The gearbox Section G

Figur

e 4 Replacing fro

nt

cover oil seal.

3 If signs

of

scoring are apparent on the

layshaft, due to

worn

needle roller bearings, it

will

have to

be

replaced.

Rever

se

roller gear assembly and

shaft

1 Check reverse gear teeth and renew

assembly

if

necessary.

2 Drive

out

worn bushes

with

a suitable drift

and

fit

n

ew

ones ensuring the e

nd

faces

of

the

bushes are

flush

with

the gear faces.

3

Check reve

rse

gear shaft for scoring and

replace

if

nec

essa

ry.

To

re

assemble

th

e gearbox

1 Re

fit

reverse

idl

er

gear and shaft into gearbox

case

,

with

shaft selector groove to the rear.

2 Position

lay gear assembly

with

its th

ru

st

washer in b

ase

of gearbox.

3 Refit primary gear assembly

into

bell

housing location.

Not

e:

Drive carefully

into

position until

bearing retaining ring is flush

with

case.

4 Feed in mainshaft assembly, taking

ca

re

not

to dislodge synchro thrust blocks and balls. ·

5 Replace rear cover

with

its gasket to

within

6·35mm

(0

·25in)

of

the gearbox face to allow

rotary movement and facilitate positioning

of

layshaft.

6 Turn gearbox on its

top

face and feed

layshaft through thrust washer into laygear

assembly

unt

il

it

mates with its bore in rear end

of

box.

Note

: Tang end on layshaft must

be

at front.

6

7 Position tang

of

reverse shaft to engage

with

horizontal slot in rear cover, and force rear

cover

fully

home.

8 Locate rear suppon mounting, and eanhing

strap

to

rear cover and then secure rear cover

with six

1 UNC set screws and lockwasher

s.

9 Replace coupling flange on mainshaft

spline,

fit

washer and tab washer, a

nd

secure

with

i UNF nut, tightening to a torque

of

6·92kg m (501b ft). Be

nd

over tab washer

to

lock coupling flange

nut

.

10

Replace reverse, 1s

t/2

nd

and 3rd/ 4th

select

or

forks.

11

Replace the

two

interlocking balls in the

cross

drilling bell housing, locating in position

with grease.

12

Line

up

reverse selector shaft in

se

lector

fork

and drive home mills retaining pins.

13

Ensuring

in

terlock pin is

in

position,

replace 1st/ 2nd selector shaft

into

se

lector fork

and lever. Secure in position

with

mills pins.

14

Replace

3rd/4th

selector shaft into mating

fork and

lever, again retaining in position

with

mills pins.

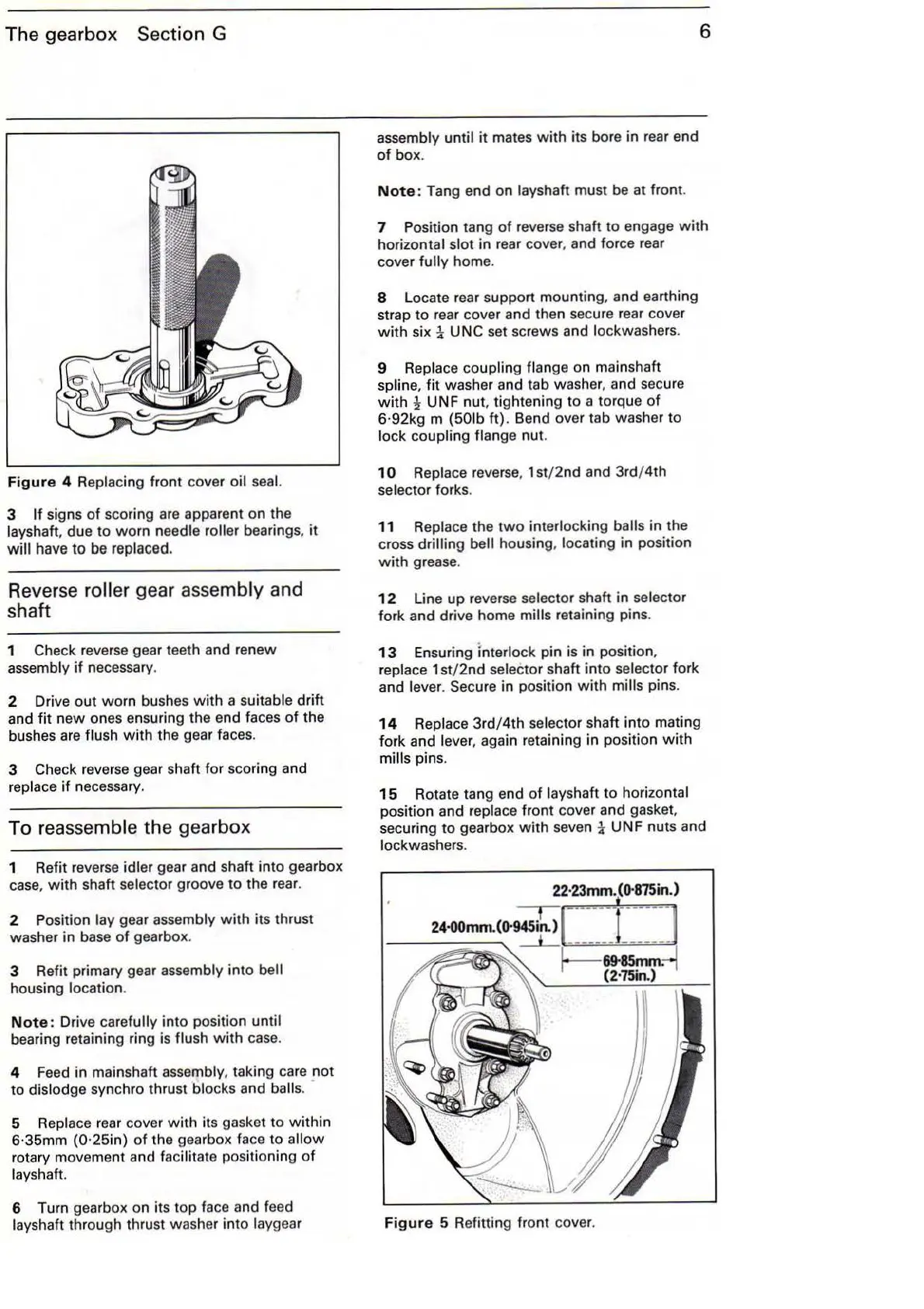

15

Rotate tang e

nd

of

layshaft to horizontal

position and replace front cover and gasket,

securing to gearbox

with

seven 1 UNF nuts and

lockwasher

s.

Figure

5 Refitting front cover.

Loading...

Loading...