SECTION 11: REAR AXLES

PA1621 Maintenance Manual All Series | January 2017

9

remember to replace them afterwards.

7. Disconnect the brake chamber hoses.

NOTE

Position the hoses so they will not be damaged

when removing the axle.

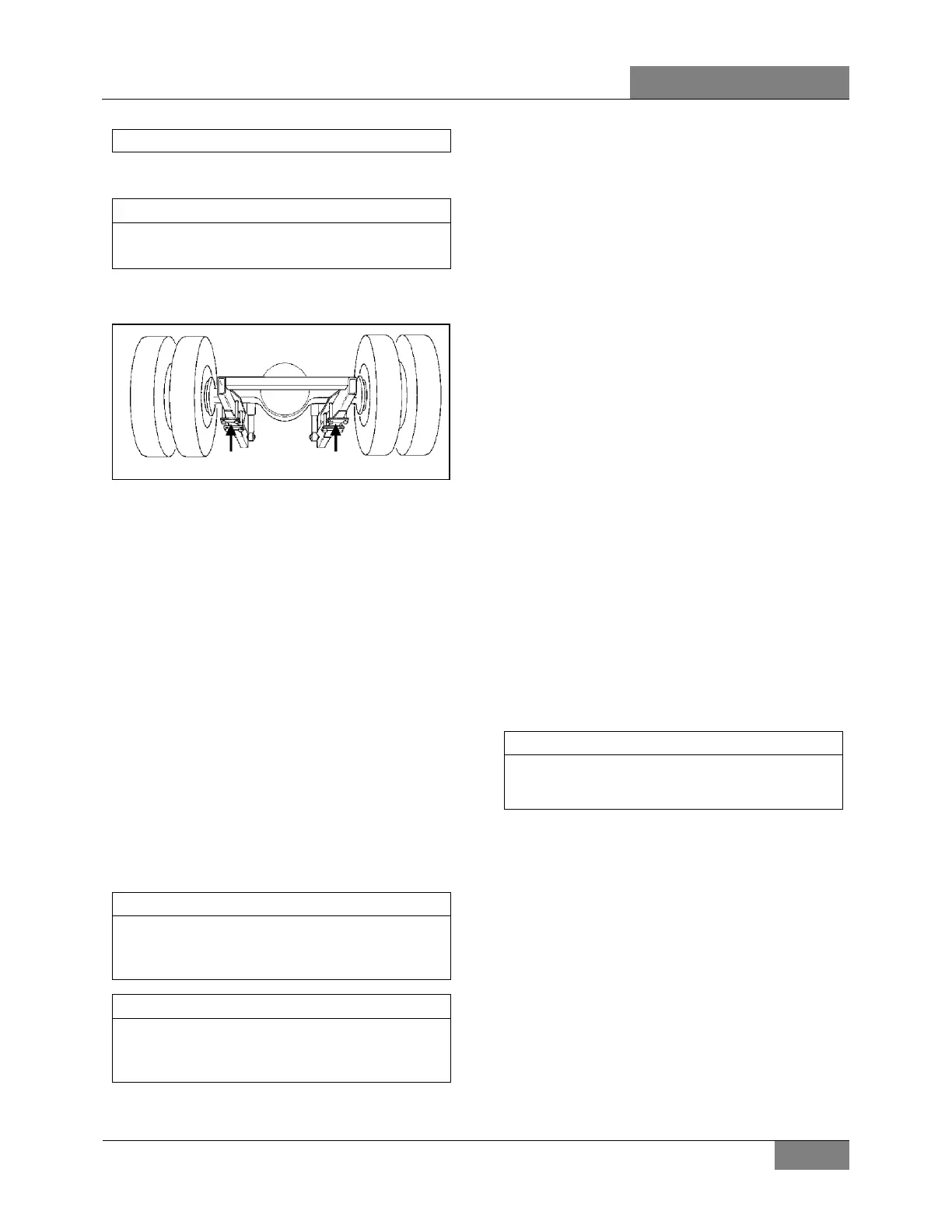

8. Install jacks under the axle jacking points to

support the axle weight (refer to Figure 6).

FIGURE 6: JACKING POINTS ON DRIVE AXLE H3B762

9. Remove the four shock absorbers as

outlined in Section 16: Suspension under

heading Shock Absorber Removal.

10. Remove the sway bar.

11. Remove the lower and upper longitudinal

radius rod supports from vehicle sub-frame

as outlined in Section 16: Suspension,

under heading "Radius Rod Removal".

12. Remove the transversal radius rod support

from the vehicle sub-frame.

13. Remove the two retaining nuts from each of

the four air bellows lower mounting

supports.

14. Use the jacks to lower axle. Carefully pull

away the jacks axle assembly from

underneath vehicle.

15. Reverse removal procedure to reinstall drive

axle.

NOTE

Refer to Section 16: Suspension for

suspension components proper tightening

torques.

NOTE

Refer to section 13 "Wheels, Hubs And Tires"

for correct wheel bearing adjustment

procedure.

2.5 DISASSEMBLY AND REASSEMBLY

Disassembly and re-assembly procedures are

covered under applicable headings in Meritor's

"MAINTENANCE MANUAL, NO. 5A", found on

your Technical Publications USB flash drive.

2.6 GEAR SET IDENTIFICATION

Gear set identification is covered under

applicable heading in Meritor's "MAINTENANCE

MANUAL NO. 5A", found on your Technical

Publications USB flash drive.

2.7 ADJUSTMENTS

Adjustments are covered under applicable

headings in Meritor's "MAINTENANCE MANUAL

NO. 5A", found on your Technical Publications

USB flash drive.

2.8 FASTENER TORQUE CHART

A differential fastener torque chart is provided in

Meritor's "MAINTENANCE MANUAL NO. 5",

found on your Technical Publications USB flash

drive.

2.9 TIRE MATCHING

Drive axle tire matching is covered under the

applicable heading in Section 13, "Wheels, Hubs

And Tires" in this manual.

2.10 DRIVE AXLE ALIGNMENT

NOTE

For drive axle alignment specifications, refer

to paragraph 2.10.2 ‘’ Drive Axle Alignment

Specifications’’ in this section.

The drive axle alignment consists in aligning the

axle according to the frame. The axle must be

perpendicular to the frame. The alignment is

achieved with the use of shims inserted between

the lower longitudinal radius rod supports and

the frame.

Drive axle alignment is factory set and is not

subject to any change, except if the vehicle has

been damaged by an accident or if there are

requirements for replacement.

If the axle has been removed for repairs or

servicing and if all the parts are reinstalled

exactly in the same place, the axle alignment is

not necessary. However, if the suspension

supports have been replaced or altered,

proceed with the following instructions to verify

or adjust the drive axle alignment.

Loading...

Loading...