PA1621 Maintenance Manual All Series | January 2017

Idler arm: Remove cotter pins and nuts from

ball studs connecting relay rod, tie rod and

hydraulic power cylinder to idler arm. Separate

socket assemblies from idler arm.

Remove nuts from bolts attaching bell crank or

idler arm mounting spindle to vehicle subframe.

Remove bell crank or idler arm mounting

spindle.

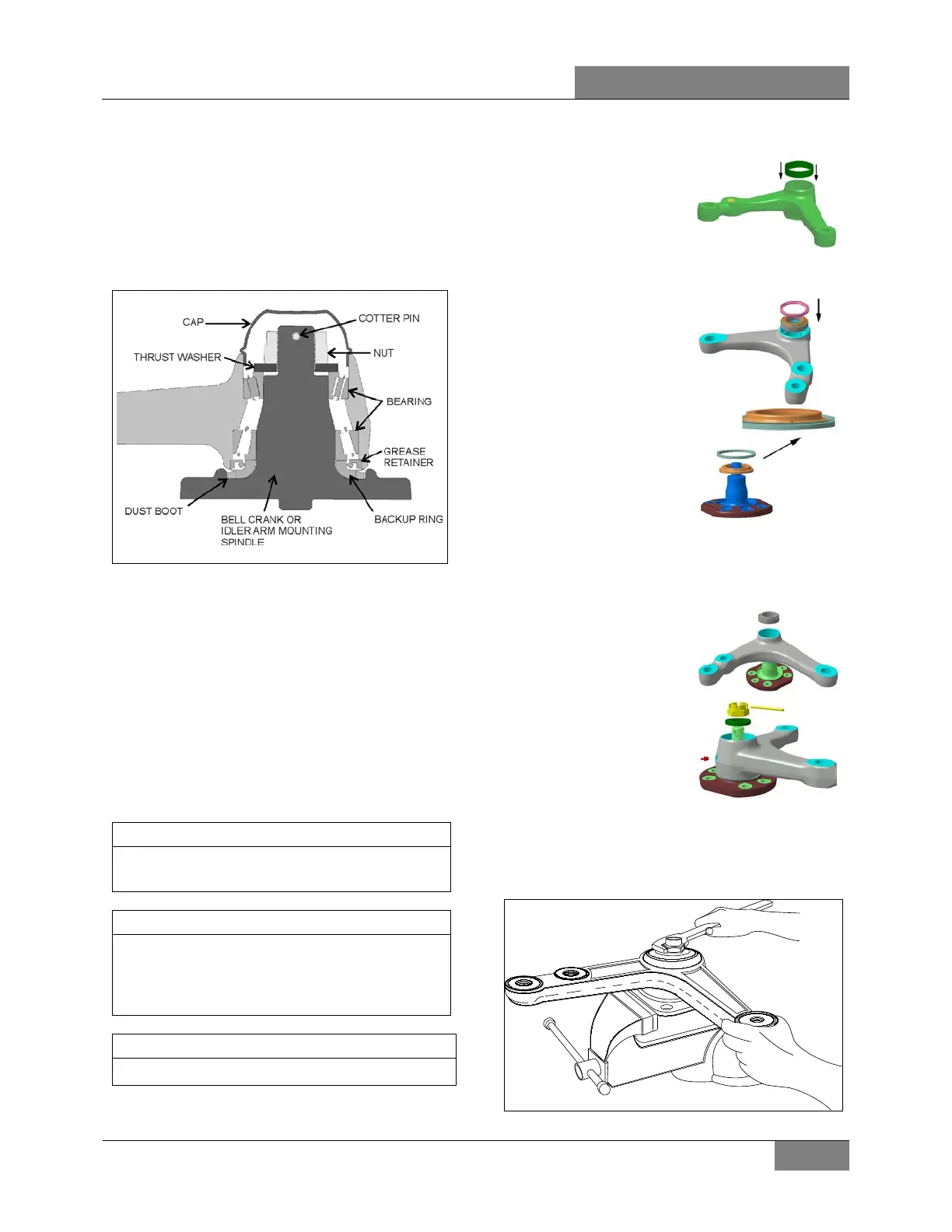

FIGURE 14: BELL CRANK OR IDLER ARM HUB

4.5.2 Bell crank or Idler Arm Hub Disassembly

1. Remove adjacent link assemblies from bell

crank or idler arm as previously described.

2. Remove the cap (Figure 14).

3. Remove the cotter pin, nut and thrust

washer. Remove bearings, grease retainer,

backup ring and the bell crank or idler arm

from its mounting spindle (Figure 14).

4.5.3 Bell Crank or Idler Arm Hub Reassembly

For bearing installation use tool Prevost #

110684.

Install grease retainer according to Figure 14.

Grease must be able to exit the bell crank or

idler arm mechanism. For grease retainer

installation use tool Prevost # 110683.

Apply grease on bearings before installation.

1. Clean parts thoroughly with degreaser.

2.

bearing o

uter race

into appropriate

bore (done on a

3.

Insert the large bearing outer race into

appropriate bore (done on a press).

4.

bearing into outer

race and then, add

grease retainer.

5.

Apply good quality

lithium grease

(#680752) on

backup ring and

dust boot.

6. Install backup ring and dust boot on bell

crank or idler arm spindle.

7.

Apply a thin layer of grease on spindle

shaft.

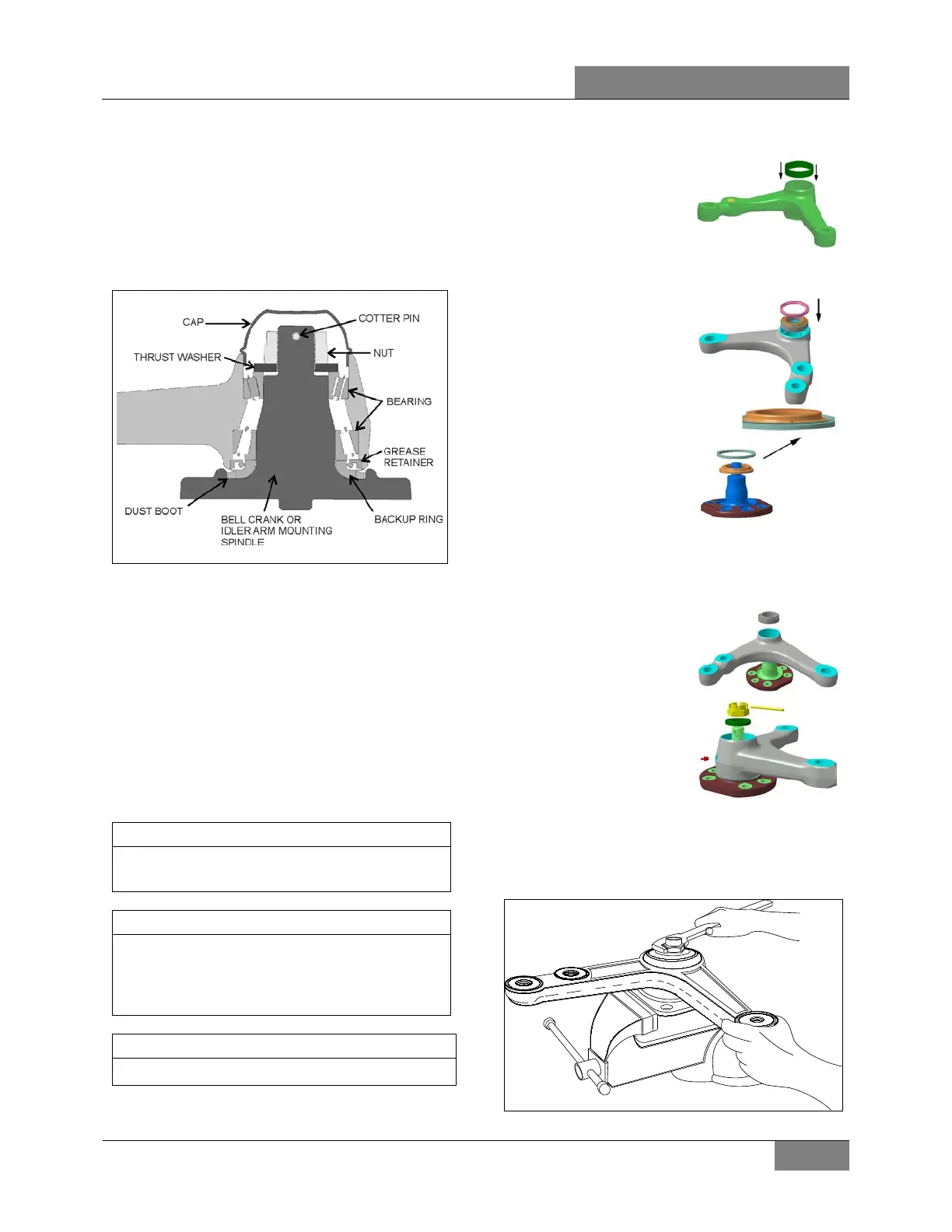

8. Install bell crank or

mounting spindle,

while holding the

bell crank or idler

arm, slide on the

small bearing

assembly, thrust

washer and secure

using nut.

9. Tighten nut.

TORQUE:130 lb-ft (176 Nm)

10. Rotate assembly 3 turns in each direction.

FIGURE 15: BELL CRANK 16044

Loading...

Loading...