The gearbox Section G

13

Repeat operation

for

two

remaining balls.

14

Slide 3r

d/4th

synchro sleeve along synchro

body until

it

clicks

into

position.

Note:

Ensure the sleeve is

not

pushed too far,

otherwise the synchro

balls and thrust blocks

will

be

disturbed.

15

Reposition mainshaft in vice

or

assembly

pot

to facilitate

1st/2nd

synchro

body

assembly.

16

Fit springs and plungers to synchro body.

17

Slide

1st/2nd

synchro sleeve over synchro

body

leaving sufficient room to enable fitment

of

thrust blocks and balls. Ensure the teeth

of

the synchro sleeve are facing forward.

18

Fit the three thrust blocks, leaving synchro

ball seatings completely visible.

19

Seat synchro

body

ball in thrust block,

press

ball

down

onto

plunger and slide thrust

block between sleeve and synchro

body

.

20

Repeat operation

for

two

remaining balls.

21

Position baulk ring on 1st speed gear.

22

Fit 1st speed gear bush into its location in

gear

body

.

23

Apply

'Mo

lygr

ease

799' to gear bush and

then

fit

into

1st gear.

24

Pos

it

ion 1st gear, including bush and baulk

ring,

onto

mainshaft splined end.

25

Rotate 1st gear bush, until

it

fully

locates

in the bush key seated in 1st

/2n

d synchro

body

.

Note

: Handle mainshaft gear cluster

with

care

to

prevent synchro sleeves, etc. from being

disturbed.

Primary gear assembly

To

dismantle

1 Using circlip pliers General Tool N

o.

7066

remove Circlip securing front bearing

to

primary

gear.

2 Remove spacer and front bear

in

g from

primary gear.

3 Withdraw needle

roller bearing from inside

primary gear body. This bearing may have been

removed

with

mainshaft assembly.

4

Inspect front bearing and needle roller

bearing

for

wear, renewing

if

necessary.

5 Replace components in reverse order.

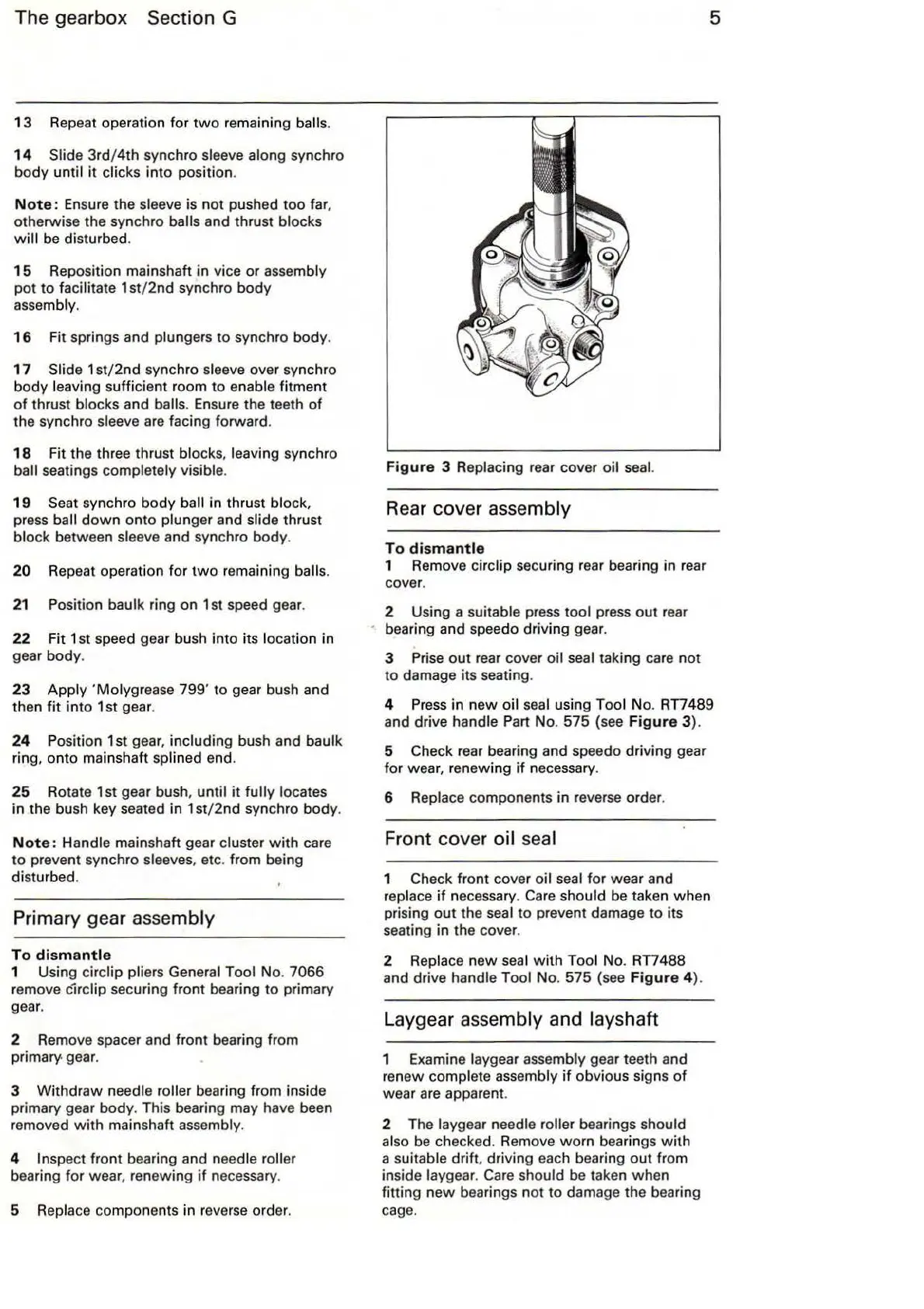

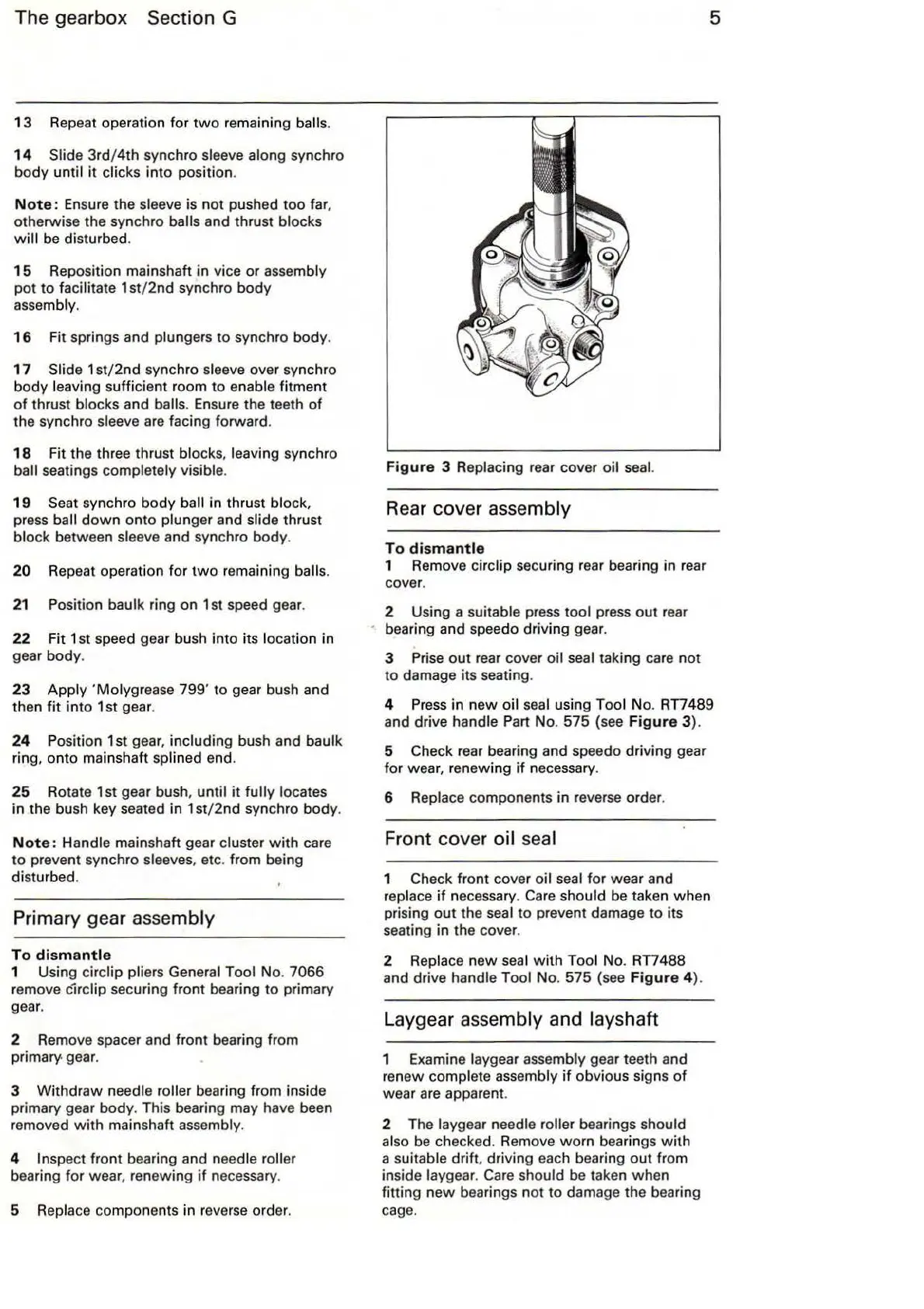

Figure

3 Replacing rear cover

oi

l seal.

Rear

cover assembly

To

dismantle

1 Remove circlip securing rear bearing in rear

cover.

2 Using a suitable press tool press

out

rea

r

bearing and speedo driving gear.

3 Prise

out

rear cover oil seal taking care

not

to damage its seating.

5

4

Press

in

new

oil seal using Tool

No

.

RTI489

and drive handle Part No. 575 (see

Figure

3).

5 Check rear bearing and speedo driving gear

for

wear, renewing

if

necessary.

6 Replace components in reverse order.

Front cover oil seal

1 Check front cover oil seal

for

wear and

replace

if

necessary.

Ca

re

should be taken when

prising

out

the seal

to

prevent damage to its

seating in the cover.

2 Replace new seal

with

Tool No.

RTI488

and

dr

iv

e handle Tool No. 575 (see

Figure

4).

Laygear assembly and layshaft

1 Examine laygear assembly gear teeth and

renew complete assembly

if

obvious signs

of

wear are apparent.

2 The laygear needle

roller bearings should

also

be

checked. Remove

worn

bearings

with

a suitable drift, driving each bearing

out

from

inside laygear. Care should be taken when

fitting

new

bearings n

ot

to

damage the bearing

cage.

Loading...

Loading...