SECTION 13: WHEELS, HUBS AND TIRES

PA1621 Maintenance Manual All Series | January 2017

13

9.1 TAG AXLE HUB BEARING INSPECTION

MAINTENANCE

Tag axle unitized bearing

Unitized bearing inspection should be made

at the intervals specified by the Lubrication

And Servicing Schedule in Section 24:

LUBRICATION & SERVICING..

1. Apply parking brake, raise wheels off the

ground and support axle on stands.

2. When the wheels are raised, they should

revolve quite freely without roughness.

3. Place magnetic base of a dial indicator on

brake caliper and position dial indicator stem

against a convenient marked spot on face of

hub flange.

4. With dial indicator in position pull hard but

steadily on hub flange and oscillate at same

time until a steady reading is achieved.

5. Without releasing the pressure, turn bearing

so that dial indicator stem contacts marked

spot and note reading on indicator.

6. Push bearing flange hard and oscillate as

before until a steady reading is achieved.

7. Without releasing the pressure, turn bearing

so that indicator stem again contacts the

marked spot and note new reading on

indicator.

8. The difference between readings is the

amount of mounted end play in bearing unit.

9. Refer to the following table for allowed end

plays:

New Tag Axle Unitized Hub Bearing Axial

Endplay

Maximum axial

clearance/end

play

0.0024 inch (0.061mm) based

on clamp load of 20000 lbf

(90kN).

Tag Axle Unitized Hub Bearing Axial

Endplay In Service

If the endplay is between 0 – 0.002 in (0 –

0.05 mm), the inspection is complete.

If the endplay is greater than 0.002 in (0.05

mm), but less than 0.008 in (0.20mm),

check and retighten the wheel bearing

adjusting nut. Again check endplay to make

sure that the clamping process is done

properly.

If the endplay is equal to or greater than

0.008 in (0.20mm), replace the unitized hub

bearing as soon as possible since the hub

assembly may not be safe to operate.

9.2 TAG AXLE HUB BEARING REMOVAL

1. Stop engine and apply parking brake.

2. Loosen wheel nuts about one turn (do not

remove the nuts). This is not necessary if

equipped with hydraulic powered gun.

3. Raise the vehicle by its jacking points on the

body. See Section 18, "Body", under

heading "Vehicle Jacking Points".

4. Unscrew 10 wheel hex stud nuts and

remove the wheel.

5. Unscrew 14 hub flange hex cap screws.

Discard hub flange cap screws (single-

use only).

6. Remove hub flange and rotor.

7. Unscrew hub nut.

8. Remove hub nut and thrust washer.

9.3 TAG AXLE HUB BEARING INSTALLATION

1. Clean spindle using EFX degreaser (Prevost

#685313)

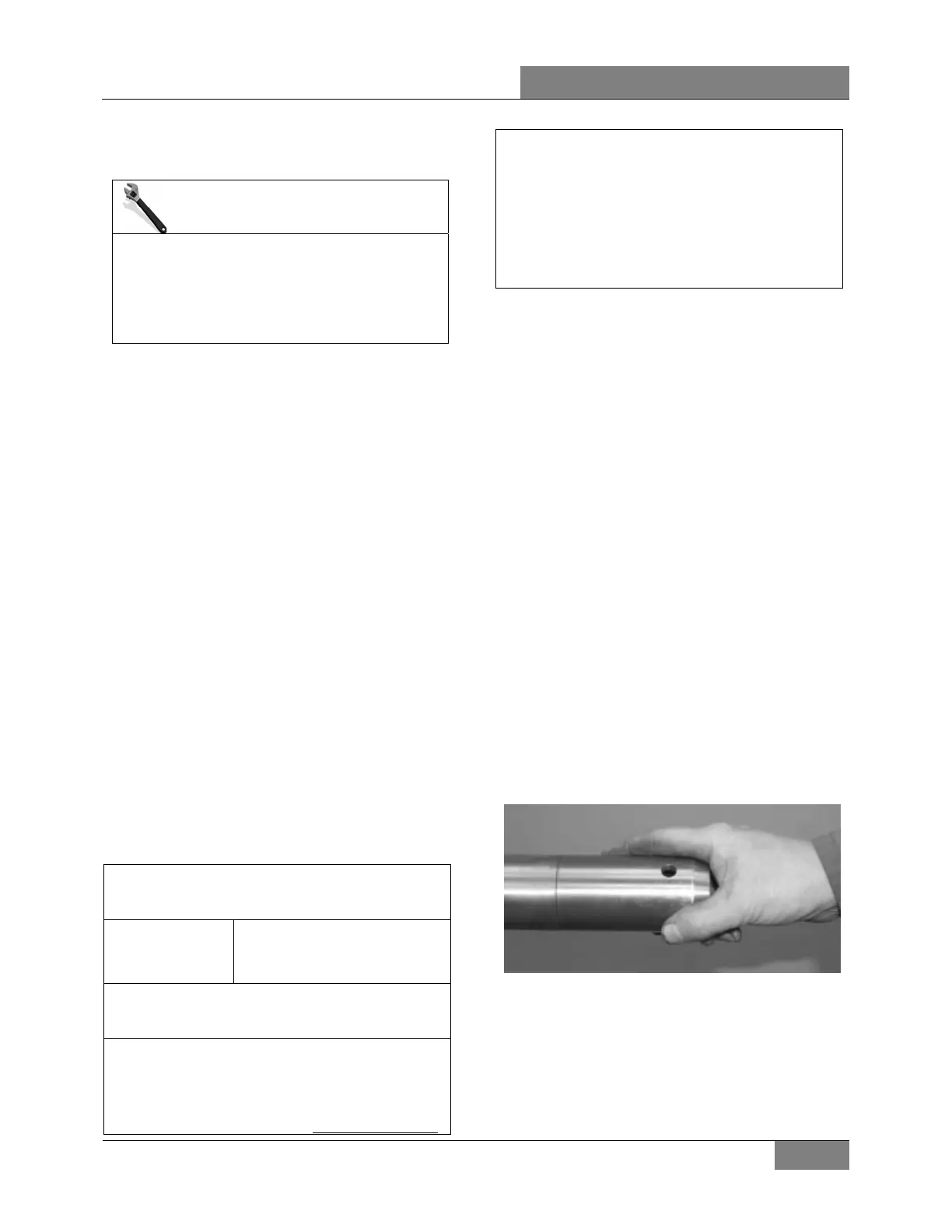

2. Screw insertion tool onto spindle (FIGURE

9).

FIGURE 9: INSERTION TOOL PREVOST P/N 491115

3. Apply a thin layer of antifriction/antifretting

lubricant on spindle where bearing will be

located (use Gleitmo 805 grease, Prevost

#685274).

Loading...

Loading...