The engine Section F

Figure

24

Removing cylinder liners

block

using a tool similar to that shown in

Figure

24

.

3 Remove all signs

of

sealing compound from

both the

liners and their seats

in

the cylinder

block.

4 Machine the liners 0·254mm {0·01 Oin).

Note

: Pistons 0·254mm (0·010in) oversize

must

be

fitted.

Alternatively the four liners should be replaced·

and standard pistons fitted.

5

Smear I

CI

'Silcoset

152

' sealing compound

around the seating face

of

the liner and its

location

in

the cylinder

block

~

making a

complete 360°

sea

l (see

Figure

25

).

Cylinder

Liner

·

Silcosef

Sealant

Figure

25

Sea

ling

cy

lind

er

liners

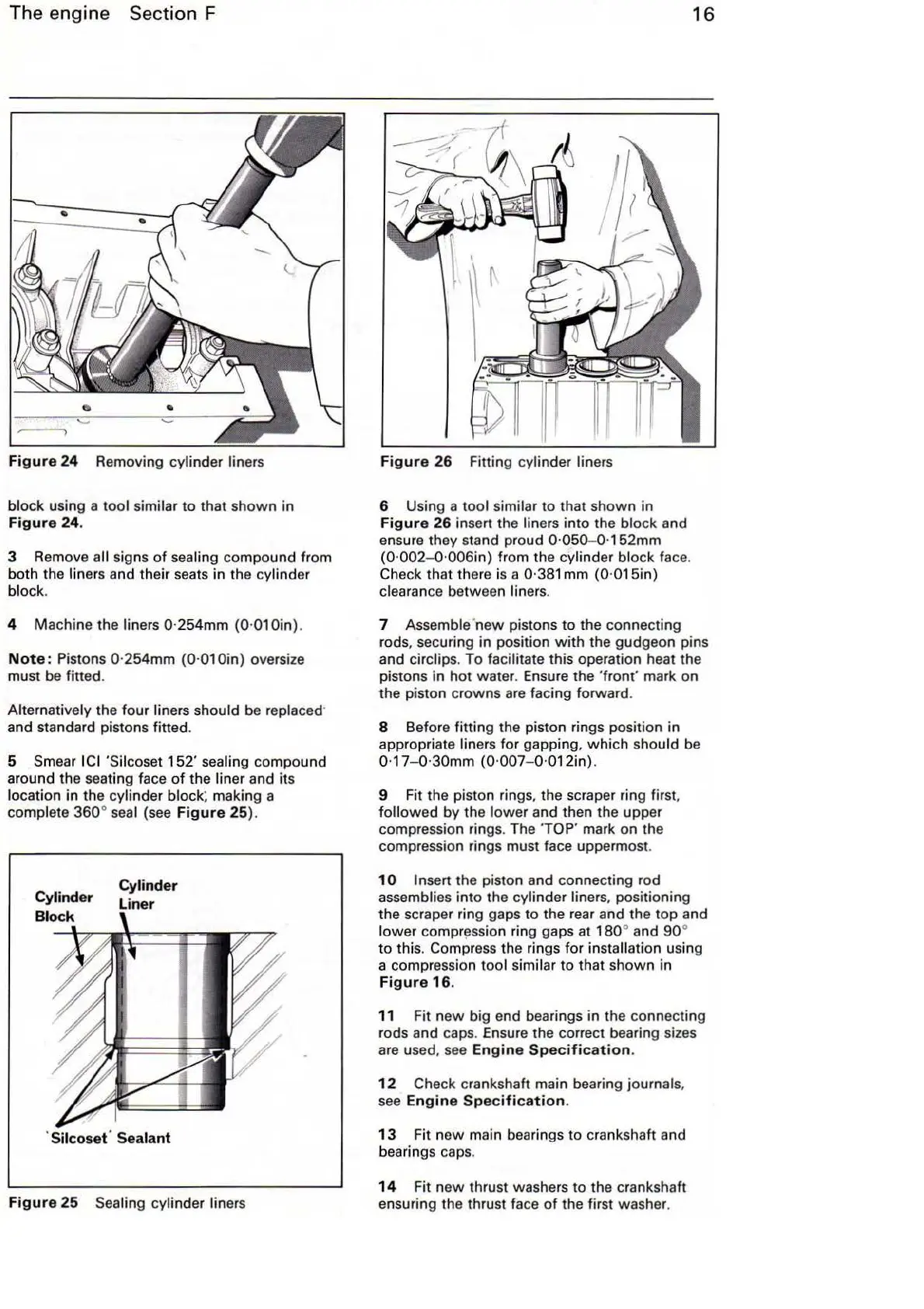

Figure

26

Fitting cylinder liners

6 Using a tool similar to that shown in

Figure

26 insen the liners into the block and

ensure they stand proud

0·050-0·152mm

{0·002- 0·006in) from the cylinder block face.

Check that there is a 0·381

mm

{0·015in)

clearance

between liners.

16

7 Assemble'

new

pistons to the connecting

rods, securing in position

with

the gudgeon pins

and

circlips. To facilitate this operation heat the

pistons

in

hot

water. Ensure the

'fro

nt'

mark on

the piston crowns are facing forward.

8 Before fitting the piston rings position in

appropriate

liners for gapping,

which

should be

0·17-0

·30mm

(0·007-0

·012in).

9 Fit the piston rings, the scraper ring first,

followed

by the

lower

and then the upper

compression rings. The

TOP'

mark on the

compression rings must face uppermost.

1

0 I nsen the piston and connecting rod

assemblies

into

the cylinder liners, positioning

the scraper ring gaps

to

the rear and the top and

lower

compr~ssion

ring gaps at

180

° and

90

°

to this. Compress the rings for installation using

a compression

tool similar to that shown in

Figure

16

.

11

Fit

new

big end bearings in the connecting

rods and caps. Ensure the correct bearing sizes

are used, see

Engine

Specification

.

12

Check crankshaft main bearing journals,

see

Engine

Specification.

13

Fit new main bearings to crankshaft and

bearings caps.

14

Fit

new

thrust washers

to

the crankshaft

ensuring the thrust

fa

ce

of

the first washer.

Loading...

Loading...