Robin

850

Workshop

Manual

Supplement

The engine

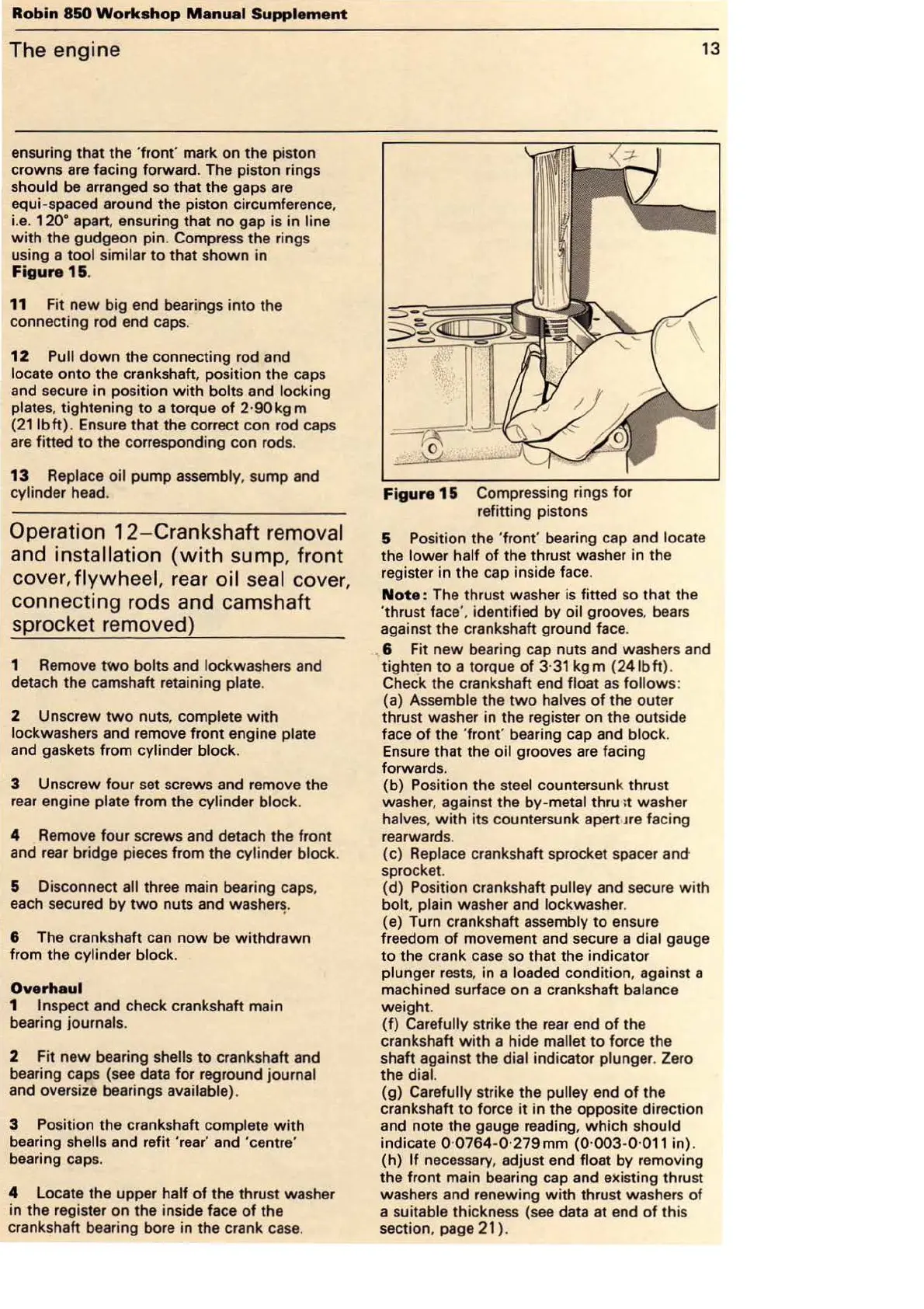

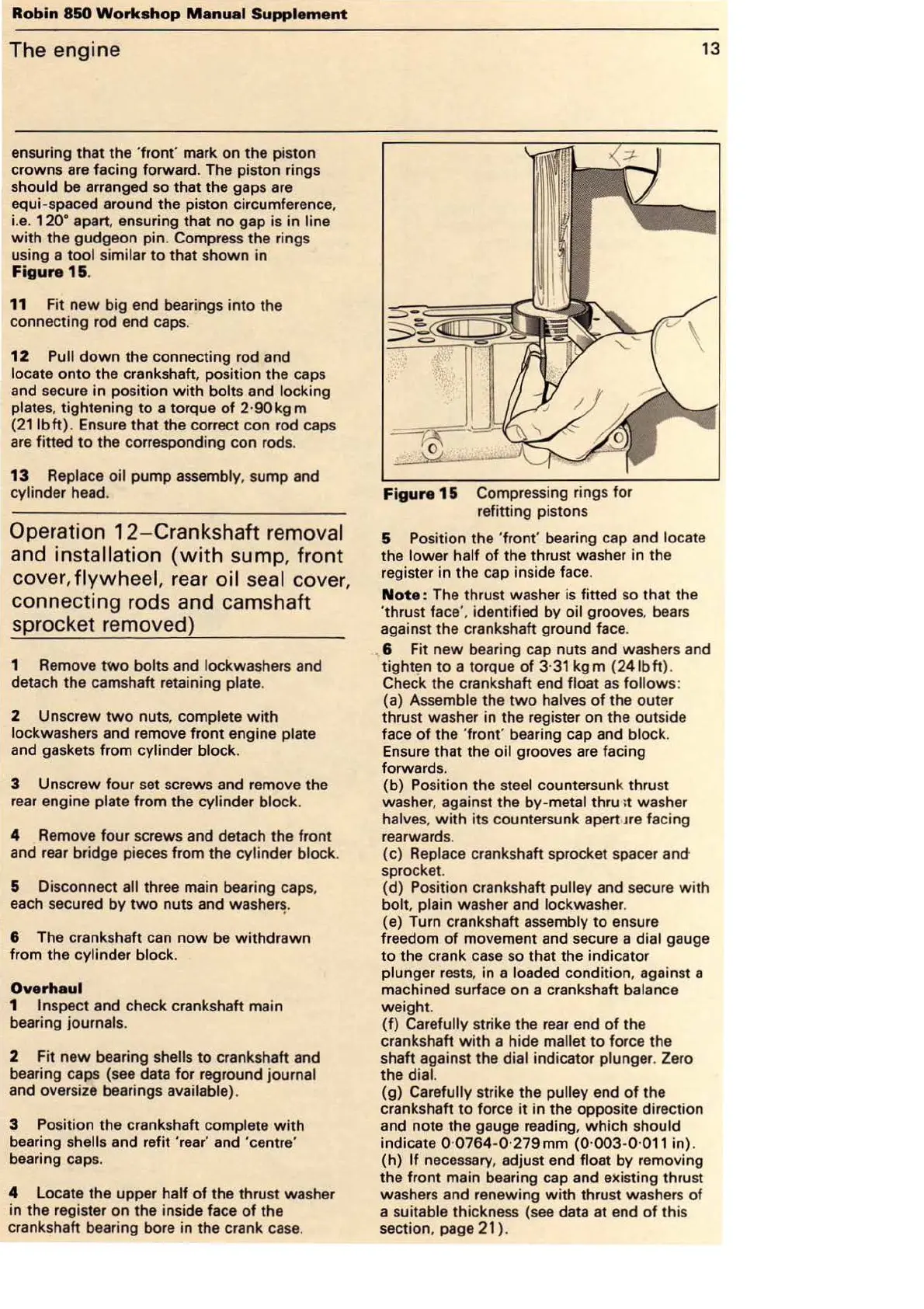

ensuring that the

'f

ront' mark on the piston

crowns are facing forward. The piston rings

should be arranged so that the gaps are

equi-spaced around the piston circumference.

i.e.

120

• apart. ensuring that no gap is in line

with

the gudgeon pin. Compress the rings

using a

tool similar to that shown in

Figure

1&.

11 Fit new big end bearings into the

connecting rod end caps.

12

Pull

down

the connecting rod and

locate onto the crankshaft. position the caps

and secure in position

with

bolts and locking

plates,

tightening

to

a torque

of

2

·90kg

m

(211bft). Ensure that the correct con rod caps

are fitted

to

the corresponding con rod

s.

13

Replace oil pump assembly, sump and

cylinder head.

Operation

12

- Crankshaft removal

and installation

(with

sump

, front

cover,

flywheel, rear

oil

seal cover,

connecting rods and camshaft

sprocket removed)

1 Remove

two

bolts and lockwashers and

detach the camshaft retaining

plate.

2 Unscrew

two

nuts, complete

with

lockwashers and remove front engine plate

and gaskets from cylinder block.

3 Unscrew

four

set screws and remove the

rear engine

plate from the cylinder block.

4 Remove four screws and detach the front

and rear bridge pieces from the

cylinder block.

& Disconnect all three main bearing caps,

each secured by

two

nuts and

washer~

.

6 The crankshaft can

now

be

withdrawn

from the cylinder block.

Overhaul

1 Inspect and check crankshaft main

bearing

journals.

2 Fit new bearing shells

to

crankshaft and

bearing caps (see data for reground

journal

and oversize bearings available).

3 Position the crankshaft complete

with

bearing shells and refit 'rear' and 'centre'

bearing caps.

4 Locate the upper half

of

the thrust washer

in the register on the inside face

of

the

crankshaft bearing bore in the crank case.

13

Figure 1 & Compressing rings for

refitting pistons

5 Position the

'f

ront' bearing cap and locate

the lower half

of

the thrust washer in the

register in the cap inside face.

Note

: The thrust washer

is

fitted

so

that the

'thrust

face

',

identified by oil grooves,

bears

against the crankshaft ground face .

. 6 F

it

new bearing cap nuts and washers and

tighten

to

a torque

of

3·

31

kgm

(241bft).

Check the crankshaft end float

as

follows:

(a) Assemble the

two

halves

of

the outer

thrust washer in the register on the outside

face

of

the

'f

ront' bearing cap and block.

Ensure that the oil grooves

are

facing

forwards.

(b) Position the

steel countersunk thrust

washer, against the

by-metal thru >t washer

halve

s,

with

its countersunk apert

Jre

facing

rearwards.

(c)

Replace crankshaft sprocket spacer

and

sprocket.

(d)

Po

sition crankshaft pulley and secure

with

bolt, plain washer and lockwasher.

(e) Turn crankshaft assembly to ensure

freedom

of

movement and secure a dial gauge

to the crank

case

so that the indicator

plunger rest

s.

in a loaded condition, against a

machined surface on a crankshaft

balance

weight.

(f)

Carefully strike the

rear

end

of

the

crankshaft

with

a hide mallet to force the

shaft against the

dial indicator plunger. Zero

the dial.

(g) Carefully strike the pulley end

of

the

crankshaft

to

force

it

in the oppo

si

te direction

and note the gauge reading,

which

should

indicate 0·

0764

-0·279mm

(0

·

003

-0·

011

in).

(h)

If

necessary, adjust end float by removing

the front main bearing cap and existing thrust

washers and renewing

with

thrust washers

of

a suitable thickness (see data at end

of

this

section, page

21

).

Loading...

Loading...