SECTION 22: HEATING AND AIR CONDITIONING

PA1621 Maintenance Manual All Series | Section Revised November 2017

47

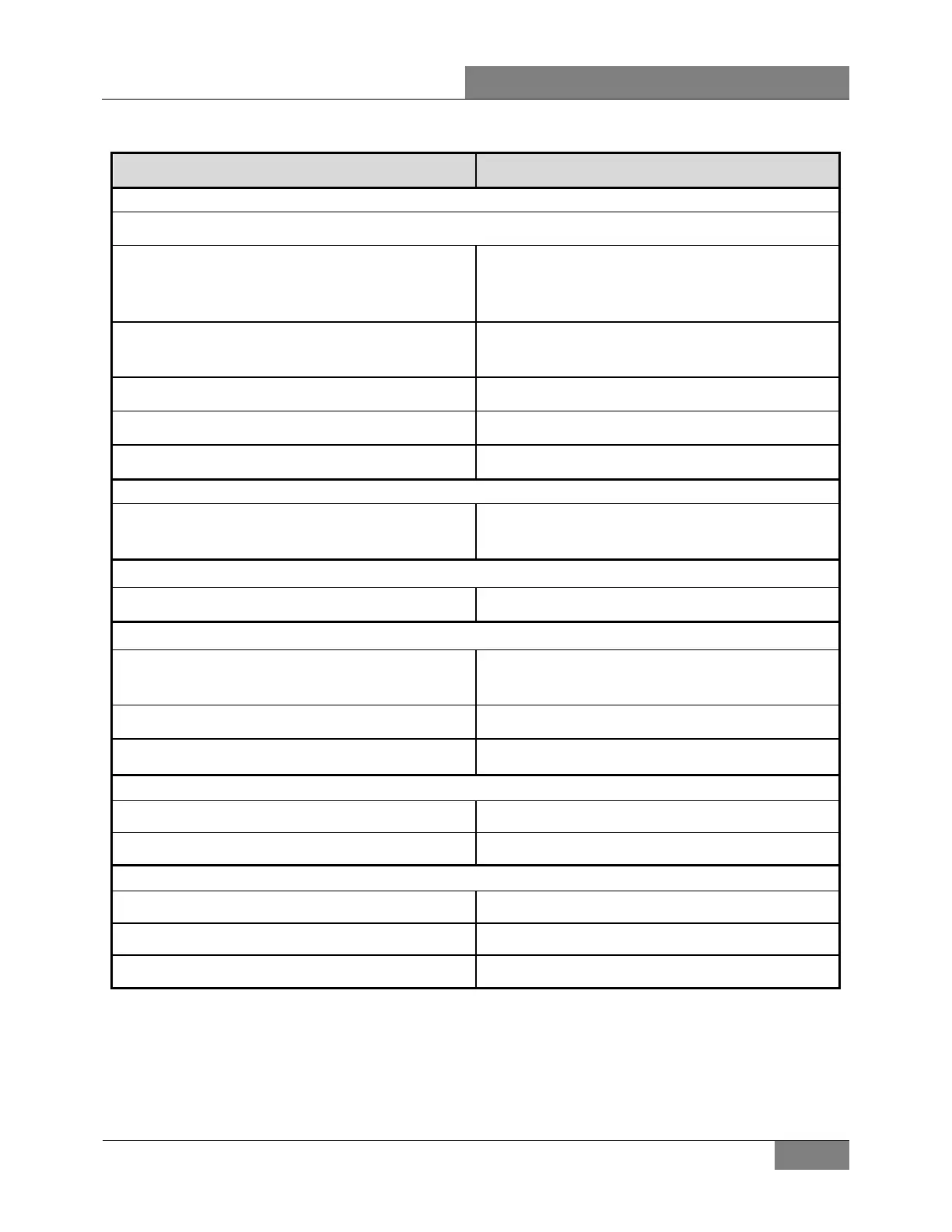

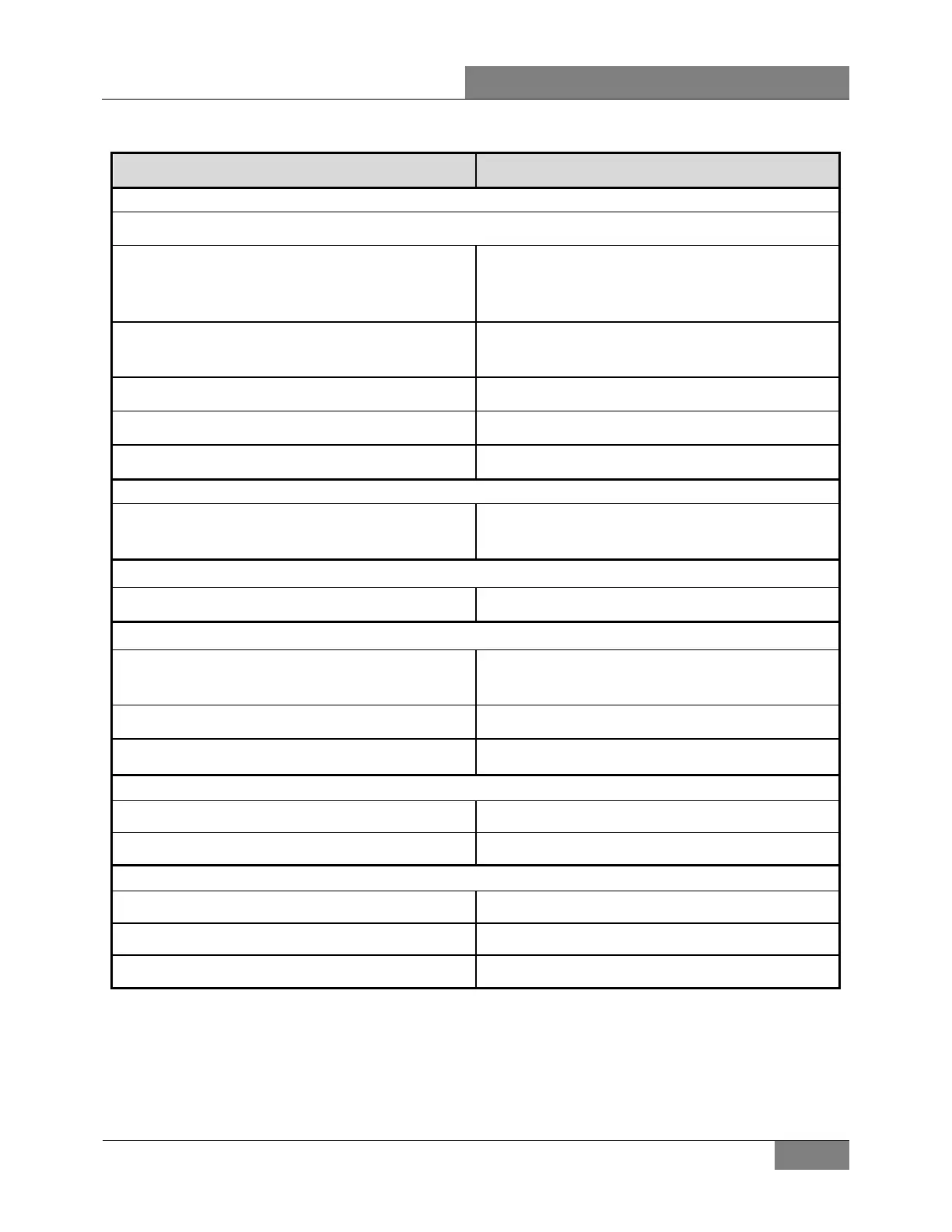

5.7.2 Expansion Valve

PROBABLE CAUSE PROBABLE REMEDY

LOW SUCTION PRESSURE-HIGH SUPERHEAT

EXPANSION VALVE LIMITING FLOW:

Gas in liquid line due to pressure drop in the line

or insufficient refrigerant charge.

Locate cause of line flash and correct by use of

any of the following methods. Add R-134a.

Replace filter-dryer.

Superheat adjustment too high. Adjust superheat as outlined under "Superheat

Adjustment".

Power assembly failure or partial loss of charge. Replace expansion valve.

Air filter screen clogged. Clean or replace air filter screen.

Plugged / kinked / chaffed lines. Clean, repair or replace lines.

LOW SUCTION PRESSURE-LOW SUPERHEAT

Uneven or inadequate evaporator loading due to

poor air distribution or liquid flow.

Balance evaporator load distribution by providing

correct air or liquid distribution.

HIGH SUCTION PRESSURE-HIGH SUPERHEAT

Internally leaking compressor Locate leak. Repair/ replace.

HIGH SUCTION PRESSURE-LOW SUPERHEAT (DEFECTIVE UNLOADER)

Valve superheat setting too low. Adjust superheat as outlined under "Superheat

Adjustment".

Compressor discharge valves leaking. Replace or repair discharge valve.

Incorrect superheat adjustment.

Superheat adjustment 12 to 16F.

FLUCTUATING DISCHARGE PRESSURE

Insufficient charge. Add R-134a to system.

HIGH DISCHARGE PRESSURE

Air or non-condensable gases in condenser. Purge and recharge system.

Overcharge or refrigerant. Recover to proper charge.

Condenser dirty. Clean condenser.

Loading...

Loading...