adjustment is achieved, replace fixing

nut and tighten

TORQUE: 470-570 lb-ft (637-773 Nm)

11.4 TAG AXLE UNLOADING SWITCH

ADJUSTMENT (OPTIONAL)

1. Make sure vehicle wheels are straight and

facing forward.

2. Line up switch lever with reference to the

bracket center (Refer to Figure 21).

FIGURE 21: TAG AXLE UNLOADING SWITCH

ADJUSTMENT

14061

12. DRAG LINK (I-BEAM AXLE)

The draglink on your vehicle connects the

steering gear pitman arm to the front axle’s

steering arm.

For additional details please refer to ZF

assembly instructions LMN404-3 and Lemförder

service information leaflet for the fine adjustment

system.

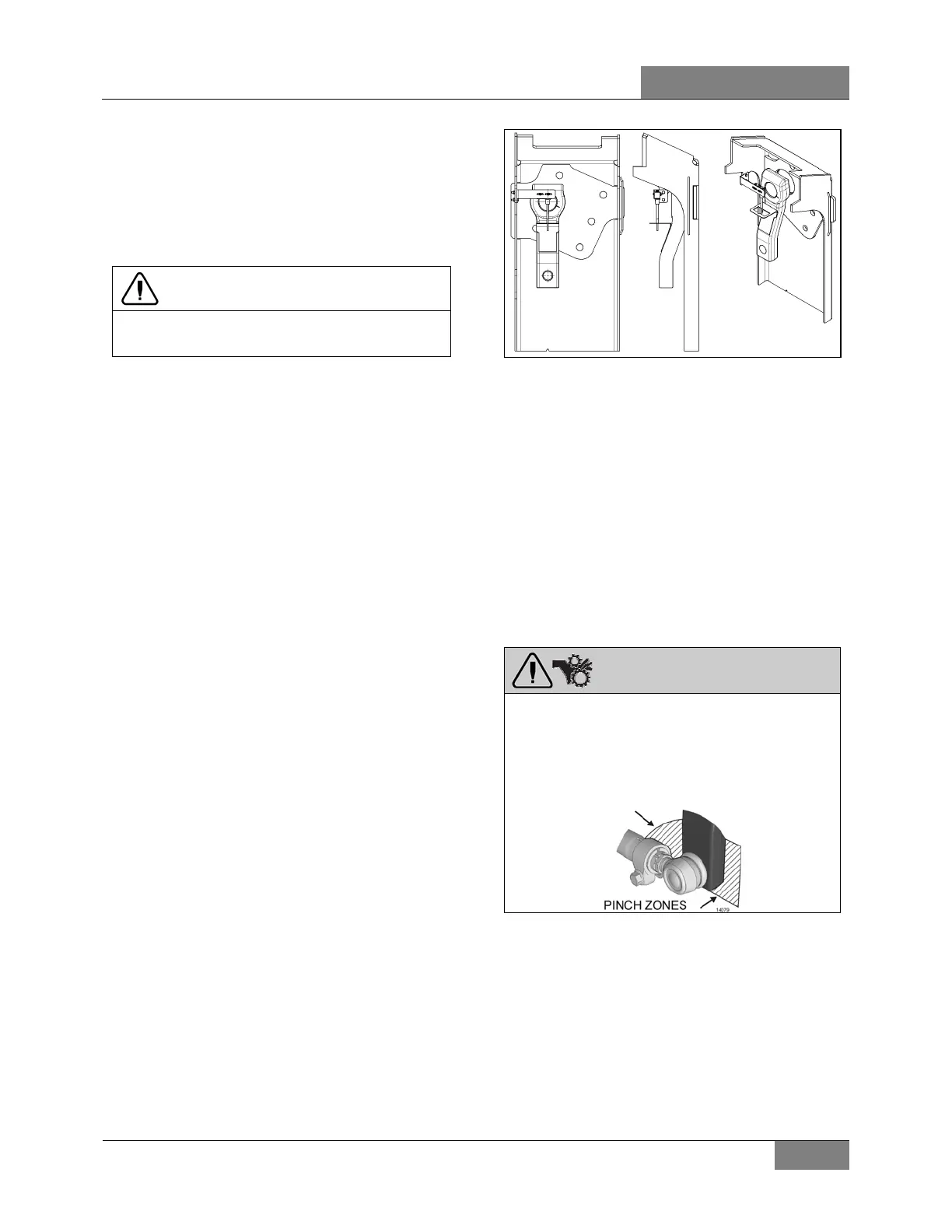

PINCH HAZARD

Keep hands and fingers clear of pinch zones

around pitman arm.

Pinch zones are between pitman arm and

clamp, and between front of pitman arm and

vehicle structure.

Loading...

Loading...