152

Common Information

Edition 10-2008a

Preventative maintenance

Edition 09/2007, page 3/3

NO

YES

YES

NO

YES

NO

YES

NO

YES

NO

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

YES

NO

Control panel closing mechanism

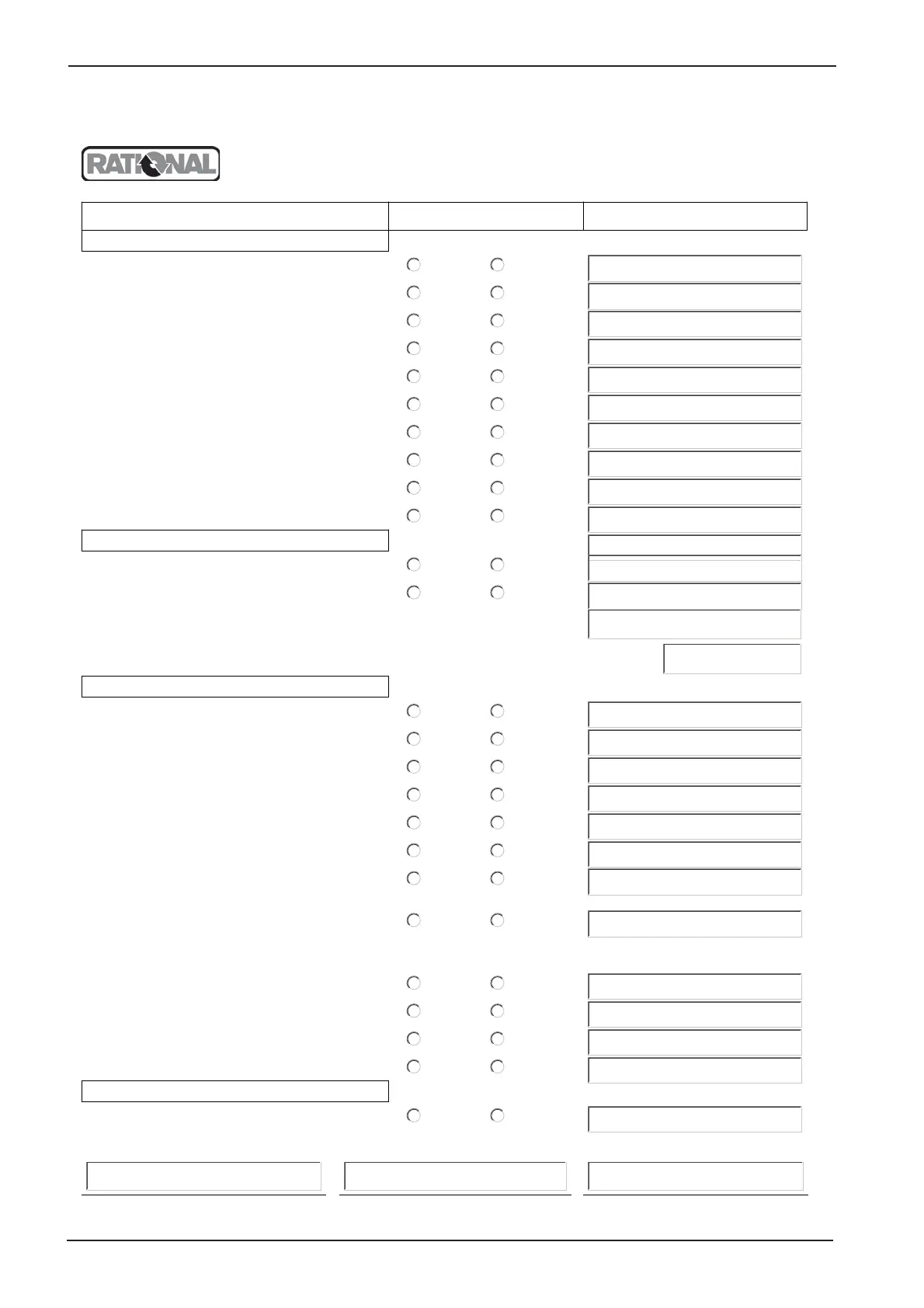

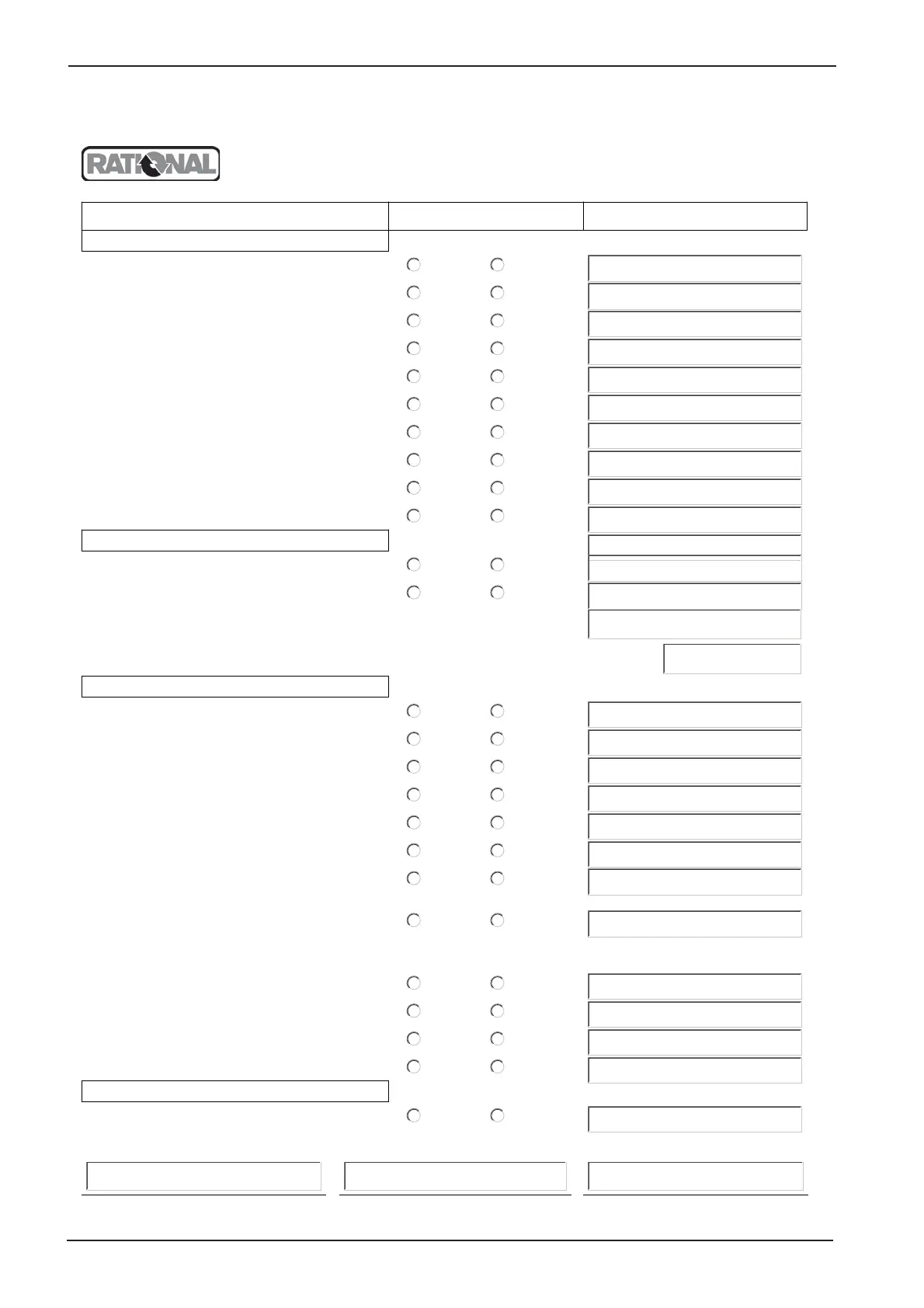

INSPECTION LIST SCC / CM

Function

Control panel

Comments:

Control panel gasket and panel overlay

Plug for opening control panel in place

Dials

Mode switch (CM)

Temperature and time control

Core probe function

LED indicators

PCB visual check (water marks etc)

Exhaust / Vent hood

Function test / commissioning

All electrical connections and plugs tight

Service phone number entered

Chef line phone number entered

Demonstration CleanJet

Electrical safety test

Electrical safety tested according local codes

Serial number Rational UltraVent - Rational exhaust hood

Free space between top egde of unit and lower edge of exhaust hood / ceiling in cm

Exhaust / vent hood installed

All modes operational

All valid service error codes checked

Customer advised in basic operation

and Programming

Customer advised in preventative maintenance

(descaling, changing air inlet filter,

door gasket cleaning, etc)

Technician : Date and signature Customer : Date and signature

Preventative Maintenance Work Scope:

YES

NO

NO

YES

Safe Service data - HACCP data to usb stick

Air filter clean

RSP : Name

NO

YES

NO

YES

YES

NO

NO

YES

Exhaust hood / lighting operational

All electrical connections and plugs tight

All max values of sensors resetted

Humidity control functional

Loading...

Loading...