Robin

850

Workshop

Manual

Supplement

The engine

hardened, square end face

of

the bearing must

face the

tool

used

to

press in the bearing. Use

of

the rolled end

of

the bearing

will

lead to

shell distortion and needle failure. The

manufacturer's name and designation number

may be stamped on the hardened end face in

so

me

instances, enabling

it

to be easily

identified. However, this does

not

apply

with

all manufacturers and care should be

exercised

to

identify the correct end by its

shape.

2 Fit the flywheel

to

the crankshaft, locating

over the dowel in the crankshaft.

3 Secure the flywheel assembly to the

crankshaft

with

three set screws. and a

tabwasher, tightening

to

a torque

of

4·

03

kg m

(291bft). The tabs

of

the

washer should then

be bent over to lock the set screws.

4 Check the flywheel for misalignment using

a clock indicator gauge. A

0·

08-0

·

13

mm

(0

·

003

-

0·005

in) run-out is permitted, but

if

this is exceeded the flywheel must be

replaced

with

a

new

assembly.

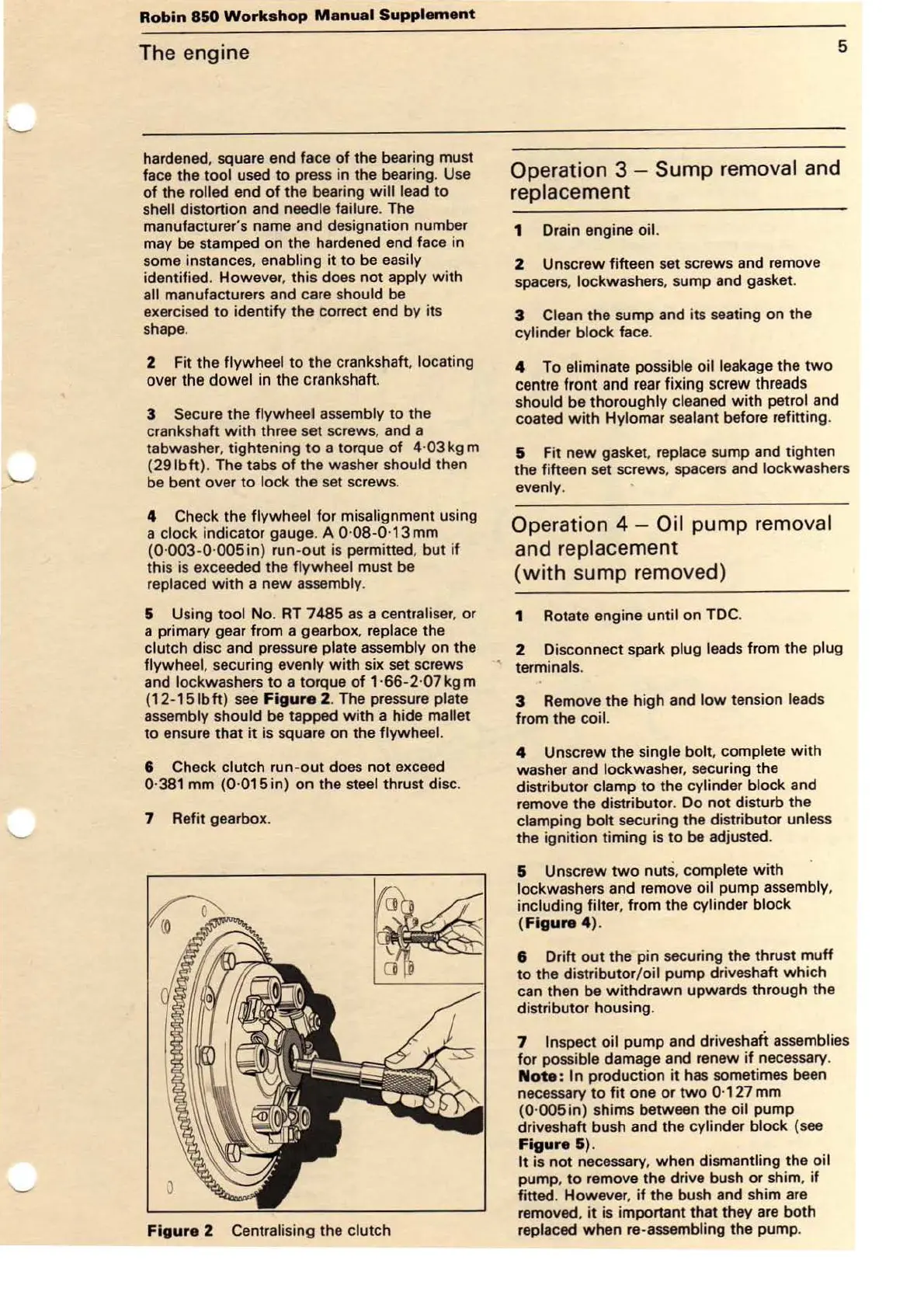

5 Using tool

No

.

RT

7485

as

a centraliser, or

a primary gear from a gearbox, replace the

clutch disc and pressure plate assembly on the

flywheel, securing evenly

with

six set screws

and lock washers to a torque

of

1·66-2

·

07

kg m

(12-151bft)

see

Figure

2.

Th

e pressure plate

assembly should be tapped

with

a hide mallet

to

ensure that

it

is square on the flywheel.

6 Check clutch run

-o

ut

does

not

exceed

0·381 mm

(0

·

015

in)

on

the steel thrust disc.

7 Refit gearbox.

Figure

2 Centralising the clutch

5

Operation 3 -

Sump

removal and

replacement

1 Drain engine oil.

2 Unscrew fifteen set screws and remove

spacers, lockwashers, sump and gasket.

3 Clean the sump and its seating on the

cylinder block face.

4

To

eliminate possible oil leakage the

two

centre front and

rear

fixing screw threads

should be thoroughly cleaned

with

petrol and

coated

with

Hylomar sealant before refitting.

5 Fit

new

gasket, replace sump and tighten

the fifteen set

sc

rew

s, spacers and lockwashers

evenly.

Operation 4 - Oil

pump

removal

and replacement

(with

sump removed)

1 Rotate engine until on TDC.

2 Disconnect spark plug leads from the plug

terminals.

3 Remove the high and

low

tension leads

from the

coil.

4 Unscrew the single

bolt

, complete

with

washer and lockwasher, securing the

distributor clamp to the cylinder block and

remove the distributor. Do not disturb the

clamping

bolt

securing the distributor unless

the

ignition timing is

to

be adjusted.

5 Unscrew

two

nuts, complete

with

lockwashe

rs

and remove oil pump assembly,

including

filter, from the cylinder block

(Figure

4).

6 Drift out the pin securing the thrust muff

to the distributor/oil pump driveshaft

which

can then be

withdrawn

upwards through the

distributor housing.

7 Inspect oil pump and driveshatt assemblies

for possible damage and renew

if

necessary.

Note:

In production

it

ha

s sometimes been

necessary

to

fit

one

or

two

0·127 mm

(0

·

005

in) shims between the oil pump

driveshaft bush and the cylinder block (see

Figure&)

.

It

is not necessary, when dismantling the oil

pump,

to

remove

the

drive bush

or

shim,

if

fitted. However,

if

the bush and shim are

removed,

it

is important that they are both

replaced when re-assembling the pump.

Loading...

Loading...