Page 53

Example 2 Level Monitoring and Control (up or down)

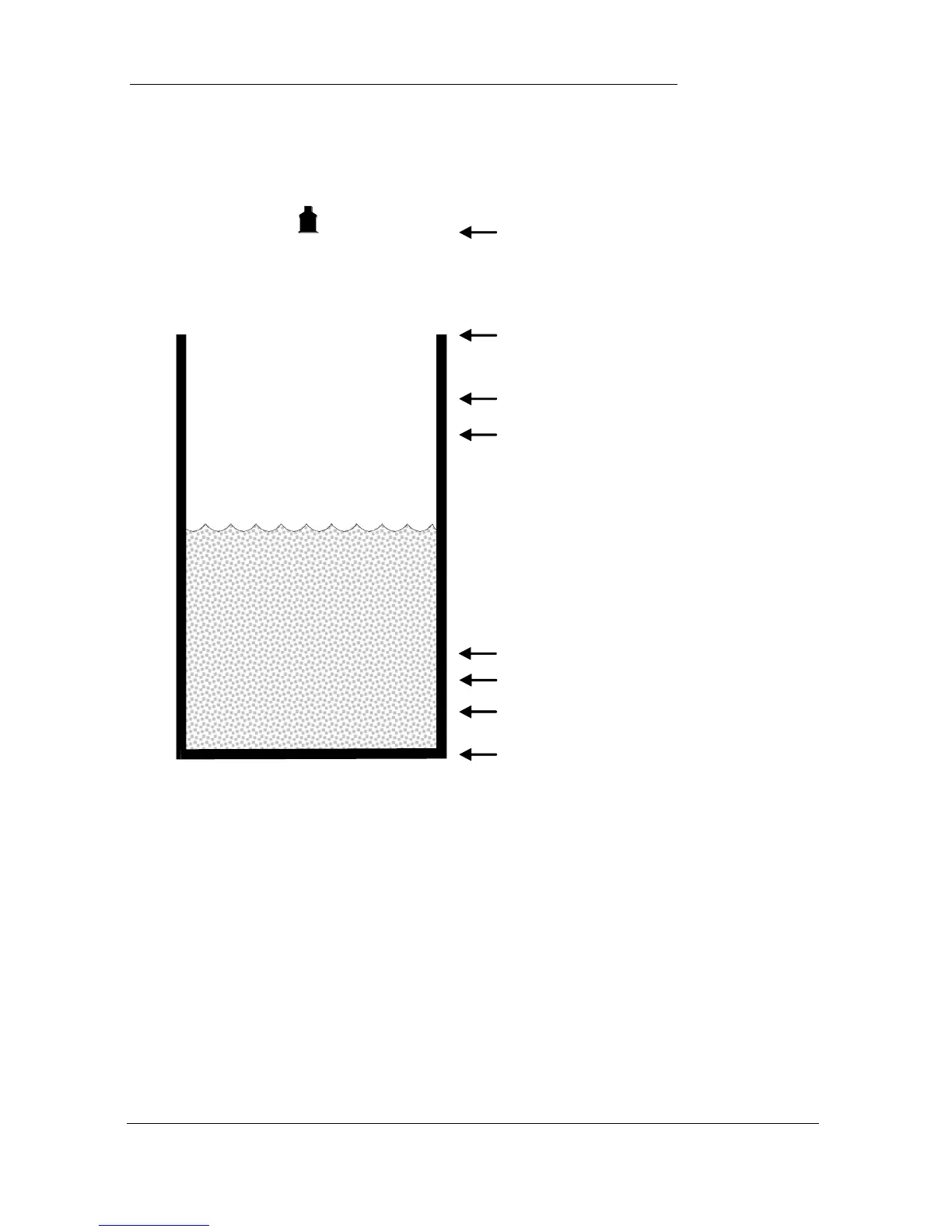

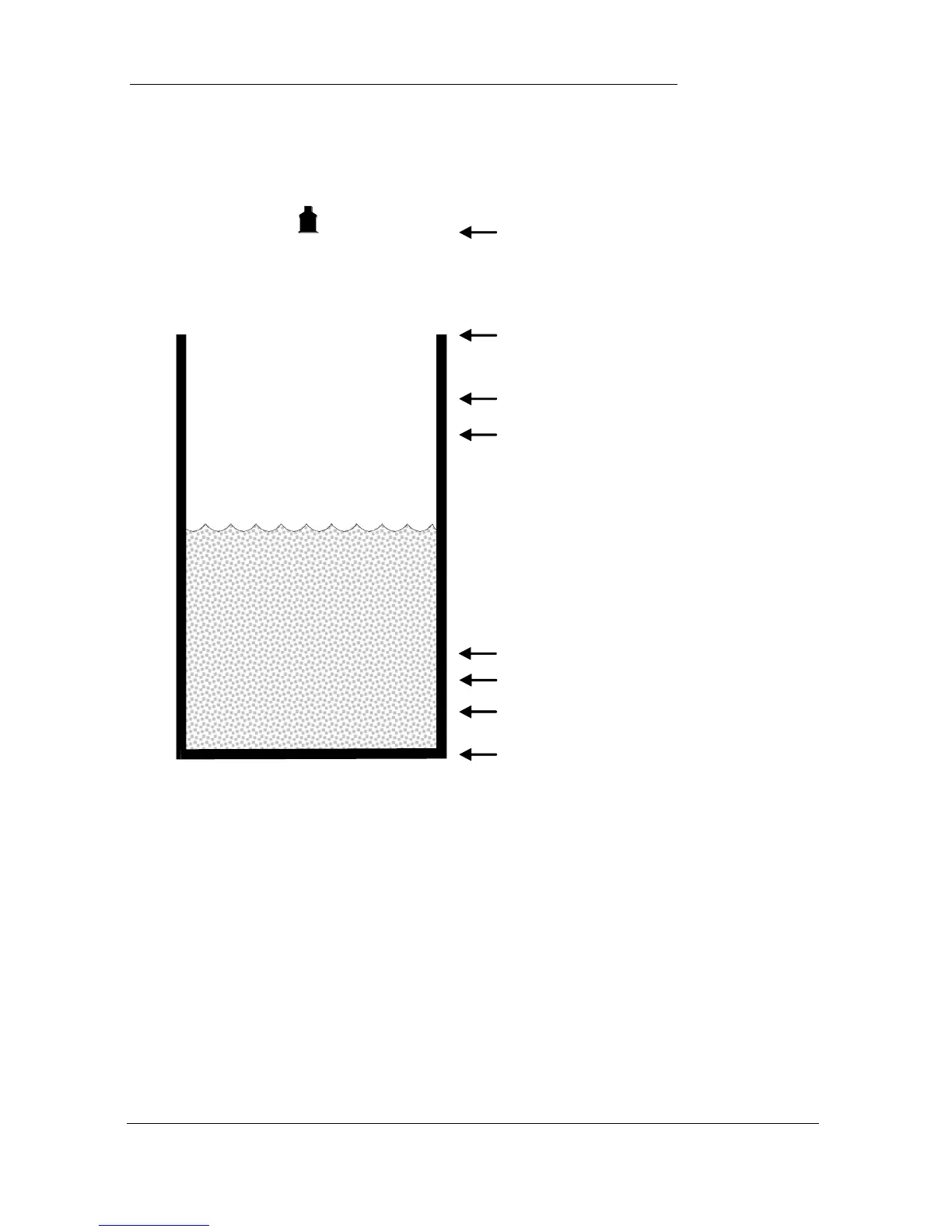

A vessel, containing a liquid that has a variation in level that is to be

monitored, and when the level reaches a specific point, the vessel is pumped

down, with the fluid being transferred to another process. The pump will be

assigned to Relay 1 a High Alarm to Relay 2 and Low Alarm to Relay 5.

empty distance (P105), 3.5m

85%, high alarm on (P223), 2.38m

80%, high alarm off (P224), 2.24m

80%, control (down) on (P213), 2.24m

15% , low alarm off (P254), 0.42m

10%, low alarm on (P253), 0.28m

20%, control (down) off (P214), 0.7m

In this example, there is a pump (relay 1), which will come on if the level

rises to 2.24 m, and go off when the level drops to 0.7 m. (control down). If

the level rises to 2.4 m, then the high-level alarm (relay 2) will come on

until the level drops to 2.24 m. If the level falls to 0.28m, then the low-level

alarm (relay 5) will come on until the level rises to 0.42 m.

Alternatively, if it is a control up application, then the on and off points for

the control relay are reversed, so the control relay comes on when the level

is at 0.7 m and goes off when it rises to 2.24 m.

The display will show the level in the tank and the mA output will be

representative of level where 4mA = empty level (0%) and 20mA = 2.8m

(100%).

Loading...

Loading...