SECTION 13: WHEELS, HUBS AND TIRES

20

PA1621 Maintenance Manual All Series | January 2017

No. 23A" annexed to Section 11 of this

manual.

2. Remove wheels and tires.

NOTE

It is good practice to mark position of the

wheel on the axle before removal and replace

wheel at the same position during

reinstallation.

3. Remove lock nut, lock ring and adjusting nut

from axle housing to prevent the outer

bearing from falling out. Remove outer

bearing cone and roller assembly.

4. Remove screws attaching inner oil seal

retainer to hub, and remove inner oil seal

assembly. Remove inner bearing cone and

roller assembly. Bearing cups can be

separated from the hub using a hammer and

a long brass drift.

5. Thoroughly clean all parts. Bearing cone and

roller assemblies can be cleaned in a

suitable cleaning solvent using a stiff brush to

remove old lubricant.

6. In case that excessive wear, deterioration,

cracking or pitting is present on the bearing

cups, rollers or cones, the bearings should

be replaced. Seals should be replaced each

time they are removed from the hub. To

install new oil seal, use a suitable adapter

and drive the seal into the retainer bore until

it bottoms.

7. When installing wheel on spindle, center the

wheel hub with spindle to avoid damaging

the seal with the end of the spindle. Push

wheel straight over the spindle until inside

diameter of seal press fits on wiper ring. Fill

hub cavity with general-purpose gear

lubricant (refer to Section 24 "Lubrication" for

proper oil grade selection). Lubricate, then

install outer bearing cone. Adjust bearing and

lock.

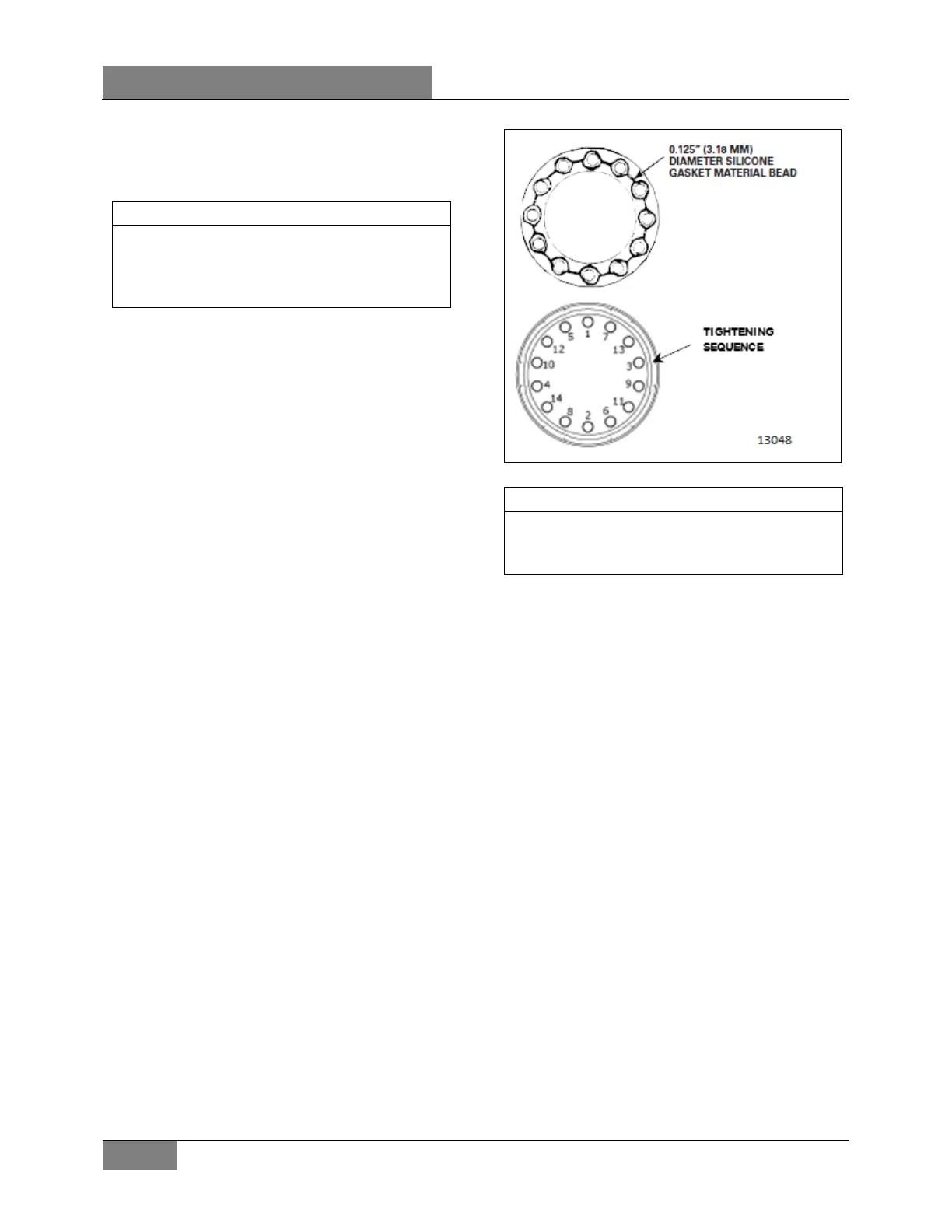

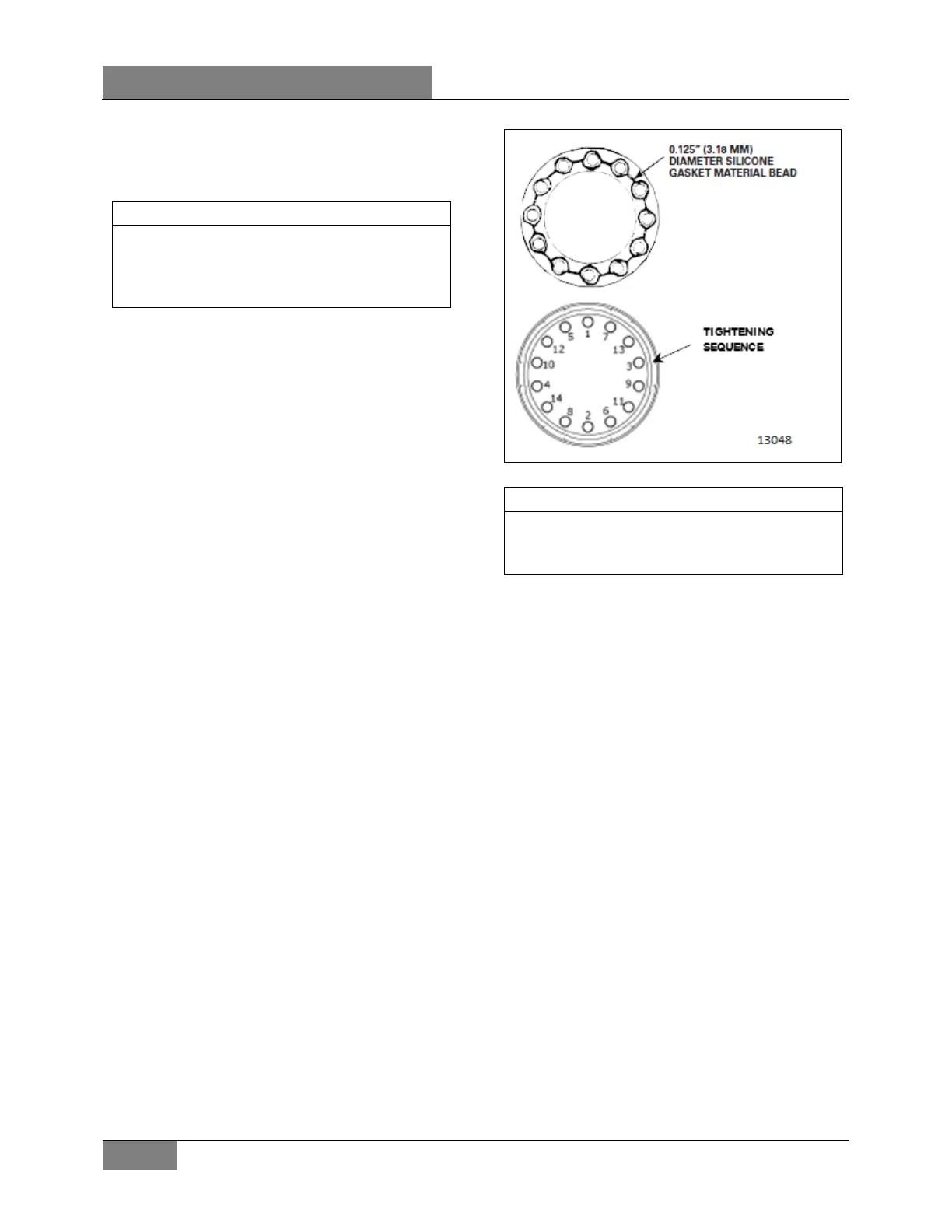

8. Assemble axle flange to axle using a new

gasket. Apply sealant in stud area. After both

wheels have been assembled according to

above procedure, fill the differential with the

recommended lubricant to the proper factory

recommended level.

FIGURE 26: AXLE FLANGE TIGHTENING SEQUENCE

NOTE

During regular inspection, do not forget to

check lubricant level in differential. Clean

thoroughly or replace vent as required.

12. ZF DRIVE AXLE WHEEL HUBS

The ZF A132 hypoid single reduction drive axle

hub (

FIGURE 27) is fitted with unitized bearing

known as compact bearing in ZF’s literature.

12.1 COMPACT BEARING (HUB UNIT) AXIAL

PLAY CHECK

Check the compact bearing (hub unit) axial play

at the intervals specified by the Lubrication And

Servicing Schedule in Section 24:

LUBRICATION & SERVICING. Furthermore, the

bearing must be checked in case of brake disk

change, ABS fault message and rising noise

level at increasing speed.

Perform compact bearing (hub unit) axial play

check as described in paragraph 6.2 HOW TO

CHECK THE AXIAL PLAY of the following

manual: OPERATING INSTRUCTIONS ZF

AXLE A132 (version with US hub) #5871

207 982 EN.

Loading...

Loading...