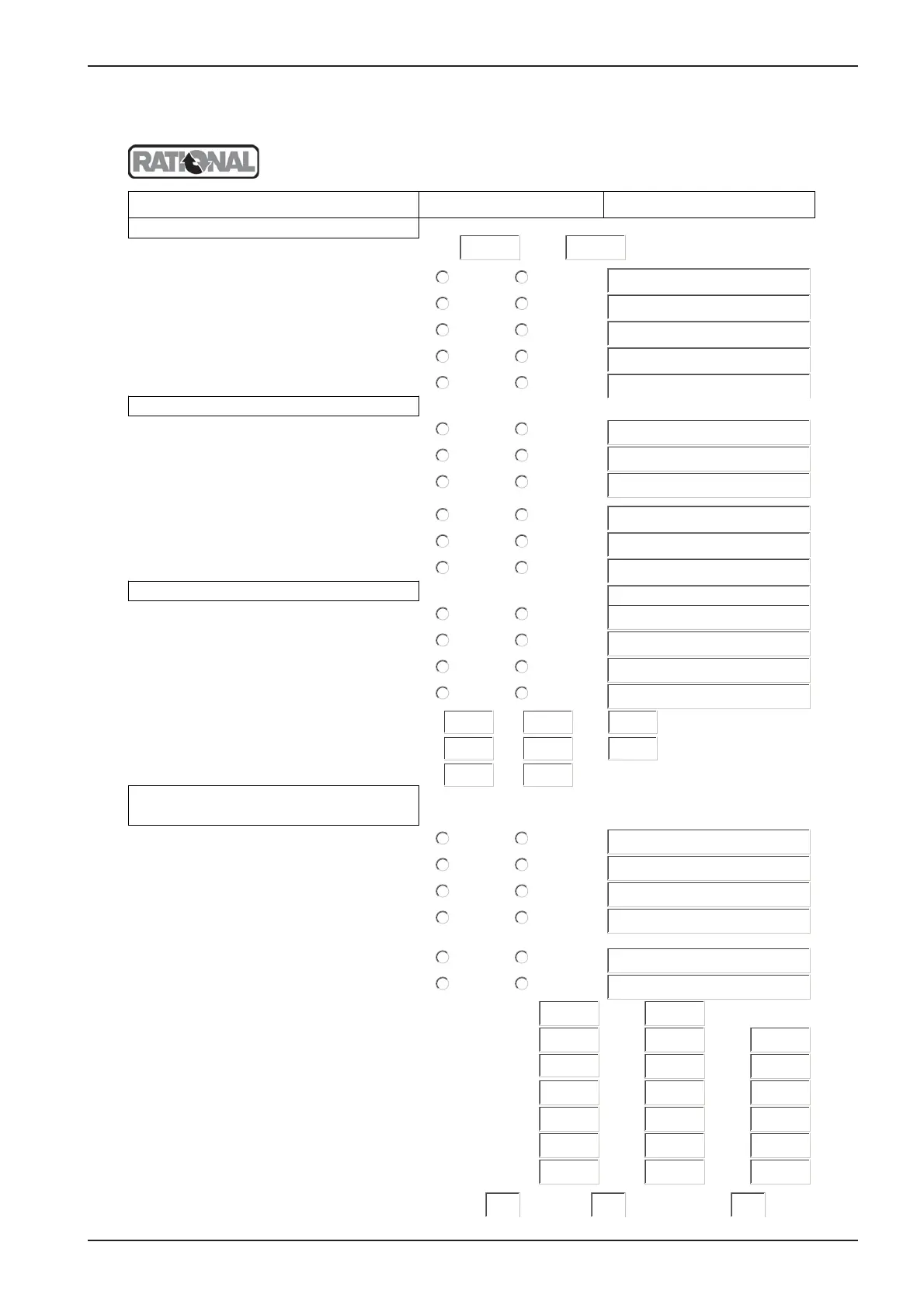

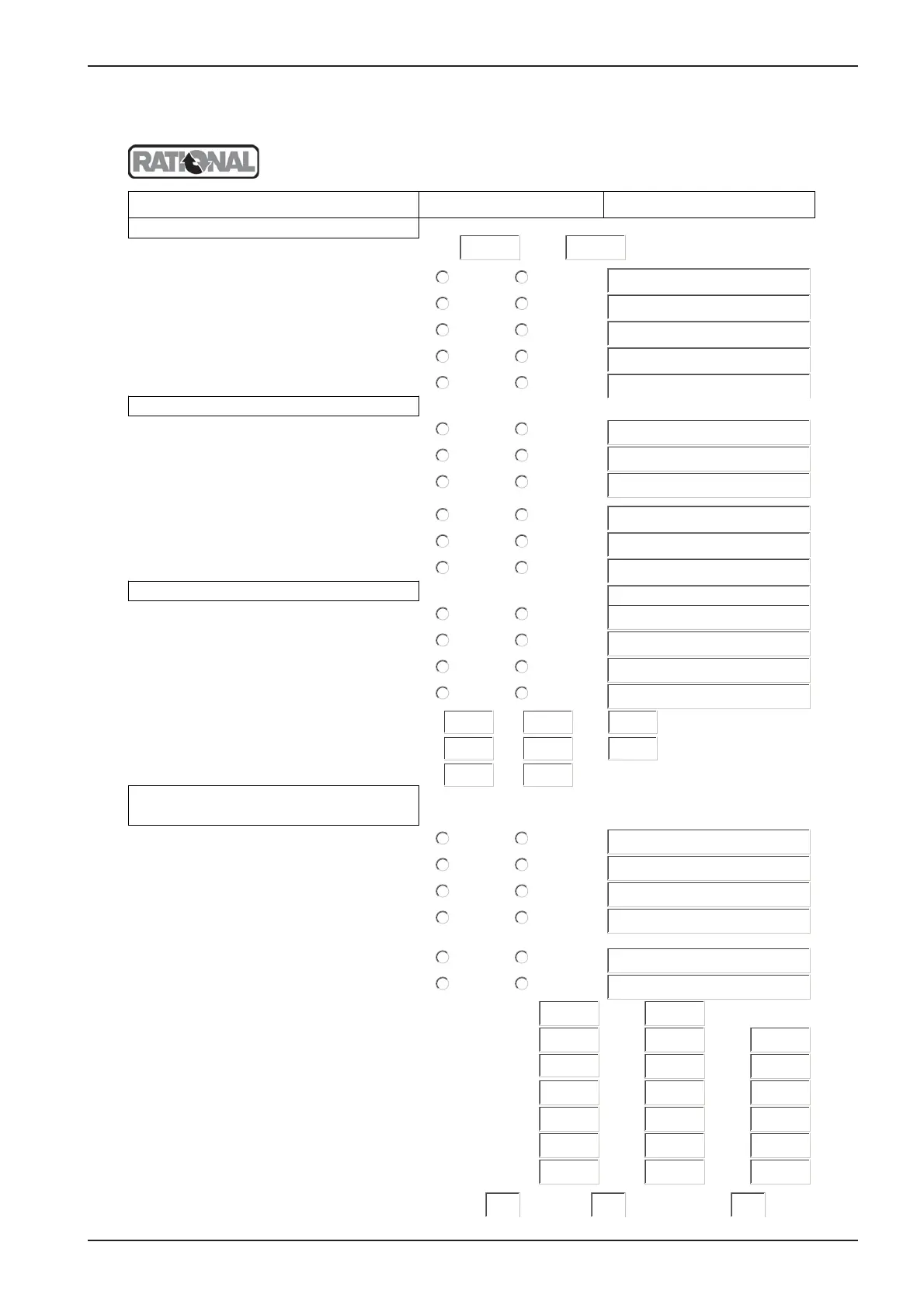

151

Common Information

Edition 10-2008a

Preventative maintenance

NO

OK

YES

NO

YES

NO

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

YES

NO

NO

YES

NO

YES

NO

YES

NOYES

NO

YES

Dynamic water pressure

INSPECTION LIST SCC / CM

Water - Drain

Comments:

All water connections leak tight

Hand shower and retracting mechanism

Drain connection

Quenching - drain box clean

Drain valve SCC

Steam generator

Leak tight

Steam generator pump - flushing

Descale steam generator if needed

Level electrode clean

Electrical components

Earth bonding

All wires tightly secured

All contacts of main contactor free (not stuck)

Amp draw - Hot Air

Amp draw - Steam

Max temperature pcb

Gas specific parts

NOTE: Yearly burner maintenance needed!

Cleaning of burner head (TI 03-2007)

Burner blower ok and free of dust / fat residues

Dynamic flow pressure (unit in operation)

CO2 max steam - flame current - CO ppm

CO2 min steam - flame current - CO ppm

CO2 max hot air top - flame current - CO ppm

CO2 min hot air top - flame current - CO ppm

Visual inspection of external flue gas venting

L1 L2 L3

L1

L2

L3

°C

mbar kPa

% μA

μA

μA

%

%

% μA

ppm

ppm

ppm

ppm

YES

NO

YES

NO

Cleaning of ignition electrode

Change blower gasket Steam and Hot Air

if damaged

Lenght of CO2 screw of gas valve in mm

Hot air bottomHot air topSteam

Preventative Maintenance Work Scope:

Edition 09/2007, page 2/3

NO

YES

Reset CDS indication

°F

Function

bar kPa

NO

YES

NO

YES

YES

NO

Insulation steam generator ok

All wire insulation undamaged

All gas connections leak tight

CO2 max hot air bottom - flame current - CO ppm

CO2 min hot air bottom - flame current - CO ppm

μA%

% μA

ppm

ppm

Loading...

Loading...