SECTION 12: BRAKE AND AIR SYSTEM

22

PA1621 Maintenance Manual All Series | January 2017

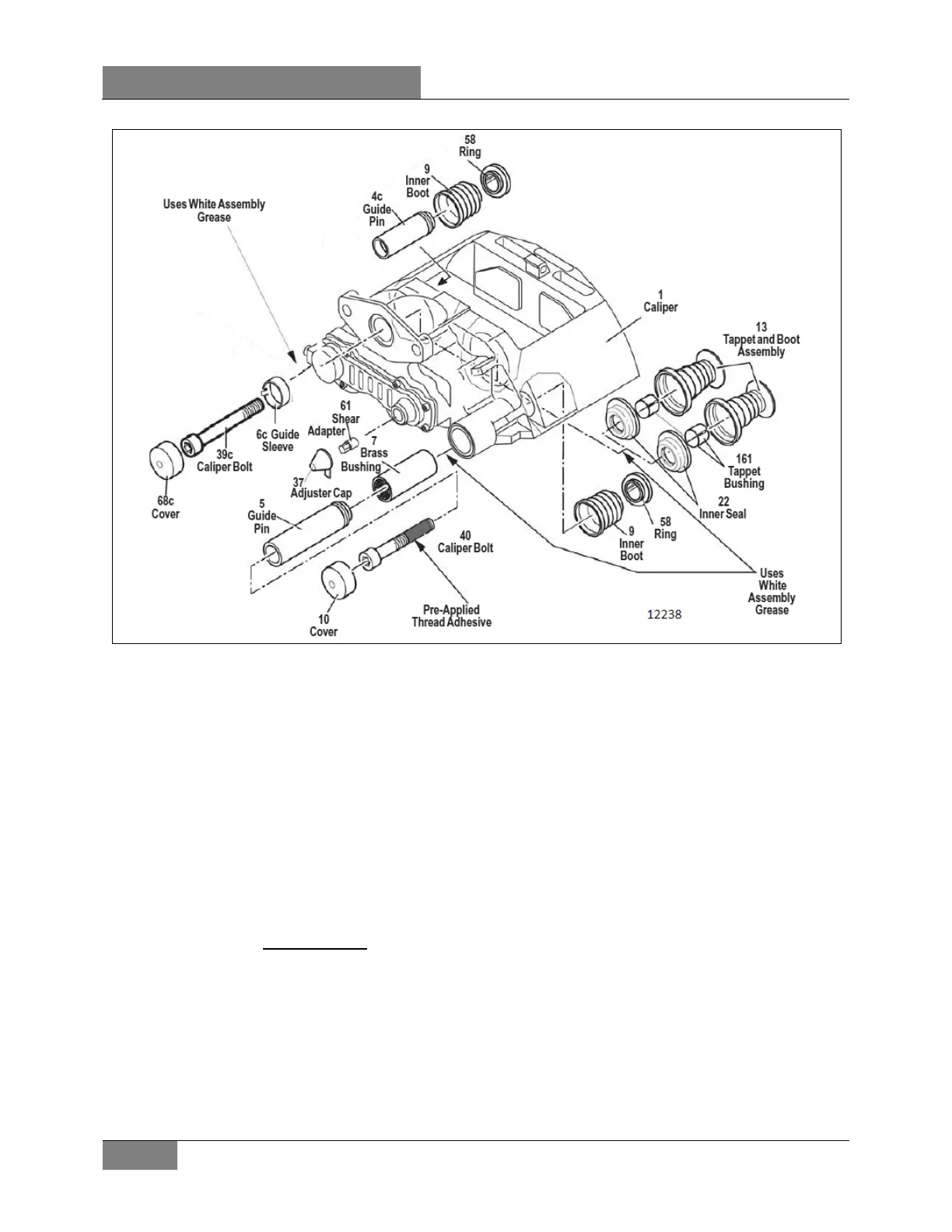

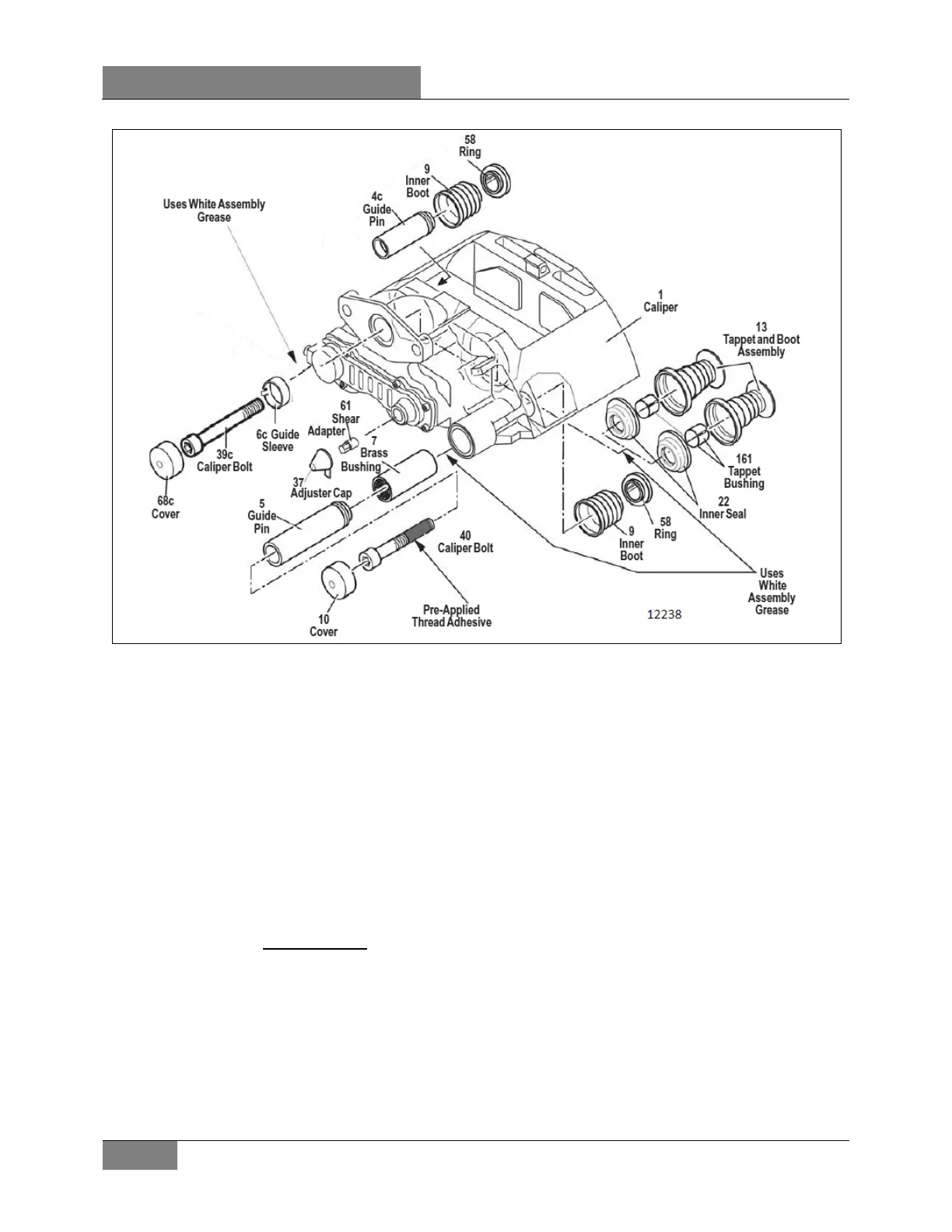

FIGURE 22: BRAKE COMPONENTS

27.2 PAD REPLACEMENT - ADJUSTER

Brake pad replacement procedure has slightly

changed with the introduction of the new N2G

slack adjuster on the vehicles.

After fitting new pads,

1. Turn the adjuster (thru shear adapter)

clockwise until the pads come into

contact with the disc.

2. Then turn back the adjuster counter-

clockwise three “clicks” and check

the caliper running clearance.

During the turning of the adjuster, you will

notice a changed clicking noise. It is not

caused by a defect of the mechanism.

Also the “feel” during the rotation of the

adjuster and the position of the spanner

after the 3 clicks has changed.

Depending on the age of the vehicle, it may

have installed on it two different design levels of

disc brake and so there may be 2 different

clicking noises and final positions of the adjuster

on the vehicle.

The full wording of the processes is included in

the latest Knorr-Bremse service manual.

Refer to Knorr-Bremse Pneumatic Disc Brake

Y006471 Service Manual.

27.3 CHECKING DISC BRAKE PADS

Brake pads have to be checked on a regular

basis depending on the vehicle operation. The

remaining thickness of the pads should never be

less than 0.079 in (2 mm). When replacing

brake pads, all four pads on an axle have to be

changed at the same time. There is no inner or

outer pad, since all pads are the same. Once

removed, worn pads should be replaced in their

original position.

Loading...

Loading...