PowerMeasuringModule PMM

35,0(

14

Revision 13 EN - 02/2023

4.2 Functional description

The PMM is used to measure laser power. After opening the shutter, the laser beam hits the absorber and

scattering light is registered by a photodiode. The absorber and the photodiode are protected from contami-

nation by the protective window. The shutter and the caps on the ports protect the PMM from contamina-

tion. Thus, the PMM can be used directly in the production environment in the process zone.

The PMM operates without cooling water and compressed air. The absorber cools off only through thermal

conduction to the ambient air.

Thanks to the availability of various fieldbus interfaces, the PMM can be integrated in nearly every existing

machine. The measurement results are transferred directly to the PLC.

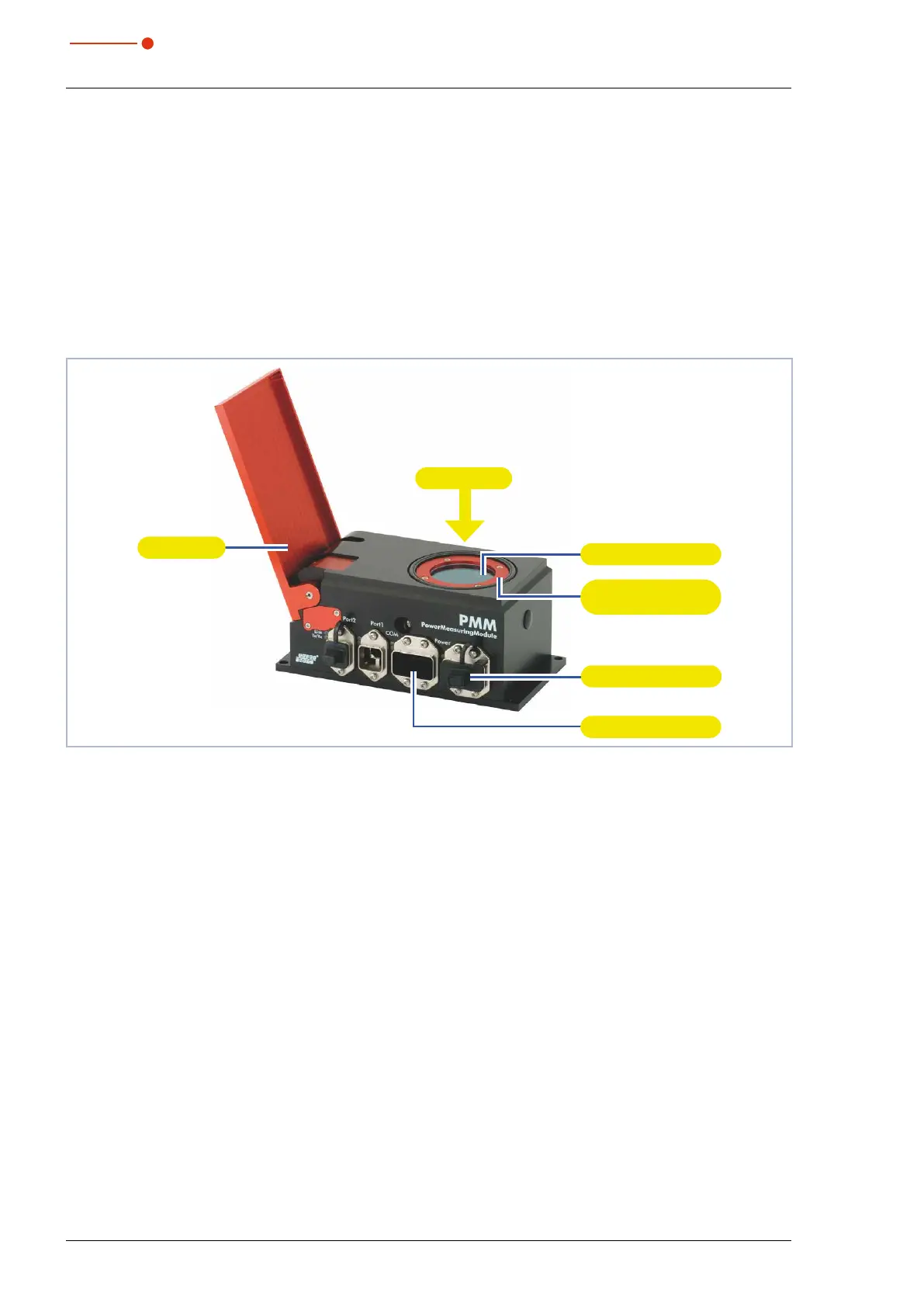

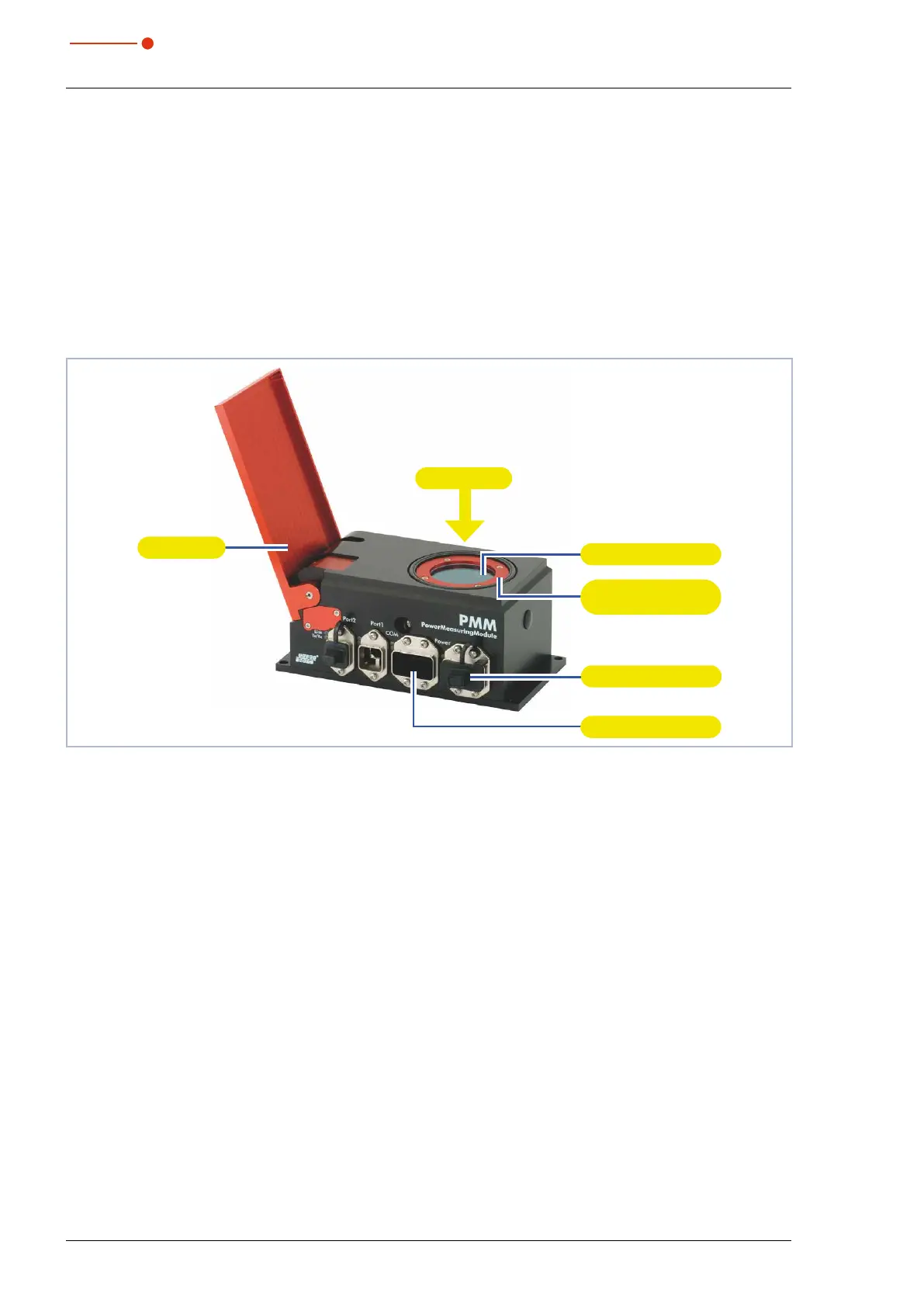

Laser beam

Protective window

mount

Port

Protective window

Cover caps

Shutter

Fig. 4.2: PMM with open shutter using the example of PMM PROFINET

®

4.3 Measuring principle

The PMM offers a fast, passively cooled power measurement according to the calorimetric measuring prin-

ciple. The absorber of the measuring device is briefly irradiated with the laser beam. The irradiated energy is

determined by the temperature rise of the absorber.

The photodiode simultaneously determines the laser ontime. The high-frequency sampling rate of the

photodiode enables single pulse detection for pulses not shorter than 50μs.

Thus, in addition to the average power, the peak power can also be calculated. In the second step, the ac-

tual laser power is calculated from the absorbed energy divided by the laser ontime.

Loading...

Loading...