18

Operation

15

- Cylinder liner

replacement

Follow the dismantling procedure outlined in

operations 1

to

14

and then continue

as

follow

s:

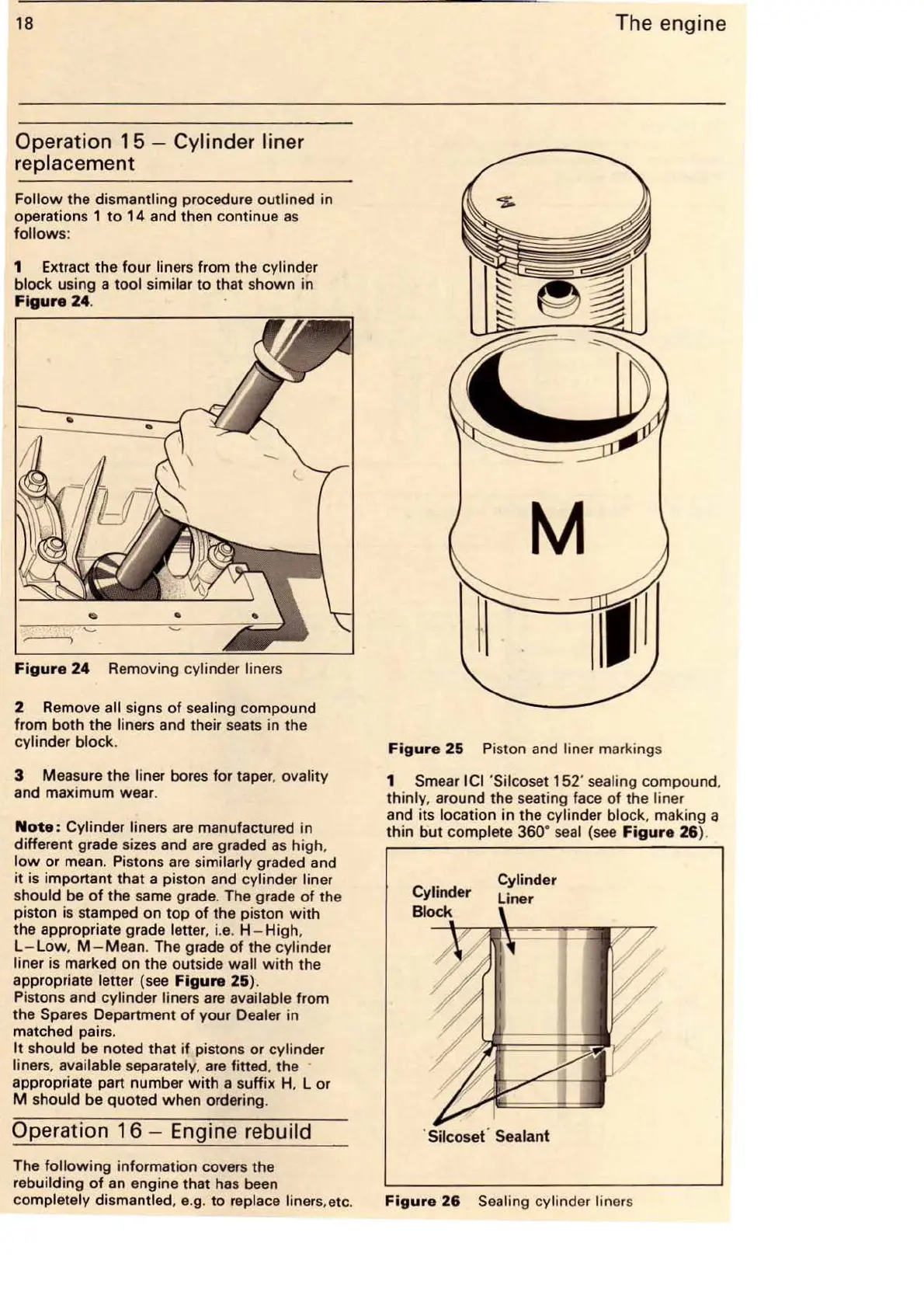

1 Extra

ct

the four liners from the cylinder

block using a

tool

similar

to

that

shown in

Figure

24

.

Figure

24

Removing cylinder liners

2

Rem

ove all signs

of

sealing compound

from both t

he

liners and their seats in the

cylinder block.

3 Measure the liner bores for taper. ovality

and maximum wear.

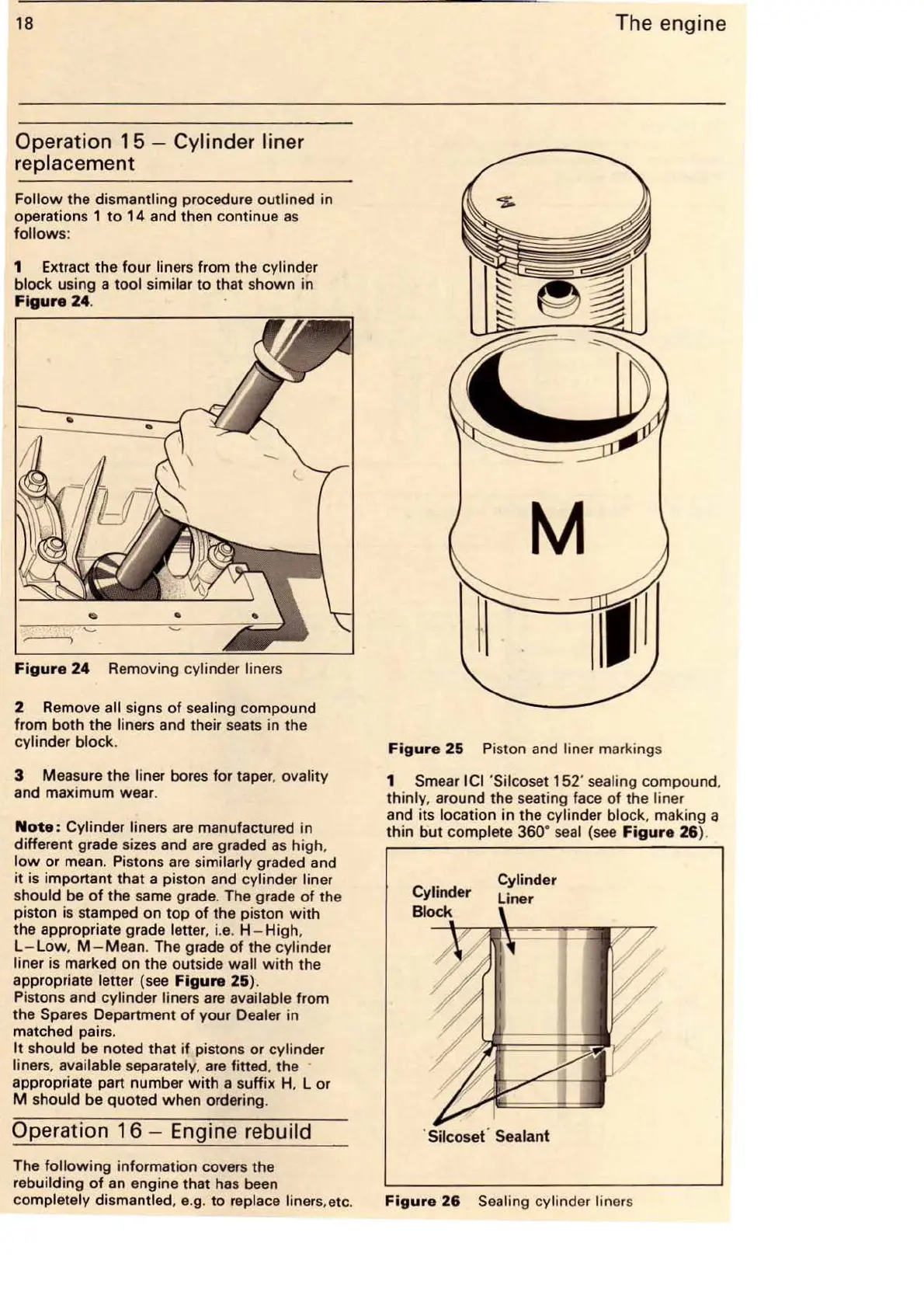

Note:

Cylinder liners are manufactured in

different grade sizes and

are

graded

as

high,

low

or mea

n.

Pistons are similarly graded and

it is important

that

a piston and cylinder liner

should

be

of the

sa

me gr

ade.

The grade

of

the

piston is sta

mp

ed on

top

of

the piston

with

the appropriate grade letter, i.e. H- High,

L-

Low

, M - M

ea

n. The grade

of

th

e cylinder

liner is marked on the outside

wall

with

the

appropriate letter (see

Figure

26).

Pistons and cylinder liners

are

available from

the Spares Department

of

your Dealer in

matched pair

s.

It

should be noted that

if

pistons

or

cylinder

liners, available separately, are fitted. the

appropriate part number

with

a suffix H. L or

M should be quoted when ordering.

Operation

16

- Engine rebuild

The

following

infor

mation covers the

rebuilding

of

an

engine that has been

complete

ly

dismantled, e.g.

to

replace liners.etc.

The engine

M

Figure

25

Pi

ston and liner markings

1 Smear ICI

'S

ilcoset

152

' sealing compound,

thinly, around the seating face

of

the liner

and its location in the cylinder

block, making a

thin

but

co

mplete

360

" seal (see

Figure

26

).

Cylinder

Liner

· Silcoset · S

ea

la

nt

Figure

26

Sealing cylinder liners

Loading...

Loading...