El

ectrics Sec

ti

on T

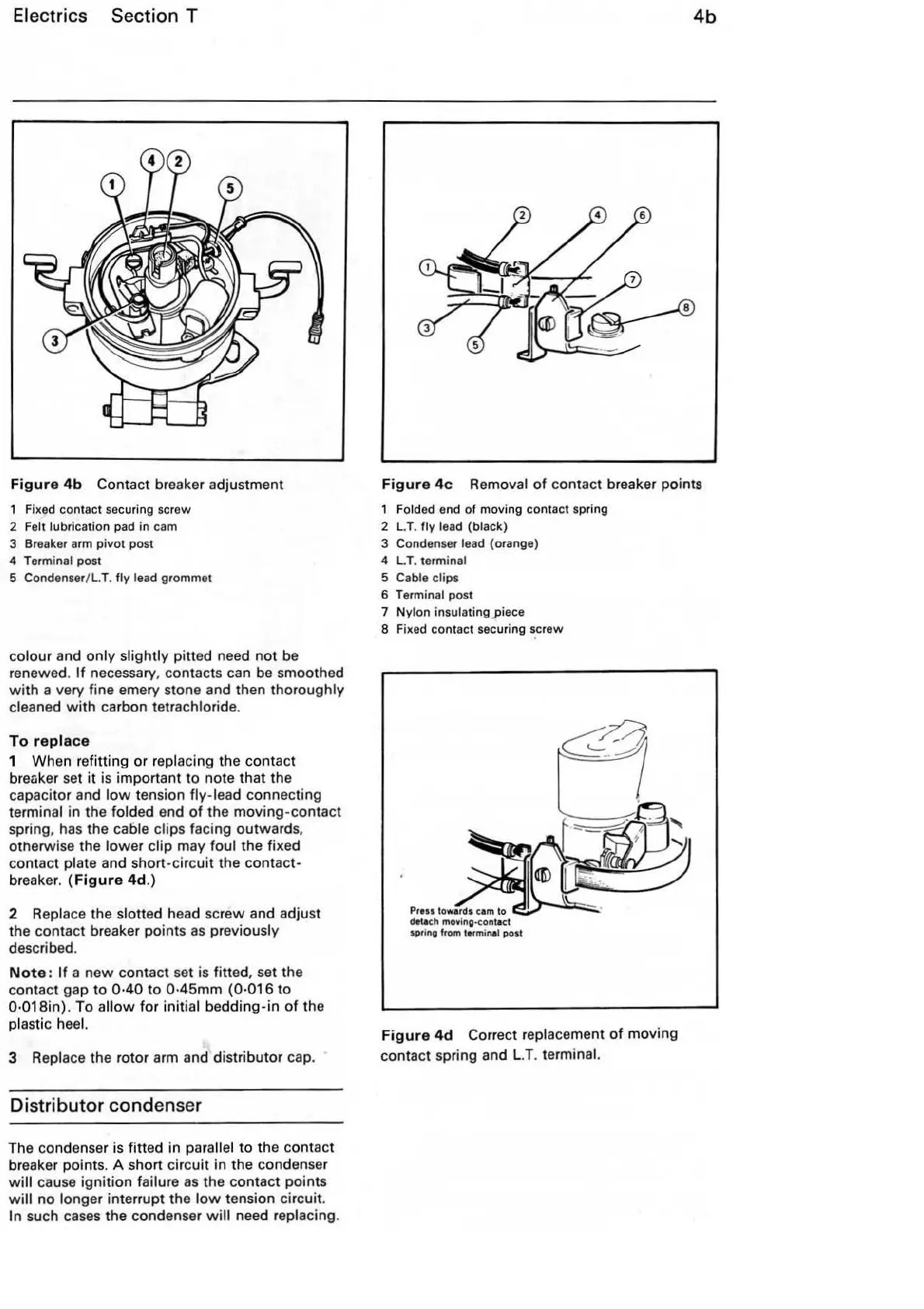

Fi

gu

re

4b

Contact breaker adjustment

Fixed contact securing screw

2

F

el

t lubrication pad in

cam

3 Breaker arm pivot post

4

Terminal post

5 Condenser/ L.T.

fly lead grommet

colour and

only

slightly pi

tt

ed need

not

be

renewed.

If

necessary, contacts can

be

smoothed

with

a very fine emery stone and then thoroughly

cleaned

with

carbon tetrachloride.

To

rep

l

ace

1 When refitting or replacing the contact

breaker set

it

is important to note that the

capacitor and

low

tension

fly

-lead connecting

terminal in the folded end

of

the moving-contact

spring,

has

the cable clips facing outwards,

otherwise the lower

clip may foul the fixed

contact

plate and short-circuit the contact-

breaker. (

Figur

e 4d.)

2 Replace the slotted head screw and adjust

the contact breaker points

as

previously

described.

Not

e:

If

a

new

contact set is fitted, set the

contact gap

to

0·40

to 0·

45mm

(0·016

to

0·018in). To a

ll

ow

fo

r initi

al

bedd

ing-in

of

the

plastic

heel.

3

Rep

lace the rotor arm and distributor cap.

Distribut

or

conden

se

r

The condenser is fi

tt

ed

in parallel to the contact

breaker points. A short circuit in the condenser

wi

ll cause ignition failure

as

the contact points

will

no

longer interr

upt

the l

ow

tension circuit.

In such cases the condenser

will

need replacing.

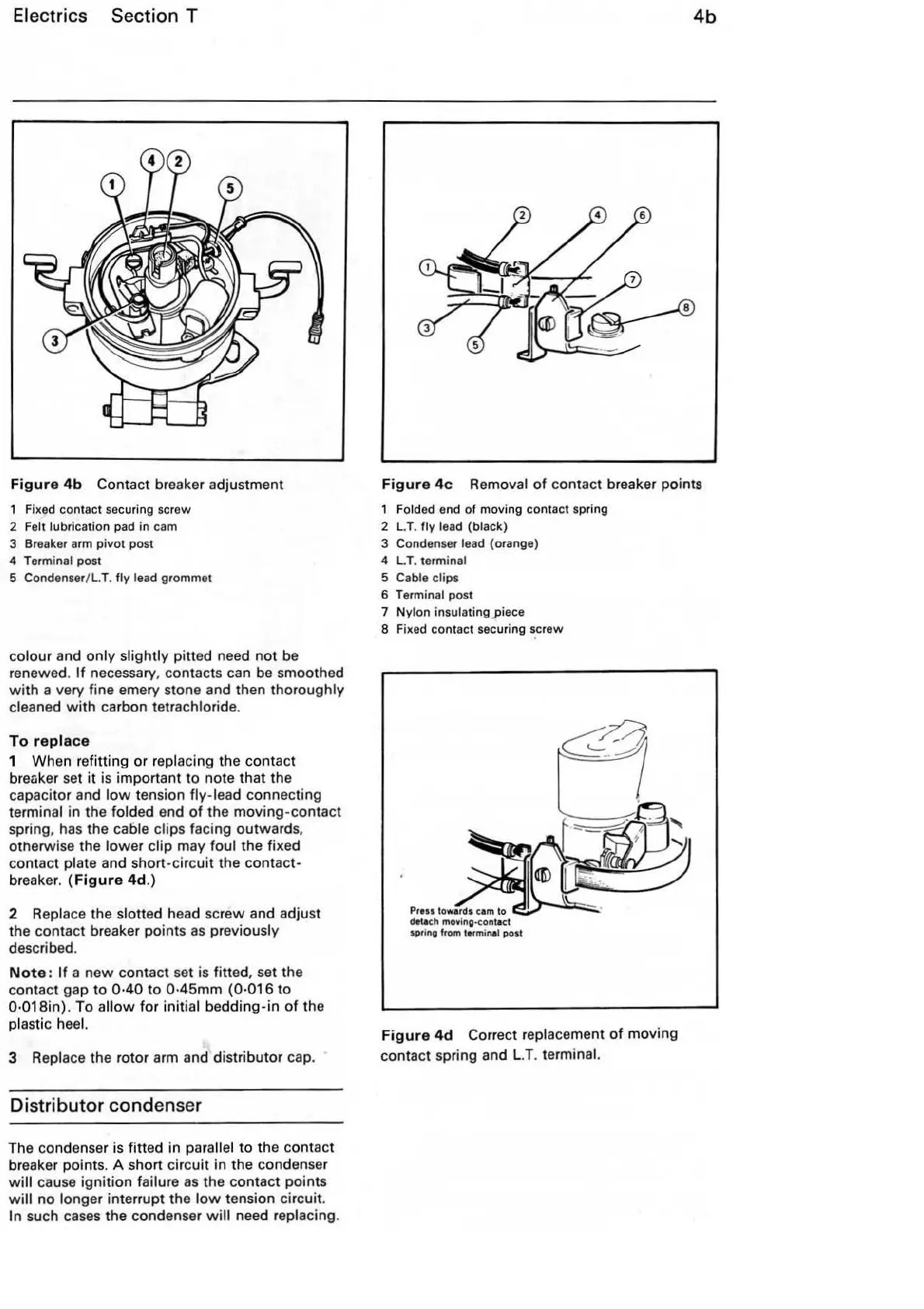

4b

F

igure

4c Removal

of

contact breaker points

1 Folded end of moving contact spring

2

LT.

fly

lead {black)

3 Condenser lead {orange)

4

LT.

terminal

5 Cable clips

6

Term

inal post

7

Nylon insulating piece

8 Fixed contact securing screw

Figur

e

4d

Correct replacement

of

moving

contact spring and L.T.

terminal.

Loading...

Loading...