SECTION 22: HEATING AND AIR CONDITIONING

66

PA1621 Maintenance Manual All Series | Section Revised November 2017

4. Shut down the vacuum pump.

5. Check to insure that vacuum holds. (If the

pressure continues to rise, it indicates a

leak or moisture in the system).

6. Charge the system with the proper amount

of refrigerant through the service port near

the check valve using recommended

charging procedures.

7. Remove the hoses.

7.7 OIL ADDITION

The chart below shows the approximate amount

of oil to be added to the system when replacing

a component.

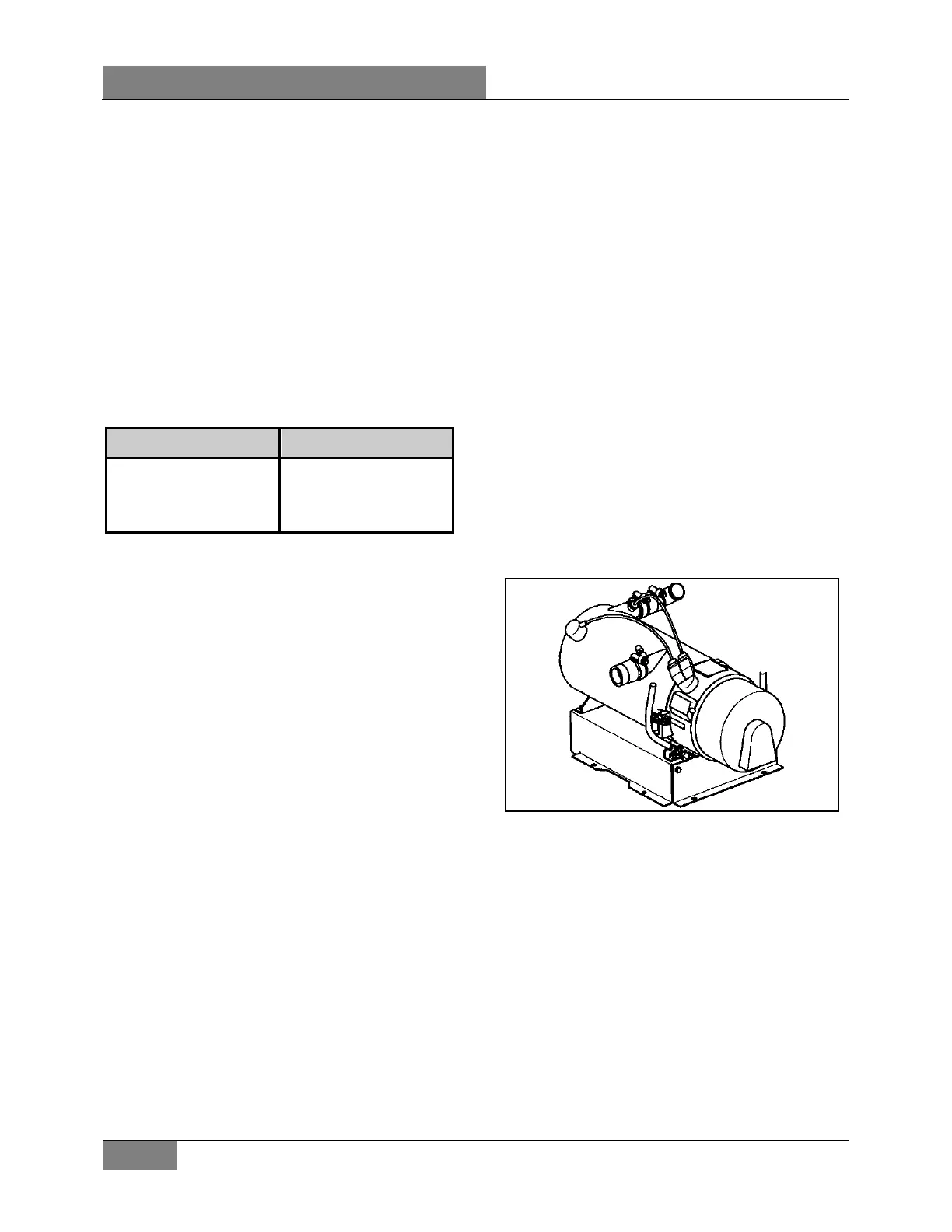

Component replaced Typical amount of oil

Evaporator

Condenser

Filter-Dryer

50 ml (1.7 ozs)

30 ml (1.0 ozs)

10 ml (0.3 ozs)

The amount of oil recovered with the refrigerant

recovery should be added at the same time.

7.8 COMPRESSOR OIL CONTAMINATION

Unlike engine oil, no cleaning agent is added to

the compressor oil. Even if the compressor is

run for a long time, the oil never becomes turbid

as long as there is nothing wrong with the

compressor or its method of use. Inspect the

extracted oil for any of the following conditions:

Dirt in the oil.

Change to a varnish color.

Presence of foreign substance, metal

shavings, etc. in the oil. When the oil

extracted from the compressor is as

described above, replace the oil as follows:

1. Clean the interior of the system with

approved method.

2. Replace the filter-dryer.

3. Supply with new oil as specified in small

Compressor Service Manual included at

the end of this section

7.9 OIL RETURN OPERATION

There is a close affinity between oil and

refrigerant. During normal operation, part of the

oil recirculates with the refrigerant in the system.

Therefore, when checking the amount of oil in

the system or replacing any system component,

the compressor must be run in advance to

ensure return. This procedure is as follows:

If the amount of refrigerant in the system has

decreased, charge to the proper amount.

Start the engine and select fast idle.

Set the fan speed to full air/full A/C and let

run for 20 minutes.

8. PREHEATING SYSTEM (OPTION)

This Auxiliary Preheating System is used for

preheating and retaining the heat of water-

cooled engines. It can be used before starting

the engine to ease its starting and to provide

immediate inside heat upon operation of the

heating system. It can also be used with engine

running to maintain coolant heat and maintain

the set temperature inside vehicle.

The preheater operates independently from the

vehicle engine. It is connected to the cooling and

heating circuits, the fuel system and the

electrical system of the vehicle.

FIGURE 84: PREHEATER (104,000 BTU) 22224

The pilot lamp turns on when the preheater is

switched on. Combustion air flows in to flush out

the combustion chamber and the water

circulation pump is put into operation. The fuel

metering pump conveys fuel in precise doses to

the combustion chamber where fuel and

combustion air form a combustible mixture

which is ignited by the glow plug.

Once the flame sensor has signaled to the

control unit that combustion has taken place

correctly, the glow spark plug and ignition coil

are switched off.

The hot combustion gases are diverted at the

end of the flame pipe, then pass through the

indirect heating surfaces of the heat exchanger

Loading...

Loading...