4

24

Re

connect water pump and thermostat

housing hoses

to

manifold adaptor.

26

Reconnect choke cable and accelerator

cable

at carburett

or

.

26

R

efit

air cleaner.

27

Reconnect high and

low

tension leads

at coil.

28

Reconnect oil pressure warning light l

ead

.

or

oil pressure pipe

if

gauge is fitted.

29

Reconnect temperature gauge sender unit

lead at thermostat housing.

30

Reconnect starter motor lead.

31

Refit alternator and connect leads.

32

Reconnect heater hose at cylinder head

adaptor. refit

jubilee clip and secure hose

to

mounting bracket attached

to

rocker cover

stud.

33 Reconnect heater hose at water pump

and secure

with

jubil

ee

clip.

34

Reconnect radiator bottom hose at

water pump.

35

Reconnect radiator top hose at thermostat

housing.

36

Refill engine and gearbox

with

recommended oil.

37 Refill the cooling system.

38

R

econnectbatte~

.

Operation 2 - Flywheel and ring

gear

removal and replacement

Flywheel

removal

1 Remove the gearbox (see

Section

G).

2 Unscrew six set screws.

complete

with

lockwashers. and remove the clutch assembly

from the flywheel.

3 Release the tabwasher. unscrew three set

screws, and remove the

flywheel assembly

from the crankshaft.

Starter

ring

gear

removal

1 Drill a hole

6·35mm

(0

·

25i

n) diameter at

the point

of

intersection

of

a scribed line

between any

two

teeth and a scribed line

midway between the r

oot

diameter and the

inside diameter

of

th

e ring gear.

En

sure that

the

hole is

not

drilled through the ring gear

into the

flywheel.

as

this

will

interfere

with

the

subsequent

balance

of

the flywheel.

The engine

2 Hold

th

e flywheel assembly in a soft-jawed

vice.

3

Place a

clot

h

of

heavy material over the

ring gear

as

a protection against flying

fragments.

Warning

:

En

sure adequate protection,

particularly for the eyes,

to

prevent injury from

the

possibility

of

flying fragments when the

ring gear is

split.

4 Place a cold chisel immediately above the

centre

line

of

the drilled hole and strike

sharply

to

split the ring gear.

Refitting

1 Heat the replacement ring gear uniformly

to

a maximum

of

200"C.

2 Place the flywheel on a flat surface. clutch

face side uppermost. and clean the ring gear

locating surface.

3 Locate the ring gear and

hold in position

until

it

contracts sufficiently

to

grip the

flywheel.

4

Allow

the ring gear

to

cool gradually

to

avoid distortion.

'

C>

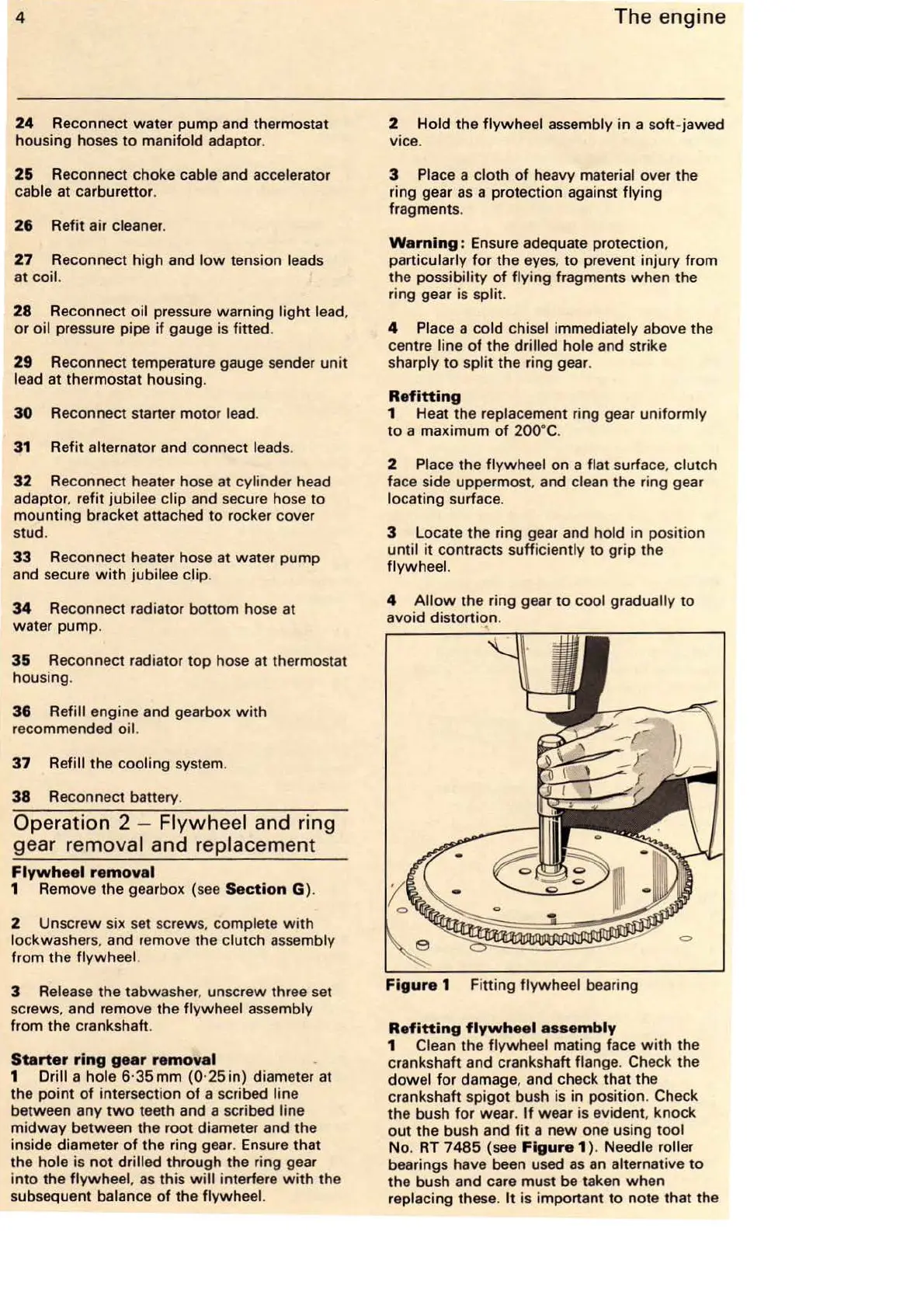

Figure

1 Fitting flywheel bearing

Refitting

flywheel

assembly

1 Clean the flywheel mating face

with

the

crankshaft and crankshaft

flange. Check the

dowel for damage, and check that the

crankshaft spigot bush is in position.

Check

the bush for wear.

If

wear is evident, knock

out

the bush and

fit

a

new

one using tool

No.

RT

7485

(see

Figure

1)

. Needle roll

er

bearings have been used

as

an

alternative

to

the bush and care must be taken when

replacing these.

It

is important

to

note that the

Loading...

Loading...