SECTION 14: STEERING

26

PA1621 Maintenance Manual All Series | January 2017

2. Thoroughly grease rubbing pad and ball pin

with Shell Retinax LX or equivalent.

3. Insert ball pin into body.

4. Insert thrust cap, compression spring and

adjuster piece into body.

5. Tighten adjuster piece fully home (SOLID)

locating thrust cup onto ball pin.

6. Still with tool located on adjuster piece, back

off carefully (LEAST AMOUNT) until

adjuster piece split pin is allowed to pass

through body, and that ball pin shank can be

moved by moved of hand, then remove tool.

NOTE: If ball pin does not rotate when re-

adjusted in line with above instructions, this

suggests that ball pin has local worn flats. In this

instance ball pin, thrust cup and rubbing pad

MUST be replaced, if not FAILURE could occur

in service, i.e. ball pin not being able to move in

assembly when turning from lock to lock.

7. Fit cover plate into top of ball joint body, re-

peen using a cold chisel to secure.

8. Screw assembled ball joint onto tie rod.

Lining up marks on both body and tie rod

previously made, or retracking using manual

instructions.

9. Fit pinch bolts and nuts then tighten nuts

alternately and progressively thus securing

ball joint to tie rod.

TORQUE: 85-103 lb-ft (115-140 Nm)

10. Fit dirt seal (pressing) and dirt seal (rubber)

onto ball pin.

11. Locate ball joint and tie rod assembly with

lever, carefully align and fit ball pin into hole

in tie rod arm.

NOTE: Ball pin and ball pin tapers in bottom tie

rod arms must be clean, dry and free from oil

prior to assembly.

12. Fit pin washer onto ball pin.

13. Screw pin nut onto ball pin then tighten.

TORQUE:175-200 lb-ft (237-271 Nm)

14. Using a 2lb hammer, tap tie rod arm to

"shock' ball pin into taper hole.

15. Re-torque pin nut

TORQUE:175-200 lb-ft (237-271 Nm)

16. Fit split pin, if slot/hole are not in line, adjust

up to next slot.

17. Re-charge ball joint with Shell “Retinax LX”

or equivalent grease through grease fitting.

13.10 STRAIGHT BODY TYPE BALL JOINT

FIGURE 31: STRAIGHT BODY TYPE BALL JOINT

13.10.1 Visual Inspection

Visually inspect for missing or damages

grease fittings and replace if required.

Damaged sealing boot or improper sealing

requires seal replacement.

Check ball joint connection for missing

cotter pins.

Check for looseness in the ball/socket

assembly.

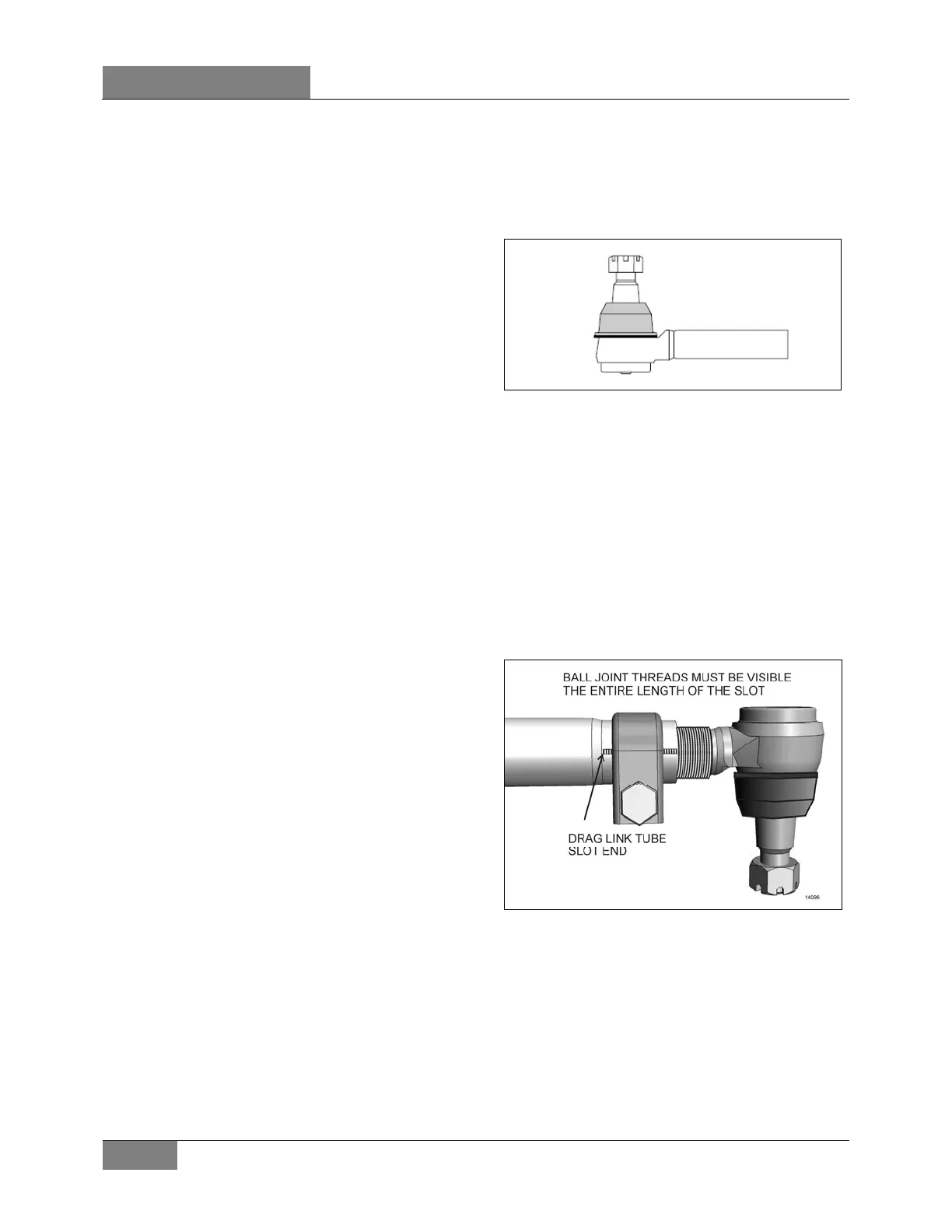

FIGURE 32: ADEQUATE CLAMPING CONDITION

For adequate clamping, the ball joint threads

must be visible the entire length of the tube slot.

If not, the drag link must be adjusted or

replaced. It is either the wrong size, or improper

adjustment was used to compensate for another

problem (e.g. bent steering arm).

Loading...

Loading...