SECTION 14: STEERING

22

PA1621 Maintenance Manual All Series | January 2017

MAINTENANCE

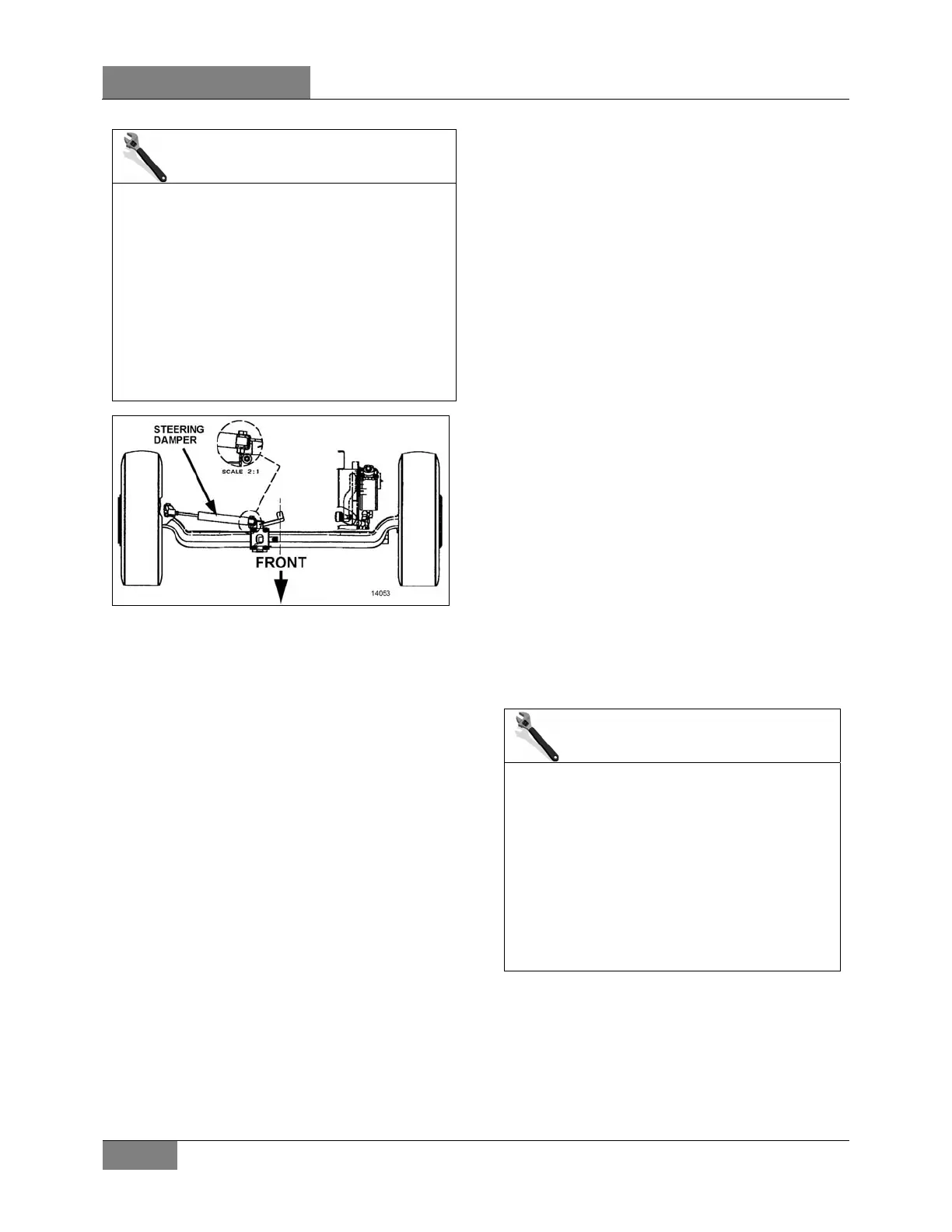

Steering damper ball joint (rod end) is provided

with grease fitting for pressure lubrication. Under

normal conditions, it should be serviced at the

intervals specified by the Lubrication And

Servicing Schedule in Section 24:

LUBRICATION & SERVICING.

Check the ball joint for wear, and replace if

necessary. Good quality lithium-base grease

NLGI No. 2 like Shell Retinax LX is

recommended.

FIGURE 26: STEERING STABILIZER (DAMPER)

13.6 DRAG LINK MAINTENANCE

Visually inspect drag link components for

broken, corroded or deformed clamps, loose,

bent or corroded nuts and gauges on tube from

rubbing parts.

13.6.1 IFS Drag Link

Lubrication Fittings

All lubrication fittings must be clean before

applying lubricant. Also, always be sure

equipment used in applying lubricant is clean.

Every precaution should be taken to prevent

entry of dirt, grit, lint or other foreign matter into

lubricant containers. Replace fitting when

become broken or damaged.

Re-charge ball joint until grease can be seen

escaping from socket. On ball joints fitted with a

rubber boot, do not add to much grease as the

rubber boot might expand and rupture.

In selecting proper lubricants, supplier

reputation must be considered. The supplier

must be responsible for product quality. Figure

27 shows approximate location of steering

lubrication fittings.

MAINTENANCE

Drag Link (with Independent Front

Suspension)

Drag link ends (ball joint) are provided with

grease fittings for pressure lubrication.

To prevent corrosion from forming around the

ball pin (particularly the drop type ball joint as

it is exposed to dirt and water), remove the

old grease bead and assure sufficient grease

is applied to purge the old grease and fill the

joint and dust seal.

Loading...

Loading...