El

ect

ri

cs Section T

Fig

ur

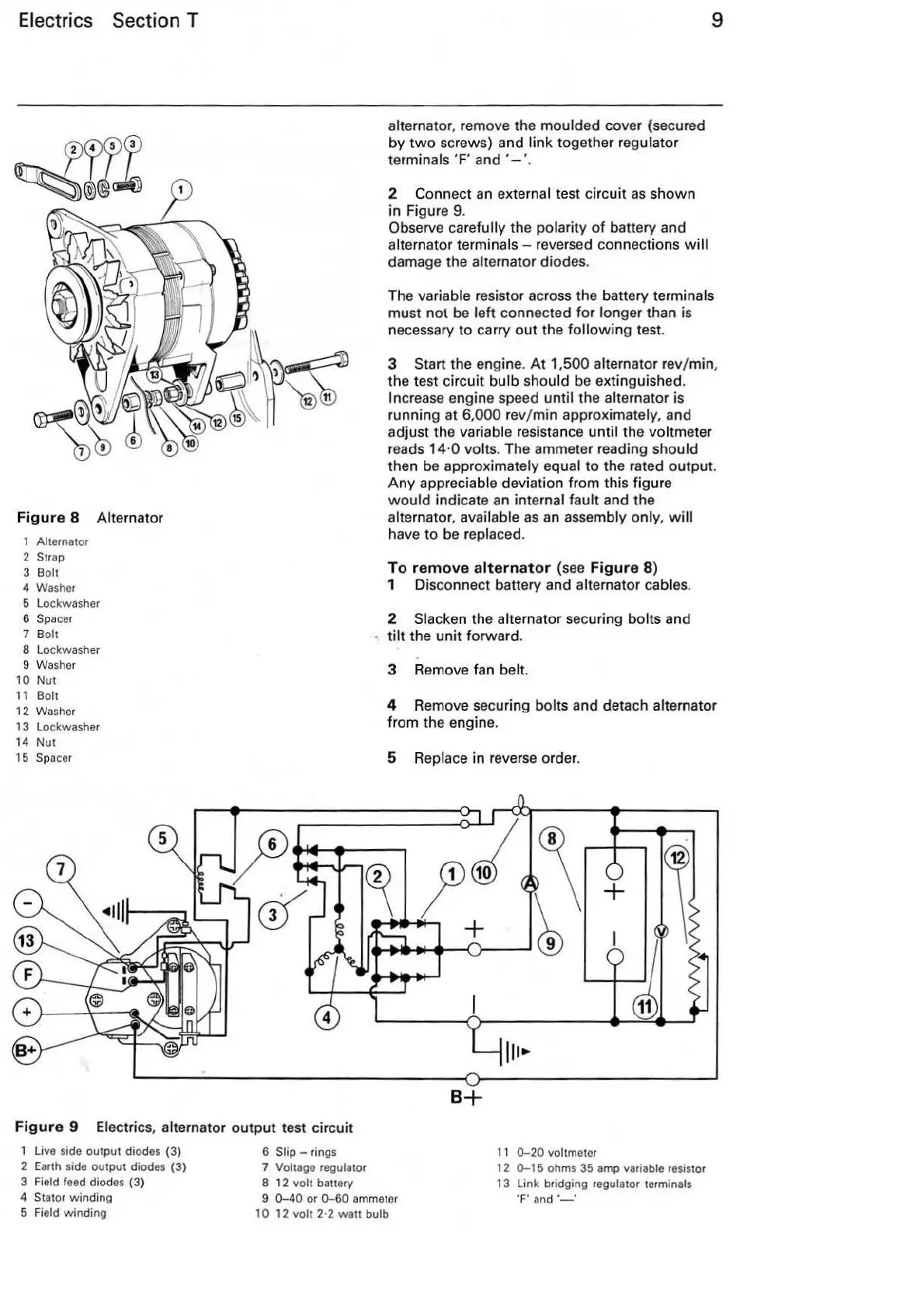

e 8 Alternator

1 Alternator

2

Strap

3 Bolt

4 Washer

5 Lockwasher

6

Sp

acer

7 Bolt

8 Lockwasher

9 Washer

10

Nut

11 B

olt

12

Washer

13 Lockwasher

14

Nut

15

Sp

acer

alternator, remove the moulded cover (secured

by

two

screws) and

link

together regulator

terminals

'F' and

'-

'.

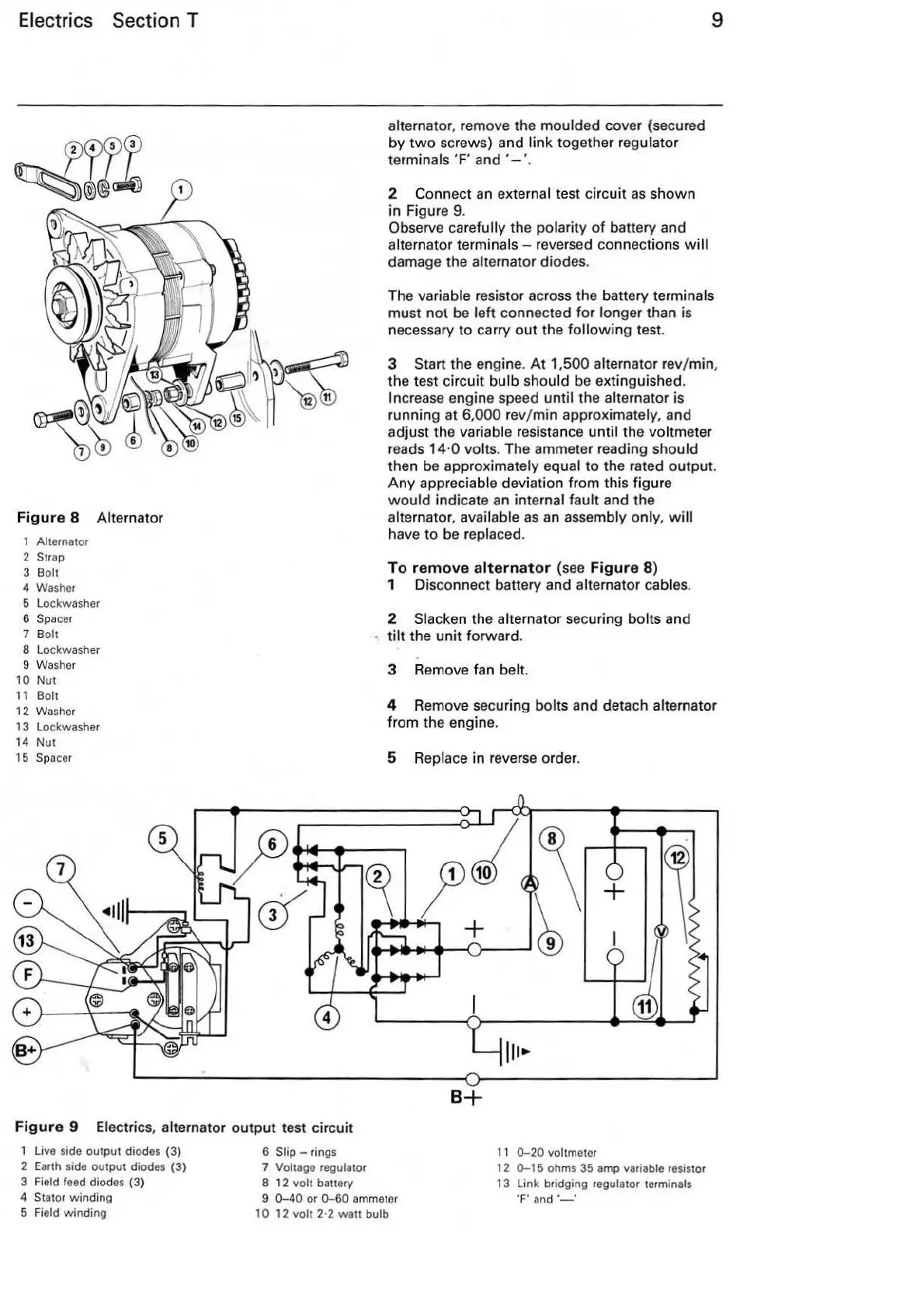

2 Connect

an

external test circuit

as

shown

in

Figure 9.

Observe

carefully the polarity

of

ba

ttery and

alternator

terminals - reversed connections w ill

damage the alternator diodes.

9

The variable resistor across the battery terminals

must not be left connected for longer than is

necessary to carry

out

the

following

test.

3

Start the engine.

At

1,500 alternator

re

v/

min,

the test circuit

bulb should be extinguished.

Incre

ase

engine speed until the alternator is

ru

nning at 6,000 rev/ min approximately, and

adjust the

variable resistance until the voltmeter

reads

14

·0 volts. The ammeter reading should

then be approximately equal to the rated output.

Any

appreciable deviation from this figure

would

indi

cate an

int

ernal fault and the

alternator, available

as

an assembly onl

y,

will

have

to

be replaced.

To r

emove

a

lt

ernator

(see F

igure

8)

1 Disconne

ct

battery and alternator cables.

2

Slacken the alternator

se

curing bolts and

tilt

the

unit

forward.

3 Remove fan belt.

4 Remove securing bolts and detach alternator

from the engine.

5 Replace in reverse order.

+

B+

Fi

gur

e 9 Electrics, alternator

output

test circuit

1 Live side output diod

es

(3)

2 Earth side output diodes

(3)

3 Field f

ee

d diodes

(3)

4 Stator winding

5

Field winding

6 Slip - rings

7 Voltage regulator

8

12

volt banery

9

0-40

or

0-60

ammeter

10

12

volt 2·2

watt

bulb

11

0-20

voltmeter

12

0-15

ohms 35 amp variable

res

is

tor

13

Link bridging regulator terminals

T

and·-·

Loading...

Loading...