SECTION 14: STEERING

PA1621 Maintenance Manual All Series | January 2017

25

2. Use an appropriate inspection tool (e.g.

spatula with cut out) to push up (sealing

boot) or down (dirt seal) the seal (without

damaging it) until ball pin surface is visible.

Degrease the ball pin surface and inspect

carefully.

3. If there is corrosion of the ball pin or the

sealing boot has deteriorated through

ageing or is damaged, replace the ball joint.

4. If there is corrosion of the steering arm or tie

rod arm area which is in contact with the

sealing boot or dirt seal, clean and eliminate

all surface irregularities.

5. If there is no corrosion or damage to the

sealing boot or dirt seal, smear the steering

arm and tie rod arm with Lithium grease and

push seal back into its properly seated

position.

When dismantling tie rod or drag link, ensure

that no damage is caused to the sealing boots,

dirt seals or ball joint housings.

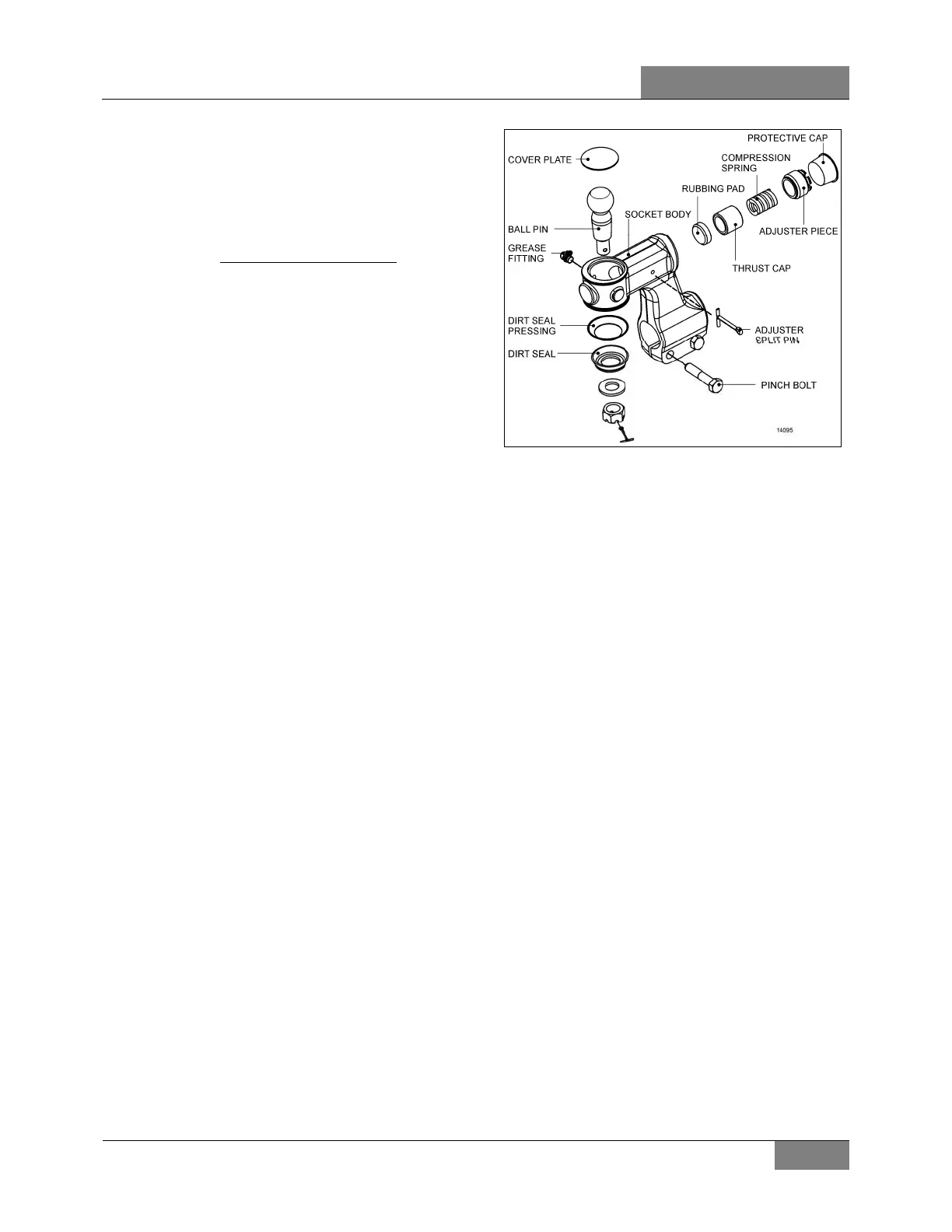

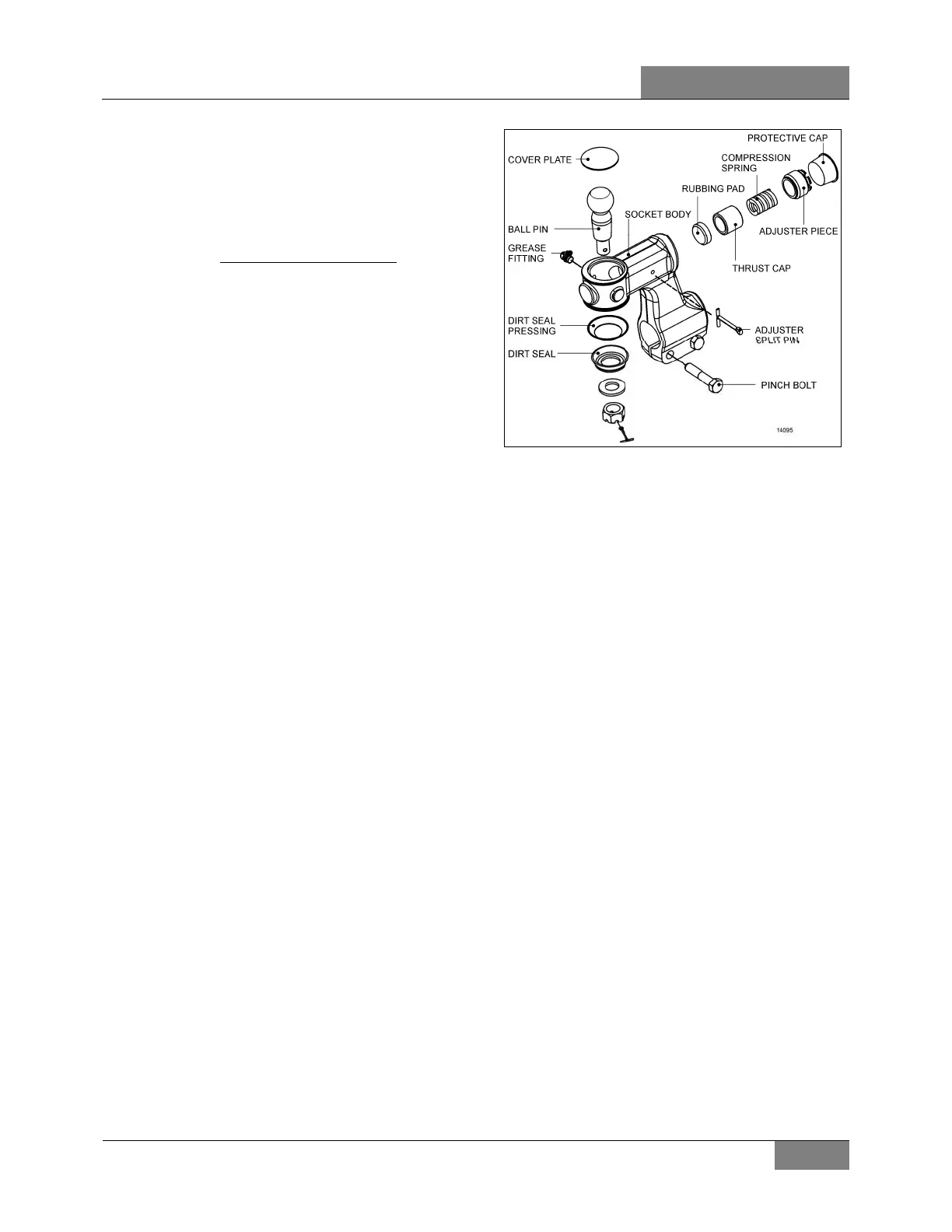

13.9 DROP TYPE BALL JOINT

13.9.1 Drop Type Ball Joint End Play

If end play (direction of the ball pin axis)

exceeds 0.047” (1.2 mm), readjustment is

necessary.

Remove protective cap, using a suitable tool i.e.:

a 1” x 1/8” x 9” long flat bar, tighten adjuster

piece fully home (SOLID) locating thrust cup

onto ball pin.

Still with tool located on adjuster piece, back off

carefully (LEAST AMOUNT) until adjuster piece

cotter pin is allowed to pass through body, then

remove tool.

Reinstall protective cap.

FIGURE 30: DROP TYPE BALL JOINT FOUND ON TIE

ROD (2X)

13.9.2 Dismantling Drop Type Ball Joint

1. Remove dirt seal and dirt seal pressing from

ball pin.

2. Slacken pinch bolt nut then unscrew and

remove ball joint assembly from tie rod

having first marked ball joint body and tie rod

to enable tracking on re-assembly.

3. Remove adjuster split pin from ball joint

body.

4. Remove cap then using a suitable tool i.e.: a

piece or 1”x1/8”x 9” flat bar, unscrew and

remove adjuster piece. Waggle ball pin to

free thrust cap.

5. Remove compression spring and thrust cap

from ball joint body.

6. Relieve peening on socket body top then

using a hide faced mallet, tap ball pin out of

body. This operation will also remove cover

plate from body.

7. The rubbing pad can now be removed from

body.

Thoroughly clean all parts and check for

wear, renewing where necessary.

13.9.3 Assembling Drop Type Ball Joint

1. Apply a bead of Loctite 638 sealant to

mating corner of rubbing pad in socket body

then knock rubbing pad into its recess in ball

joint body.

Loading...

Loading...