Robin 8&0

Workshop

Manuel

Supplement

The engine

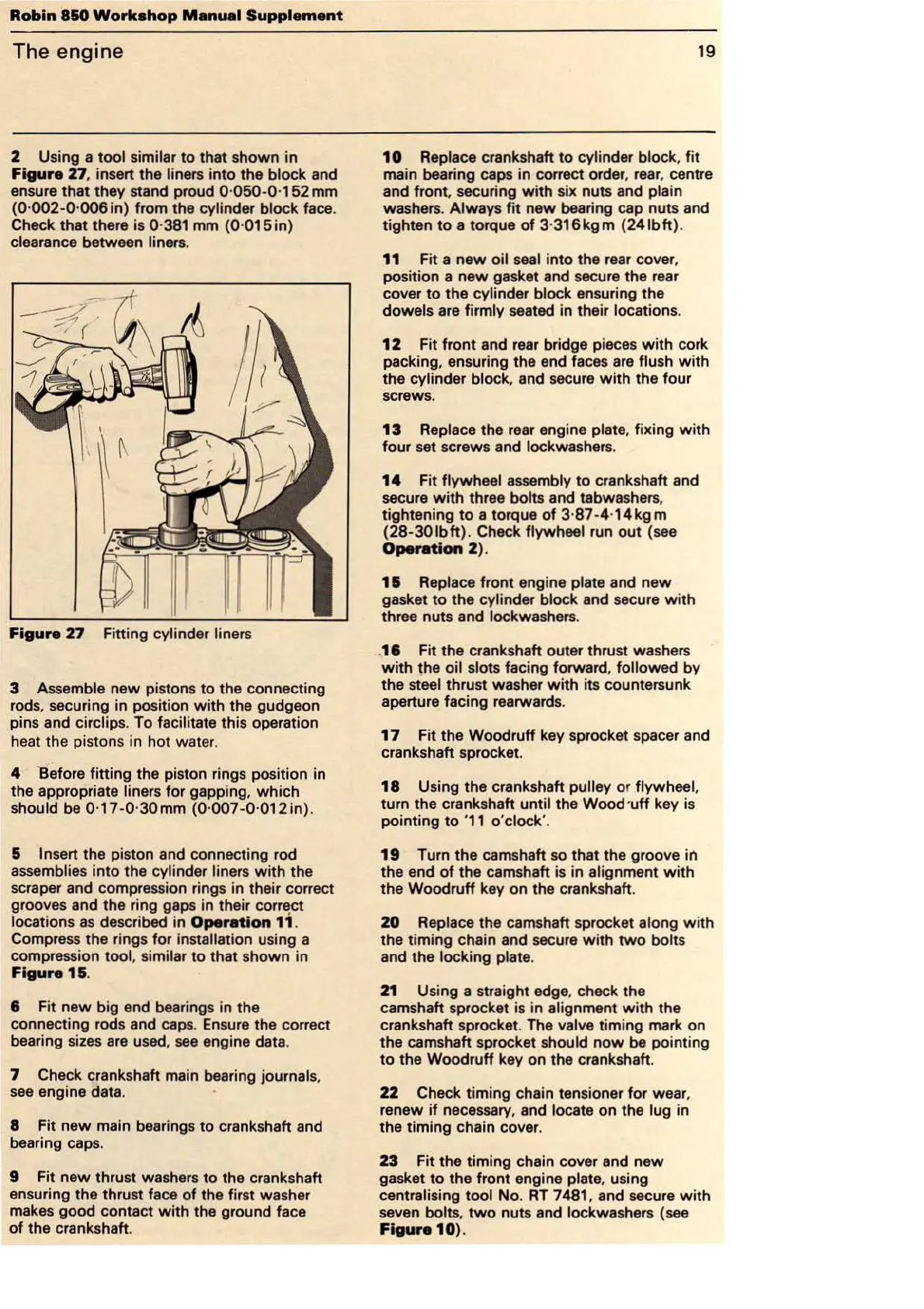

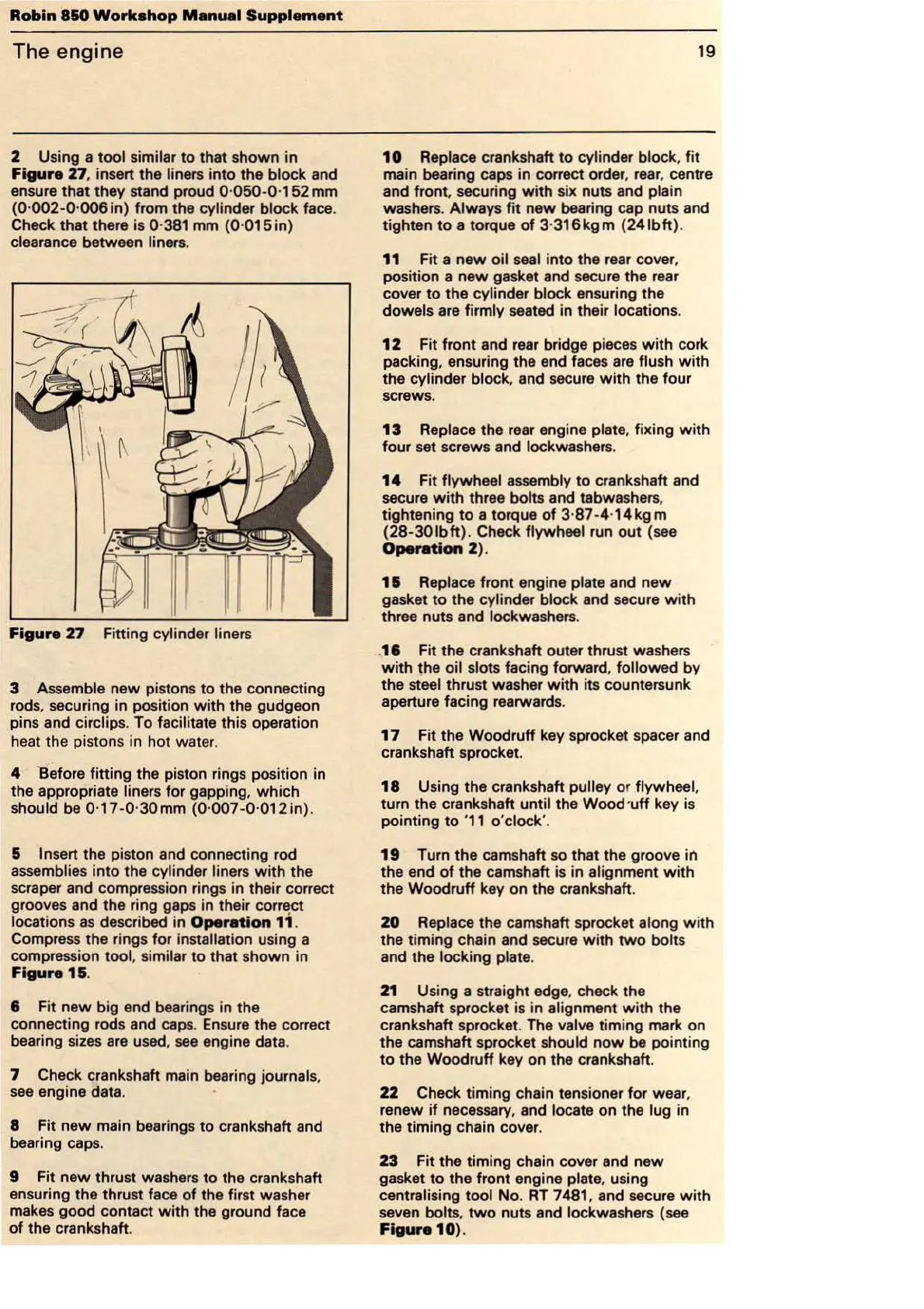

2 Using a

tool

similar

to

that shown

in

Figure

27

, insert the liners into the block and

ensure that they stand proud 0·

050

-0·

152

mm

(0·002-0·

006

in) from the cylinder block face.

Check that there is 0·

381

mm

(0

·

015in)

clearance between liners.

Figure

27

Fitting cylinder liners

3 Assemble new pistons

to

the connecting

rods. securing in position

with

the gudgeon

pins and circlips. To facilitate this operation

heat the pistons in hot water.

4 'Before fitting

the

piston rings position in

the appropriate liners for gapping. which

should be 0·17

-0·3

0mm

(0

·

007-0

·

012in)

.

& In

se

rt the pis

ton

and connecting rod

assemblies into the cylinder liners with the

scraper and compression rings in their correct

grooves and the ring gaps in their

corn~ct

locations

as

described in Operation

11

.

Compress the rings for installation using a

compression tool. similar

to

that shown in

Figure

1&

.

6 Fit

new

big end bearings in the

connecting rods and caps. Ensure the correct

bearing

sizes

are

used,

see

engine data.

7 Check crankshaft main bearing journals,

see

engine data.

8 Fit

new

main bearings

to

crankshaft and

bearing caps.

9 Fit new thrust washers

to

the crankshaft

ensuring the thrust face

of

the first washer

makes good contact with the ground face

of

the crankshaft.

19

10

Replace crankshaft

to

cylinder block, fit

main bearing caps in correct order, rear, centre

and

front

, securing

with

six nuts and plain

washers. Always

fit

new

bearing cap

nu

ts and

tighten

to

a torque

of

3·

316kgm

(241bft).

11

Fit a

new

oil seal into the rear cover,

position a

new

gasket and secure the rear

cover

to

the

cylinder block ensuring the

dowels are firmly seated in their locations.

12

Fit front and rear bridge pieces

with

cork

packing, ensuring the end faces

are

flush

with

the cylinder block, and secure

with

the four

screws.

13

Replace the rear engine plate, fixing

with

four set screws and lockwashers.

14

F

it

flywheel assembly

to

crankshaft and

secure

with

three bolts and tabwashers,

tightening

to

a torque

of

3·

87

-4·

14kgm

(28-301bft). Check flywheel run

out

(see

Operation

2)

.

15

Replace fr

ont

engine plate and new

gasket

to

the cylinder block and secu

re

with

three nuts and lockwashers.

.

16

Fit the crankshaft outer thrust washers

with

the oil slots facing forward, followed by

the steel thrust washer

with

its countersunk

aperture facing rearwards.

17

Fit the Woodruff key sprocket spacer and

crankshaft sprocket.

18 Using the crankshaft pulley or flywheel,

turn the crankshaft until the Wood ·

uff

key is

pointing

to

'

11

o'clock'.

19

Turn the camshaft so that the groove in

the end

of

the camshaft is in alignment w

it

h

the Woodruff key on the crankshaft.

20

Replace the camshaft sprocket along

with

the timing chain and secure w ith

two

bolts

and the locking plate.

21

Using a straight edge, check the

camshaft sprocket is in alignment with the

crankshaft sprocket. The valve timing mark on

the camshaft sprocket should

now

be pointing

to

the Woodruff key

on

the crankshaft.

22

Check timing chain tensioner for wear,

renew

if

necessary, and locate on the lug in

the timing chain cover.

23

Fit the timing chain cover and new

gasket

to

the front engine plate, using

centralising tool

No

.

RT

7481 , and secure with

seven bolts,

two

nuts and lockwashers (see

Figure

10)

.

Loading...

Loading...