14

The en

gi

ne

Refit bearing cap complete w

it

h shell

bearings and recheck the end floa

t.

To

replace

Replace components in

re

v

erse

order.

Note:

The end float m

ay

also

be

checked

with

f

ee

l

er

gauges inserted be

tw

een

the thrust

washer and the ground face

of

the

Note

: When refitting front and

rea

r bridge

pieces

ca

re should be taken to

en

sure that

th

eir faces

ma

te flush

wit

h the cylinder block

fac

e.

N

ew

cork inserts should be fitted when

replacing bridge pieces. crankshaft.

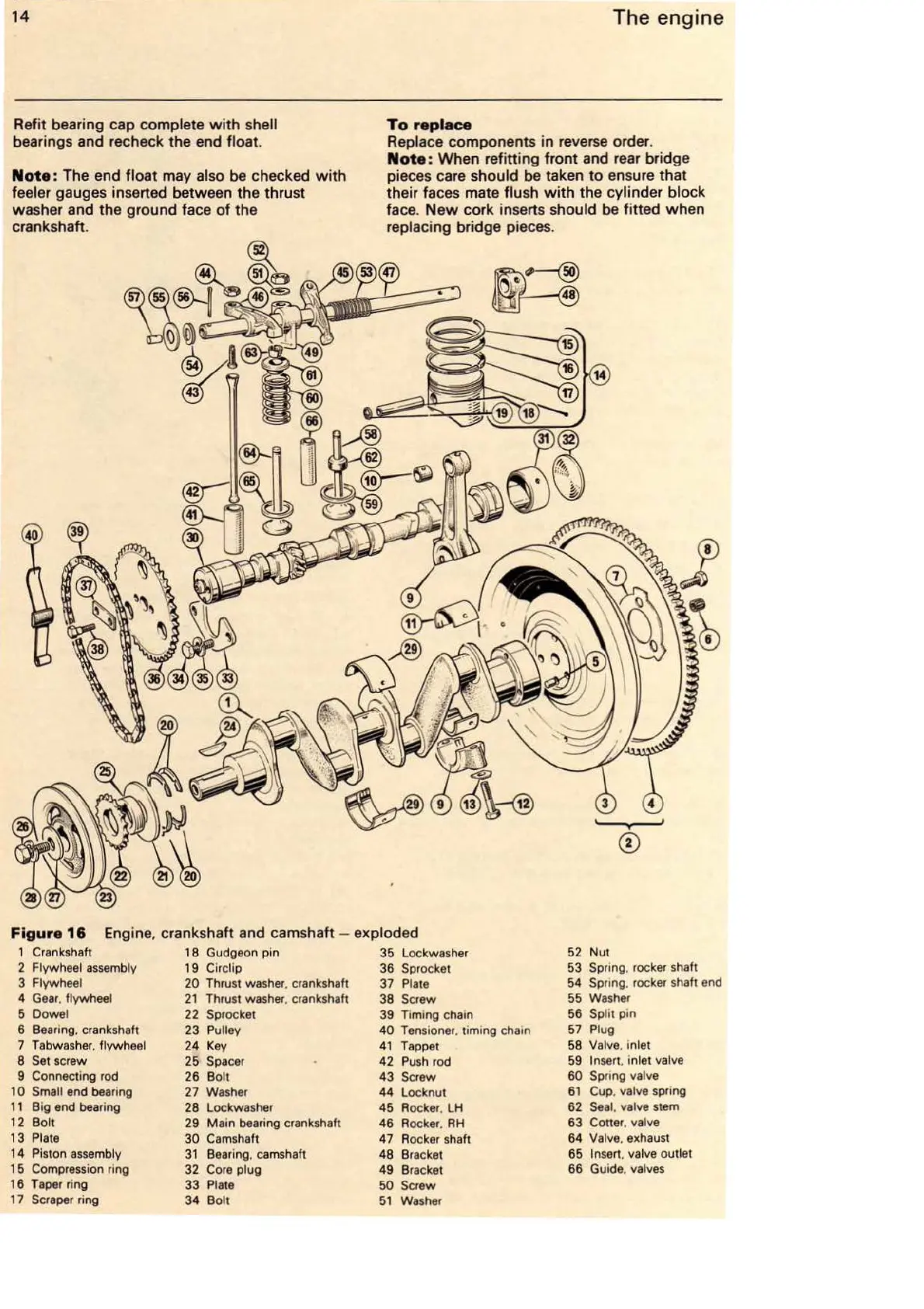

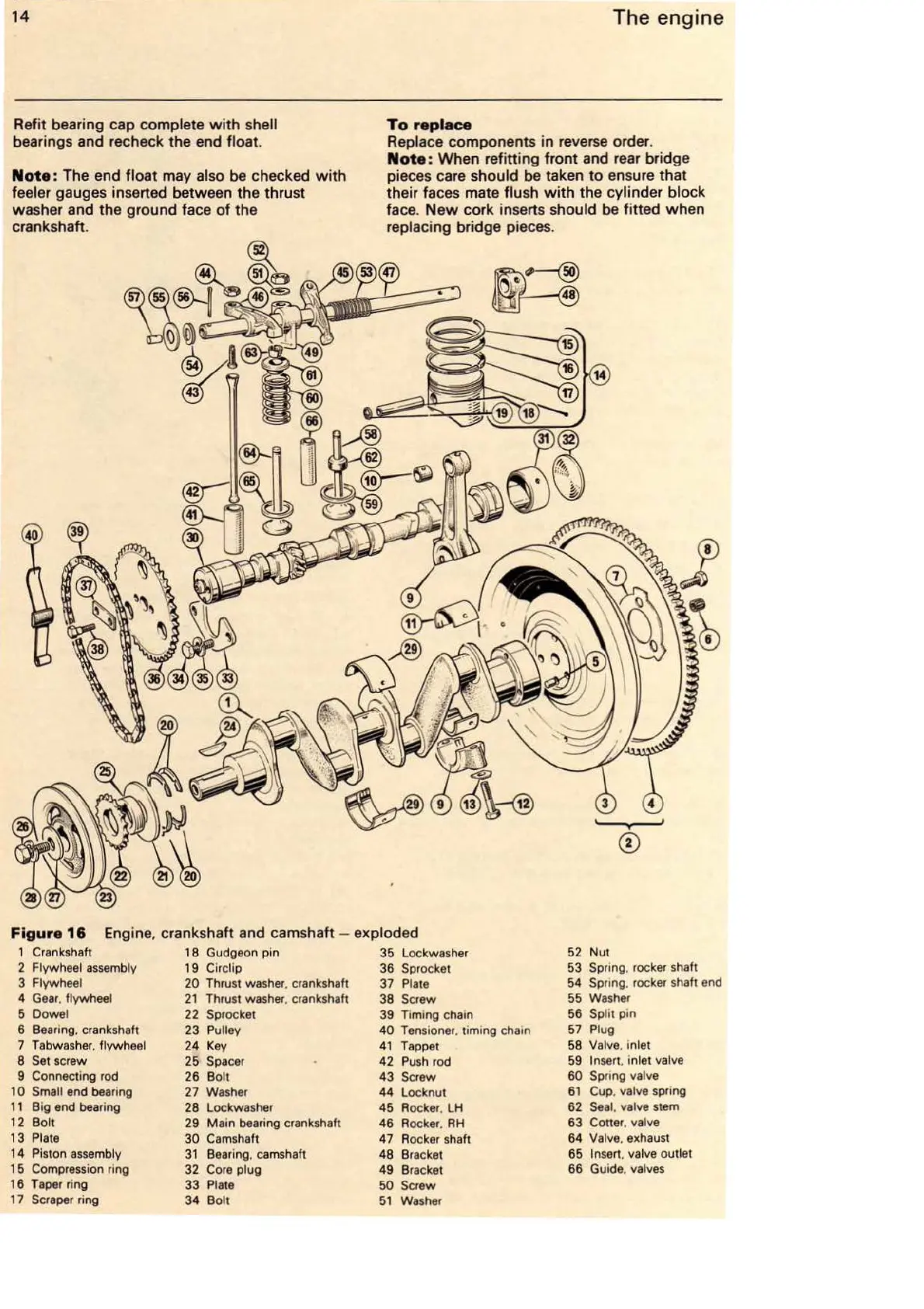

Figure

16

1 Crankshaft

Engin

e,

crankshaft and camshaft - exploded

2 Flywh

eel

assembly

3

Flywheel

4 Gear. flywheel

6 Dowel

6 Bearing. crankshaft

7 Tabwasher.

fl

ywh

ee

l

8

Se

t screw

9 Connecting rod

1 0 Small end bearing

11

Big end bearing

12 B

olt

13

Pl

ate

1 4 P

is

ton

ass

embly

16 Compression ring

16

Taper ring

1 7 Scraper ring

18 Gudgeon pin 35 Lockwasher

19 Circllp 36 Sprocket

20

Thrust washer. crankshaft 37 Plate

21 Thrust washer. crankshaft 38 Screw

22

Sprocket 39

T1m

ing chain

23

Pulley

40

Tens1oner

. timing

cha1n

24 K

ey

41 Tappet

25 Spacer 42

Push

rod

26

Bolt 43 Screw

27 Washer 44 Locknut

28 Lockwasher 46 Rocker. LH

29 M ain bearing crankshaft 46 Rocker.

RH

30

Camshaft 47 Rocker shaft

31 Bearing. camshaft 48 Bracket

32 Core

plug 49 Bracket

33 Plate

50

Screw

34 Bolt

51

Washer

52 Nut

53

Spring. rocker shaft

54 Spnng. rocker shaft end

55 Washer

56

Spht pin

57

Plug

68 Valve. inlet

59 Insert. inlet valve

60

Spring valve

61 Cup. valve spring

62

Sea

l. valve stem

63

Coner. valve

64 Valve. exhaust

65

Insert. valve outlet

66

Guide. valves

Loading...

Loading...