2

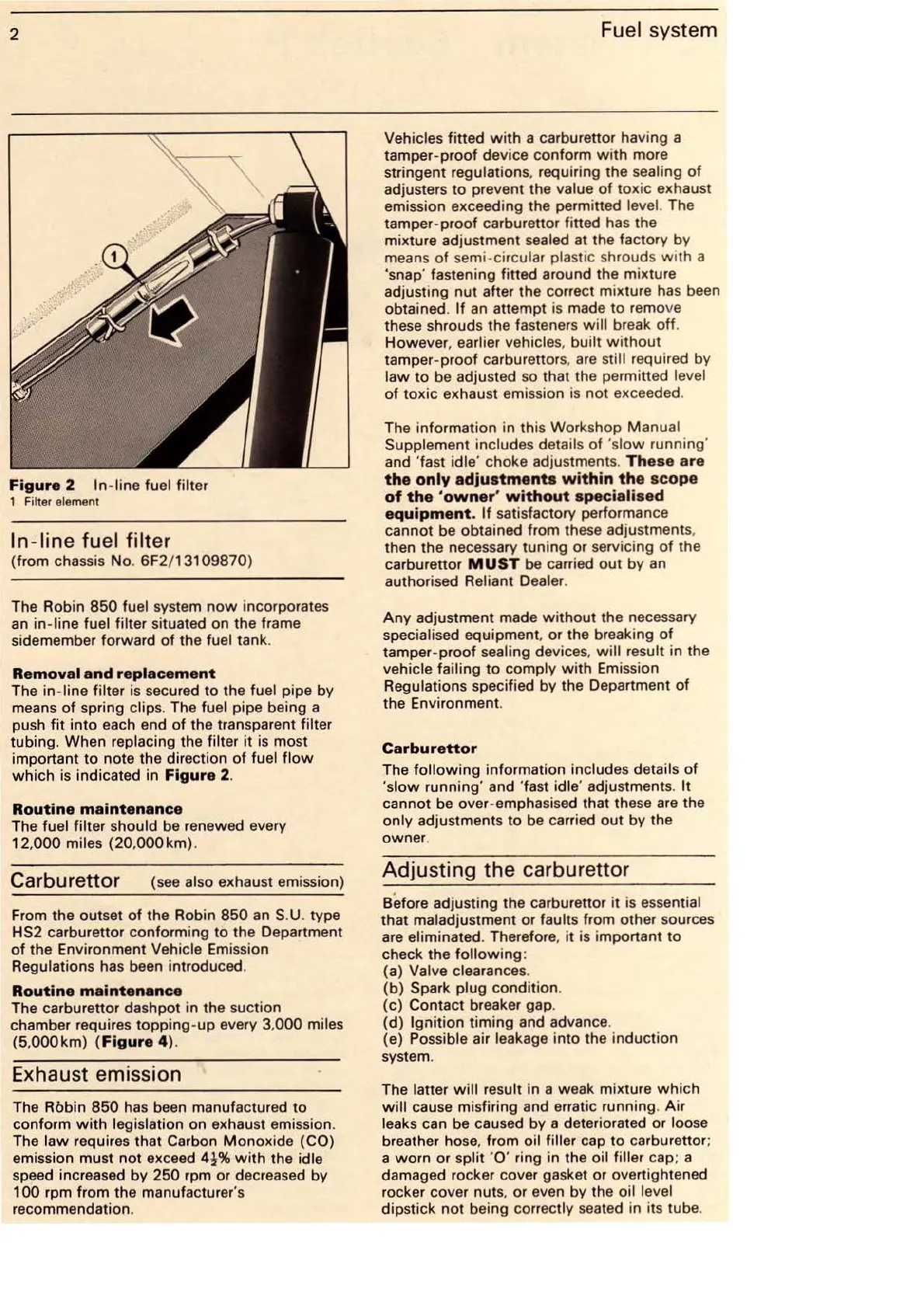

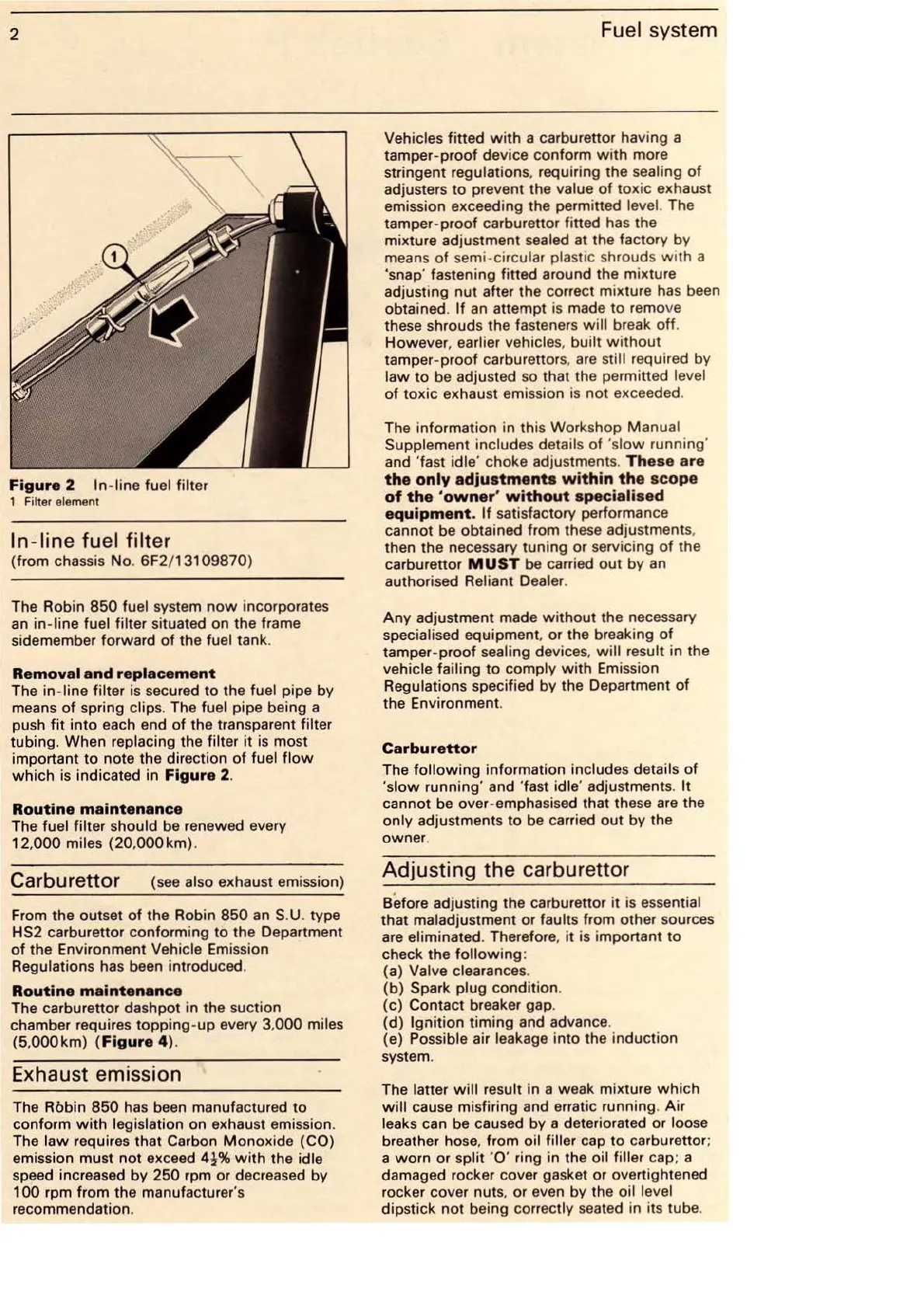

Figure

2

In-line

fuel filter

1 Filter element

In

-l

ine fuel fil

ter

(from chassis

No

. 6F2/

131

09870)

The Robin

850

fuel system

now

incorporates

an

in-line

fuel filter situated on the frame

sidemember forward

of

the fuel tank.

Remov

al a

nd

re

pl

a

cement

The in-line filter is secured

to

the fuel pipe

by

means

of

spring clips. The fuel pipe being a

push

fit

into each end

of

the transparent filter

tubing. When replacing the filter it

is

most

important

to

note the direction

of

fuel

flow

whic

h

is

indicated in Fi

gure

2.

Routine

maintenance

T

he

fuel filter should be renewed every

12,

000

miles (20,000km).

Ca

rbure

tt

or

(see also exhaust emission)

From the outset

of

the Robin 850

an

S.U. type

HS2 carburettor conforming

to

the Department

of

the Environment Vehicle Emission

Regulations has been introduced.

Routine

maintenance

T

he

carburettor dashpot in the suction

chamber requir

es

topping-up every 3,

000

miles

(5,000km)

(

Figure

4).

Exhaust emission

The Rbbin

850

has been manufactured

to

conform

with

legislation on exhaust emission.

T

he

l

aw

requir

es

that

Ca

rbon Monoxide (CO)

emission must

not

exceed 4

!%

with

the idle

speed increased

by

250 rpm or decreased by

100 rpm from the manufacturer's

recommendation.

Fu

el system

Vehicles fitted w i

th

a carburettor having a

tamper-proof device conform

with

more

stringent

regulations, requiring the sealing

of

adjusters

to

prevent the value

of

toxic exhaust

emission exceeding the permitted

level. The

tamper-proof carburettor fitted has the

m

ixt

ure adjustment sealed at the factory by

means

of

semi -circular plast

ic

sh

rouds wtth a

'snap' fastening fitted around the mixture

adjusting nut after the co

rre

ct

mixture

ha

s been

obtained.

If

an

attempt

is

made

to

remove

these shrouds the fasteners

will break

off

.

However,

earlier vehicles,

built

without

tamper-

proof

carburettors,

are

still required by

law

to

be adjusted

so

that the permitted level

of

toxic

exhaust emission

is

not

exceeded.

The information in this Workshop

Manual

Supplement includes details

of

'slow running'

and 'fast

idle' choke adjustments.

These

are

th

e

only

a

dju

s

tm

e

nt

s

wi

th

in the

scope

of

the

'owne

r'

w i

thou

t

specialised

equipment

.

If

satisfactory performance

cannot be obtained from these adjustments,

then the necessary tuning or servicing

of

the

carburettor

MUST

be

ca

rried

out

by

an

authorised

Reliant Dealer.

Any adjustment made

without

the necessary

specialised equipment, or the breaking

of

tamper-pr

oof

sealing devices,

will

result in the

vehicle failing

to

comply

with

Emission

Regulations specified

by

the Department

of

the Environment.

Carbu

r

etto

r

T

he

foll

owing

information includes details

of

'slow

running' and 'fast idle' adjustments. It

cannot be over-emphasised that these are the

only adjustments

to

be carried

out

by the

owner.

Adju

sting the carburettor

Before adjusting the carburettor

it

is essential

that maladjustment or faults from other sources

are

eliminated. Therefore,

it

is

important

to

check the

following

:

(a) Valve clearances.

(b) Spark

plug condition.

(c)

Contact breaker gap.

(d)

Ignition timing and advance.

(e)

Possible air leakage into the induction

system.

The

latter

will

resu

lt in a weak mixture

which

wi

ll cause misfiring and erratic running.

Air

leaks can

be

caused

by

a deteriorated or loose

breather hose, from oil filler cap

to

carburettor;

a worn or

spl

it

·o·

ring in the oil filler cap; a

damaged rocker cover gasket or overtightened

rocker cover nuts,

or

even by the oil level

dipstick not being correctly seated in its tube.

Loading...

Loading...