20

24

Replace crankshaft pulley and secure

with

bolt

, plain washer and lockwasher.

21

Locate a

new

gasket and then

fit

the oil

pump assembly, complete

with

filter, securing

to

the cylinder block

with

two

nuts and

lockwashers. Refit

oil pump and distributor

drive shaft.

21

Fit a

new

gasket and replace the sump,

tightening the fifteen set screws, spacing

washers and lockwashers evenly.

27

Clean the cylinder head and cylinder

block faces and

fit

a new gasket. Smear grease

around the metal edges

of

the gasket bore

eyelets.

28

Carefully position the cylinder head

squarely on the cylinder block and secure

with

the twelve nuts, plain washers and

lockwashers. Replace the three nuts on the

spark

plug side

of

the cylinder head. Check

that

all cylinder head nuts indicated in

Figure13

are tightened, in the order shown,

to

a torque

of

3·46kgm

(251bft). The three

remaining nuts, on the spark

plug side, should

be tightened

to

a torque

of

2·

07

kg m

(151bft).

29 Replace the push rods ensuring they

are

replaced in their correct order.

30 Locate the rocker shaft assembly on the

four studs and secure firmly

with

the four nuts

and washers

to

a torque

of

2·35-3·

04kgm

(17-221bft). Check tappet clearance (see

Operation

17)

.

31

Fit a

new

gasket and replace the rocker

cover securing in position

with

the

two

nuts

and washers.

32

Replace all ancillaries.

33

Install the engine and gearbox assembly

(see

Operation

1 ) .

Operation 1 7 - Valve clearance

-tappet

adjustment

Tappet clearances are 0·

152

mm

(0

·

006

in)

cold,

0·254 mm

(0

·

01

Oin) hot.

To

adjuat

1 Remove rocker cover, secured

by

two

nuts.

2 Remove spark plugs.

3 Turn engine in normal running direction in

order

to

open and close the valves and check

The engine

in the

following

order:

No

'. 1 valve

with

No

. 8 valve fully open

No

. 2 valve

with

No

. 7 valve fully open

No

. 3 valve

with

No. 6 valve fully open

No

. 4 valve

with

No. 5 valve

fully

open

No

. 5 valve

with

No

. 4 valve fully open

No

. 6 valve

with

No

. 3 valve

fully

open

No

. 7 valve

with

No

. 2 valve fully open

No.

8 valve

with

No

. 1 valve

fully

open

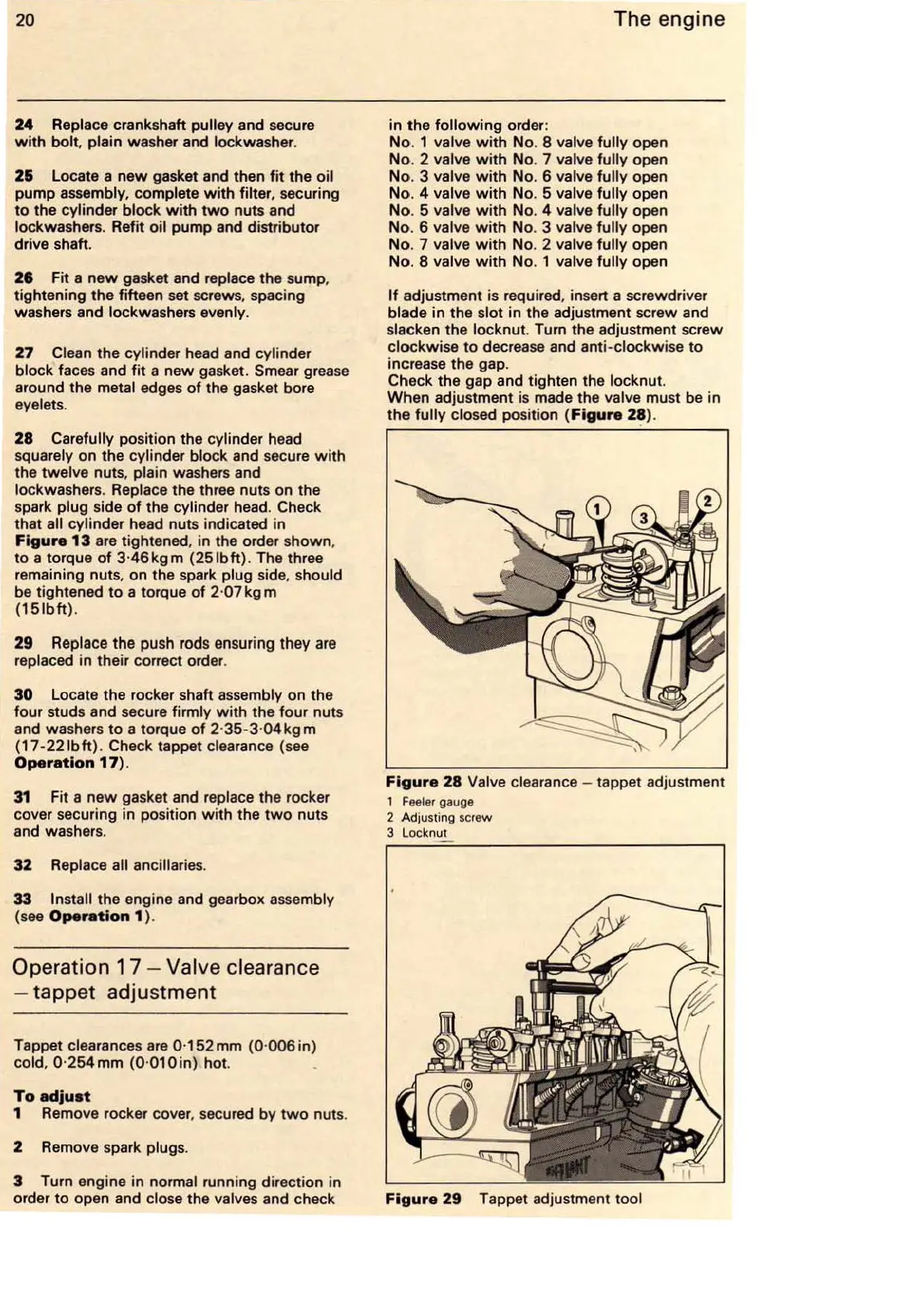

If

adjustment is required, insert a screwdriver

blade

in

the slot in the adjustment screw and

slacken the locknut. Tum the adjustment screw

clockwise

to

decrease and anti-clockwise

to

increase the gap.

Check the gap and tighten the locknut.

When adjustment

is

made the valve must be in

the

fully

closed position

(Figure

2~

).

Figure

28

Valve clearance - tappet adjustment

1

Feeler

gauge

2 Adjusting screw

3 Locknut

Figure

29

Tappet adjustment tool

Loading...

Loading...